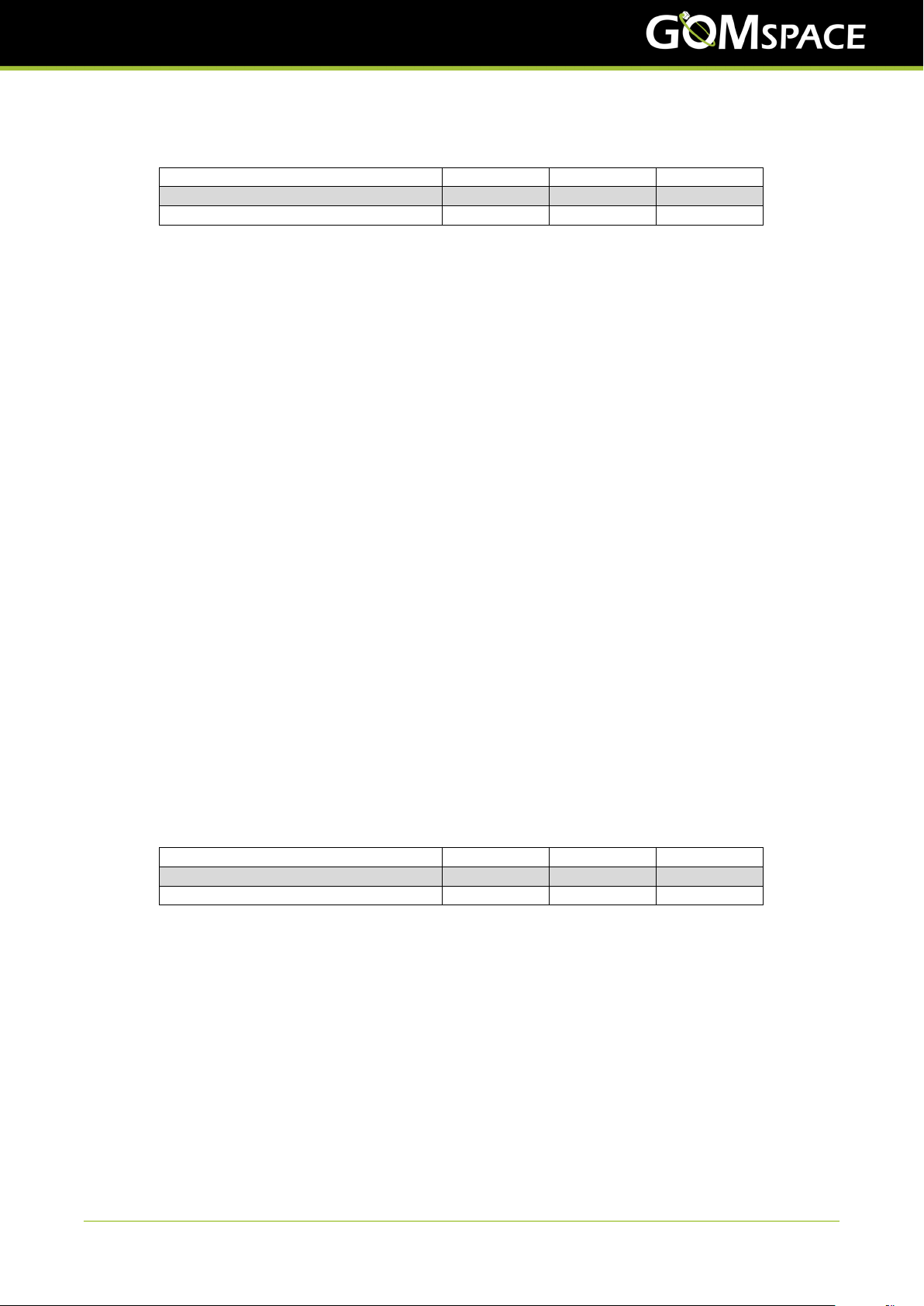

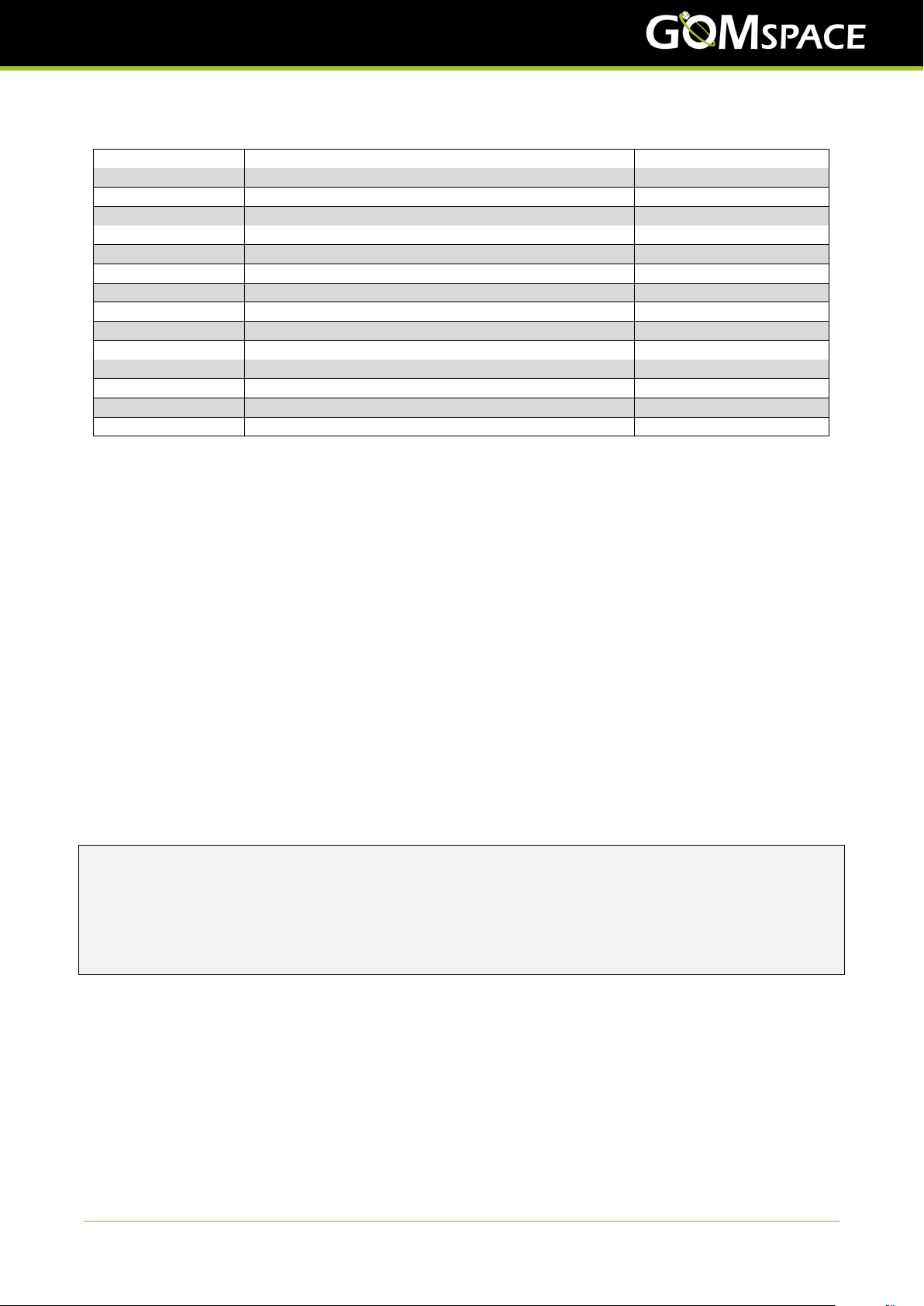

Table 4.1: Recommended settings for vbat_max_hi and

vbat_max_lo

Battery Pack Voltage 8 V 16 V 32 V

vbat_max_hi 8300 mV 16600 mV 33200 mV

vbat_max_lo 8150 mV 16300 mV 32600 mV

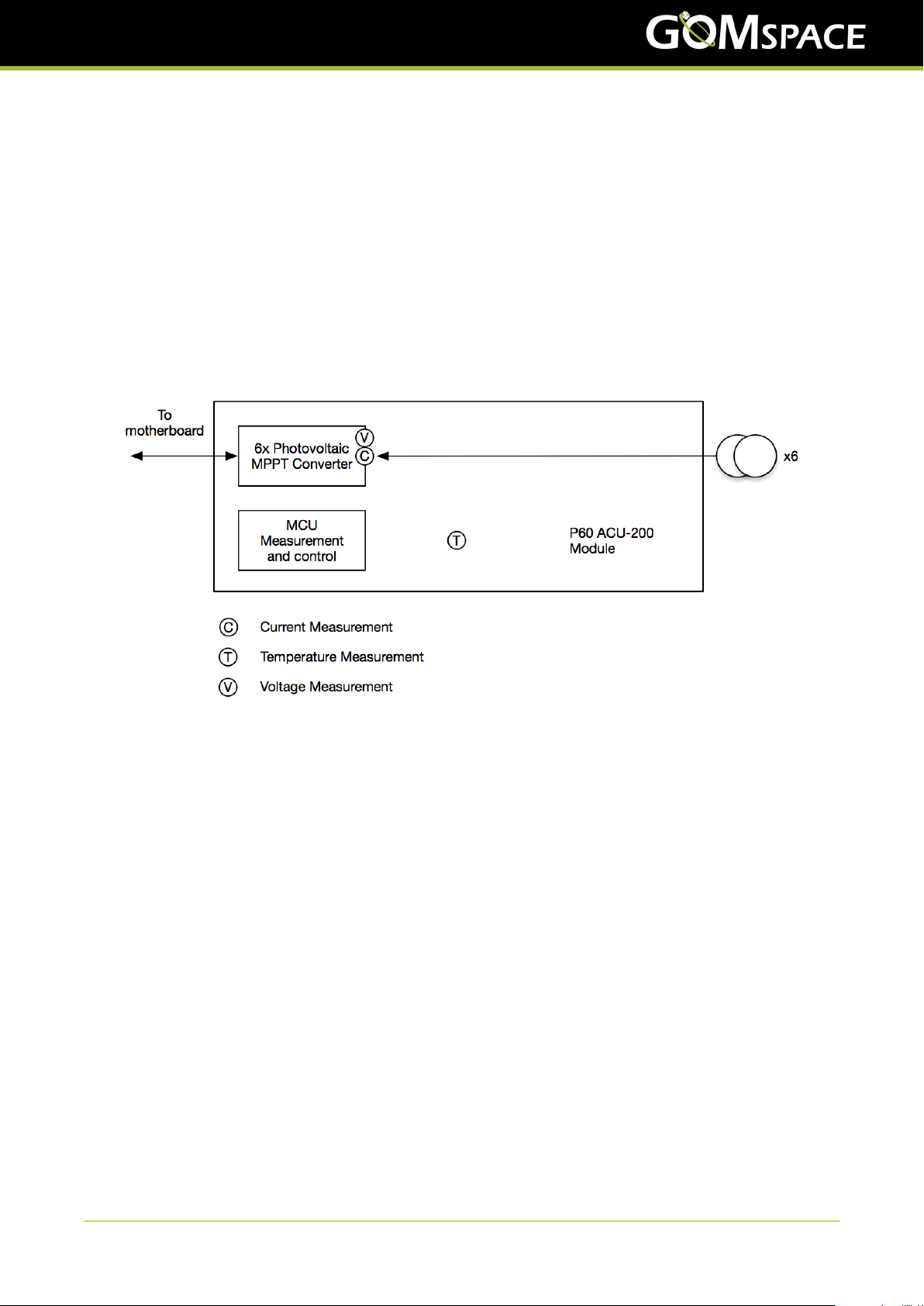

The ov_mode defines the photovoltaic converter behavior of the P60 ACU-200 when the battery is fully charged,

i.e. above the vbat_max_hi value.

When the battery voltage is above vbat_max_hi, the charging is minimised by setting the vboost voltage level

to the maximum value (27000 mV) or the minimum value (4300 mV), depending on the parameter ov_mode. If

ov_mode is 1, the vboost voltage level will be set to the minimum value (4300 mV). If ov_mode is 2, the vboost

voltage level will be set to the maximum value (27000 mV).

The default ov_mode is 2, defining that the photovoltaic input is open circuited when the battery is fully charged.

This mode is used on all spacecrafts with 8V, 16V and 32V battery pack, as long as each photovoltaic input

open circuit voltage is guaranteed to be below the maximum operation voltage of the battery pack. E.g. a 8V

battery pack requires an open circuit photovoltaic of no more than 8400 mV.

In special cases it may be desired to have a photovoltaic array with an open circuit input voltage slightly above

the max. battery voltage. If such a case cannot be avoided the ov_mode must be set to 1. When ov_mode

is 1, the photovoltaic input converter set point is as low as possible (4300 mV) when the maximum battery

voltage is reached. Note that in this case, a one-string photovoltaic panel (500 mA) still produces about 2.2 W.

It is recommended to have sufficient amount of subsystems powered ON in normal mode to avoid charging the

battery further.

If the battery is charged further, the P60 Dock will disconnect the battery as a final protection method until the

voltage is within safe operation again. Tripping the P60 Dock overvoltage battery protection may cause the

spacecraft to be power cycled, as the available photovoltaic input power might be insufficient.

4.2.2 Hardware protection

Both the P60 ACU-200 and the P60 Dock has hardware protection circuits to protect the battery. The P60

ACU-200 takes this into account when controlling the charging of the battery. If the battery voltage exceeds the

hardware protection high threshold, the charging will not resume until the battery voltage level has dropped be-

low the hardware protection low threshold. For security reasons, the hardware protection low and high threshold

are not configurable, but are listed here for reference:

Table 4.2: Hardware protection thresholds for battery voltage

Battery Pack Voltage 8 V 16 V 32 V

High threshold 8400 mV 16800 mV 33600 mV

Low threshold 7625 mV 15250 mV 30500 mV

4.3 Calibration Parameters

The P60 ACU-200 module has a set of calibration parameters for voltage and current measurements.

The calibrations parameters are configured from factory and normally don’t need to be changed.

For voltages, there is a gain parameter. The gain is a floating-point number.

For currents, there is a gain and an offset parameter. The gain is a floating-point number. The offset is a signed

16-bit integer that controls the offset in mA.

The following table lists the default nominal values for each calibration parameter:

© 2023 GomSpace A/S. All printed copies, and all electronic copies and versions except the one accessible on

the GomSpace A/S server, are considered uncontrolled copies used for reference only.

5

Manual P60 ACU 200

22 March 2023

MAN 1018434 2.0.2