Operating Instructions IG-1113

3

1 General information

Dear customer,

Thank you for choosing our model IG-1113D dispensing controller.To

ensure proper operation, please carefully read the following pages for

correct operating and maintenance instructions. Keep these instructions

handy for future reference. If you require further information or if you have

any questions please contact us directly.

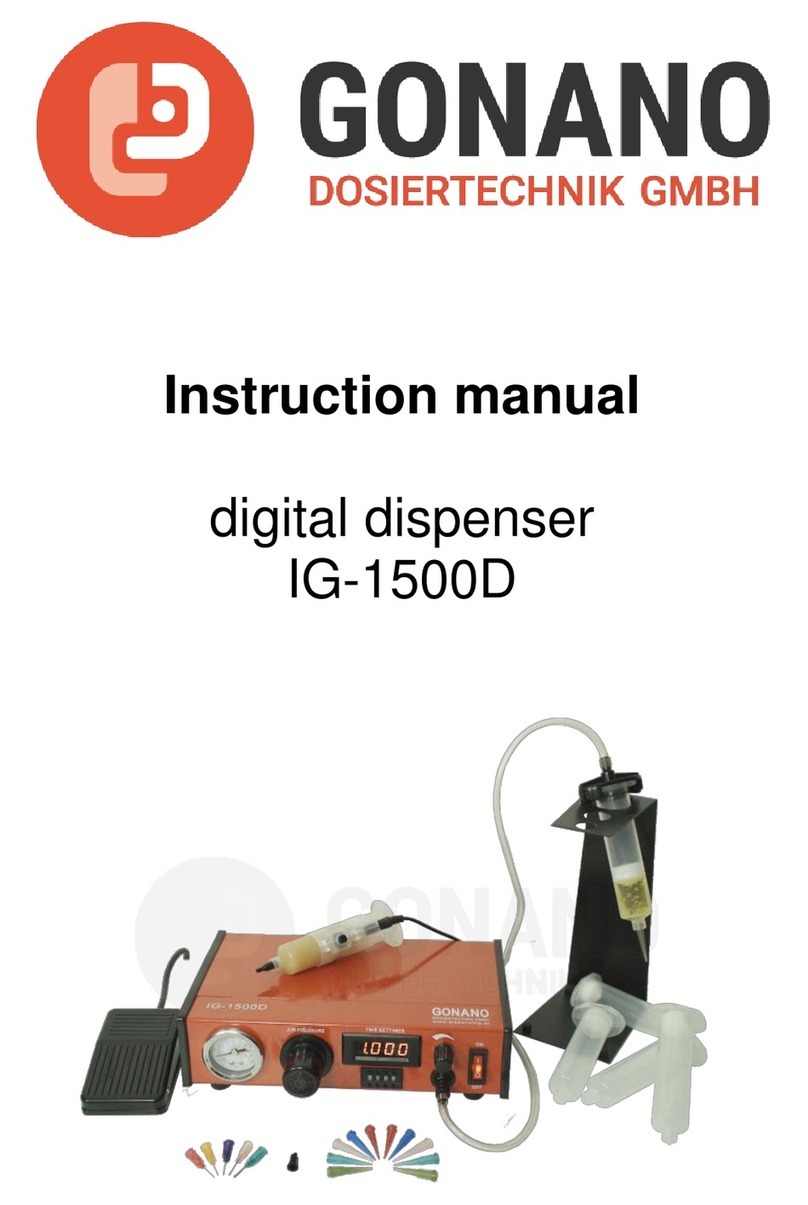

1.1 The IG-1113D

The IG-1113D dispensing controller series consists of two models which

have an output pressure of 0-1 and 0-7 bar respectivly, with no other

differences. For this reason, only the model IG-1113D is referred to below.

The IG-1113D is used for the precise dispensing of various liquids and

pastes. The operation is achieved by using compressed air along with

utilizing dispensing systems, such as small barrels containing 3 to 75 cc

of material. With the units compressed air regulator, the dispensing

pressure can be applied to the material and can be adjusted exactly to

dispense the correct amount of material.

In conjunction with the built in precise timer, distinct and precise amounts

of material can be dispensed.

1.2 Intended Use

The device is designed and constructed for commercial use. It is only to

be used for dispensing liquid and paste materials such as adhesives,

lubricants, various pastes, grease, oil, silicone and other similar materials.

Any other use is considered improper. If this device is used for other

purposes, personal injury or damage to property may result. The

manufacturer assumes no responsibility for consequences resulting from

improper use of the unit.

Non-intended use, which would also void the warranty, includes:

• Changes to the device not expressly recommended in the operating

instructions • Modifications to the unit and its components • Use of

incompatible or damaged spare parts • Use of non-approved accessories

or auxiliary equipment • Exceeding the approved and recommended

pressures