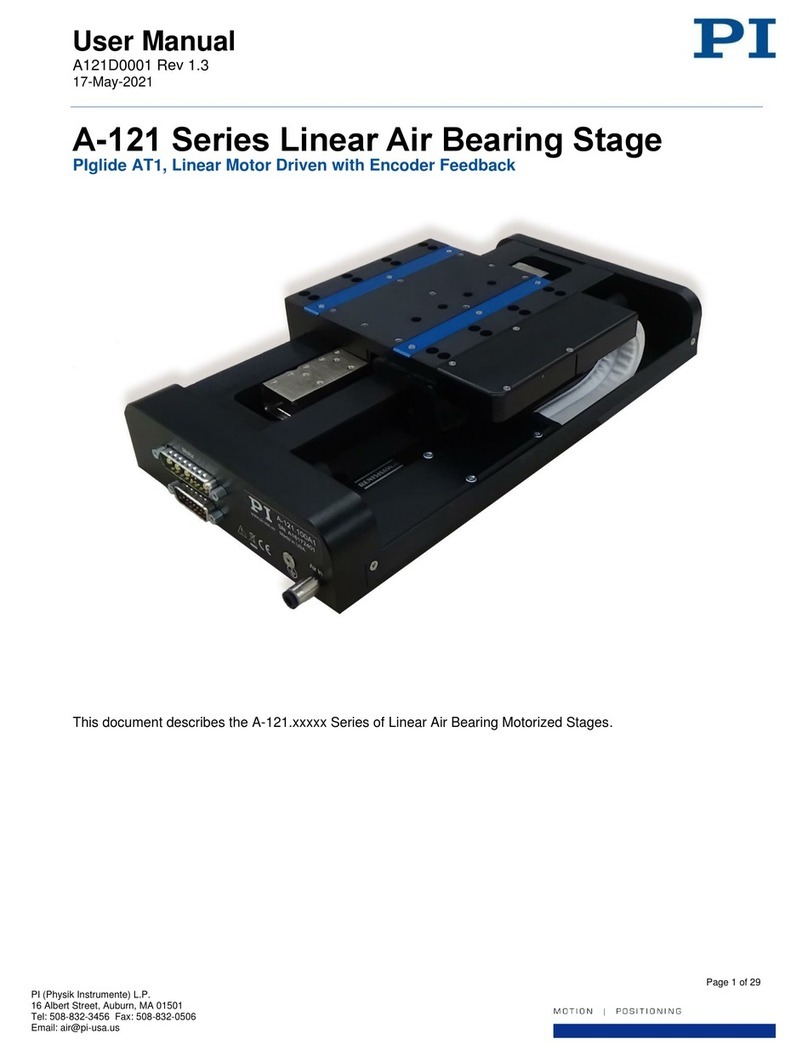

User Manual

PZ271E, valid for N-331

KSch, 1/18/2021

Physik Instrumente (PI) GmbH & Co. KG, Auf der Roemerstrasse 1, 76228 Karlsruhe, Germany Page 2 / 30

Phone +49 721 4846

Contents

About this Document 3

Symbols and Typographic Conventions............................................................................................................... 3

Figures ................................................................................................................................................................. 3

Other Applicable Documents .............................................................................................................................. 4

Downloading Manuals......................................................................................................................................... 4

Safety 4

Intended Use ....................................................................................................................................................... 4

Safety Precautions............................................................................................................................................... 5

Measures for Handling Vacuum-Compatible Products ....................................................................................... 6

Product Description 6

Model Overview .................................................................................................................................................. 6

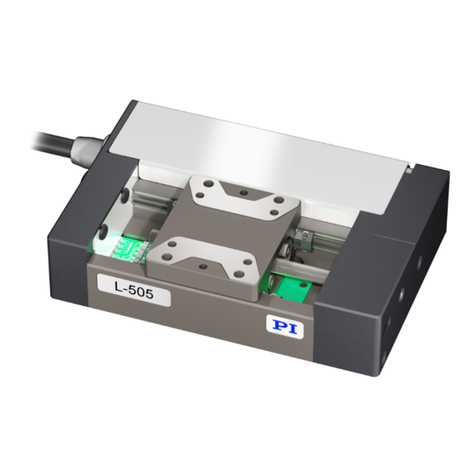

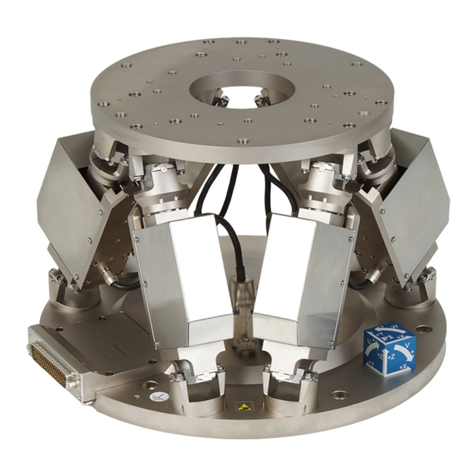

Product View ....................................................................................................................................................... 7

Product Labeling.................................................................................................................................................. 8

Scope of Delivery............................................................................................................................................... 10

Accessories ........................................................................................................................................................ 10

Suitable Electronics ........................................................................................................................................... 10

Unpacking 10

Installation 11

General Notes on Installation............................................................................................................................ 11

Connecting the N-331 to a Protective Earth Conductor ................................................................................... 12

Integrating the N-331 ........................................................................................................................................ 13

Fixing the N-331 by Its Base Body .................................................................................................................................13

Fixing the N-331 by Its Runner .......................................................................................................................... 15

Connecting the N-331 to the Electronics .......................................................................................................... 16

Startup and Operation 18

General Notes on Startup and Operation ......................................................................................................... 18

Startup and Operation....................................................................................................................................... 19

Discharging the N-331 ....................................................................................................................................... 20

Maintenance 20

General Notes on Maintenance ........................................................................................................................ 20

Cleaning the N-331 ............................................................................................................................................ 21

Customer Service 21

Technical Data 22

Specifications..................................................................................................................................................... 22