- 7 -

4

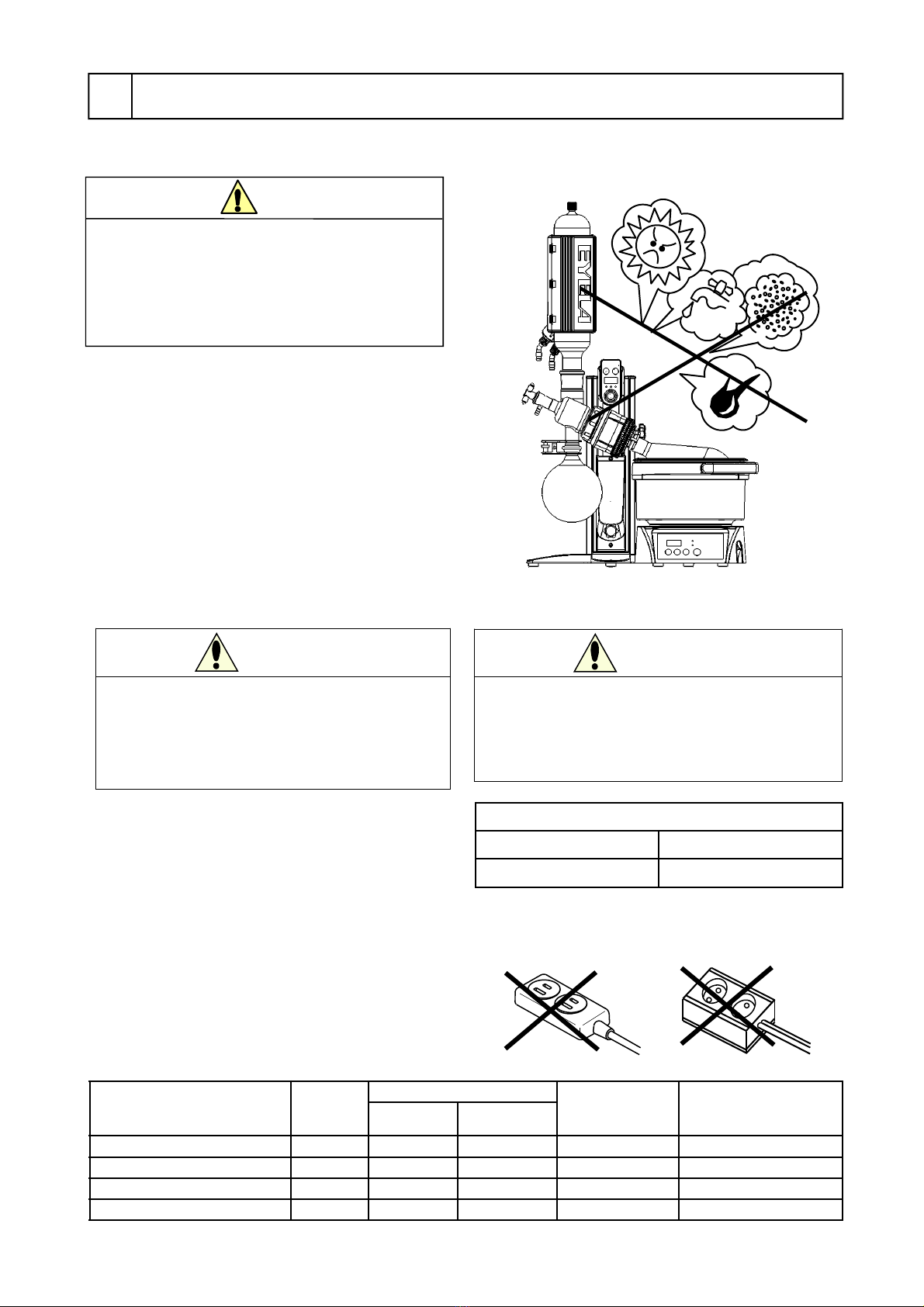

Warning

Do not use the branching socket

or table tap.

Burn-out of the cable or a fire may result from over

current.

Power supply to connect

Voltage Capacity

AC115~240V 15A

(1) Check the product type as well as the voltage, phase,

and capacity of power supply to be connected.

Power supply to be connected to the product is as

shown in the right.

(2) Check the receptacle of installation place.

※Do not connect the power plug yet ※First make

sure that the sheath of the power cord is not

damaged. Otherwise, an electric shock may result.

※Use the supplied power cord only.

A fire or an electric shock may result from

insufficient capacity.

Power cord specification

Name Cord No Cable Section area of

electric wire(AWG) Areas supported

Length O.D.

115V Power code A type 267699 Approx.2.0m Approx.5.8mm 0.8mm2(AWG18) North America

220V Power code O type 267698 Approx.1.8m Approx.5.7mm 0.75mm2(AWG18) China

220~240V Power code B type 267695 Approx.2.0m Approx.5.6mm 0.75mm2(AWG18) U.K., India

220~240V Power code C type 267697 Approx.2.0m Approx.5.6mm 0.75mm2(AWG18) Europe

※Never use a branching socket or a table tap for

connecting to the power supply.

4-1 Installation environment

Select a place that meets the conditions below

for installing this product:

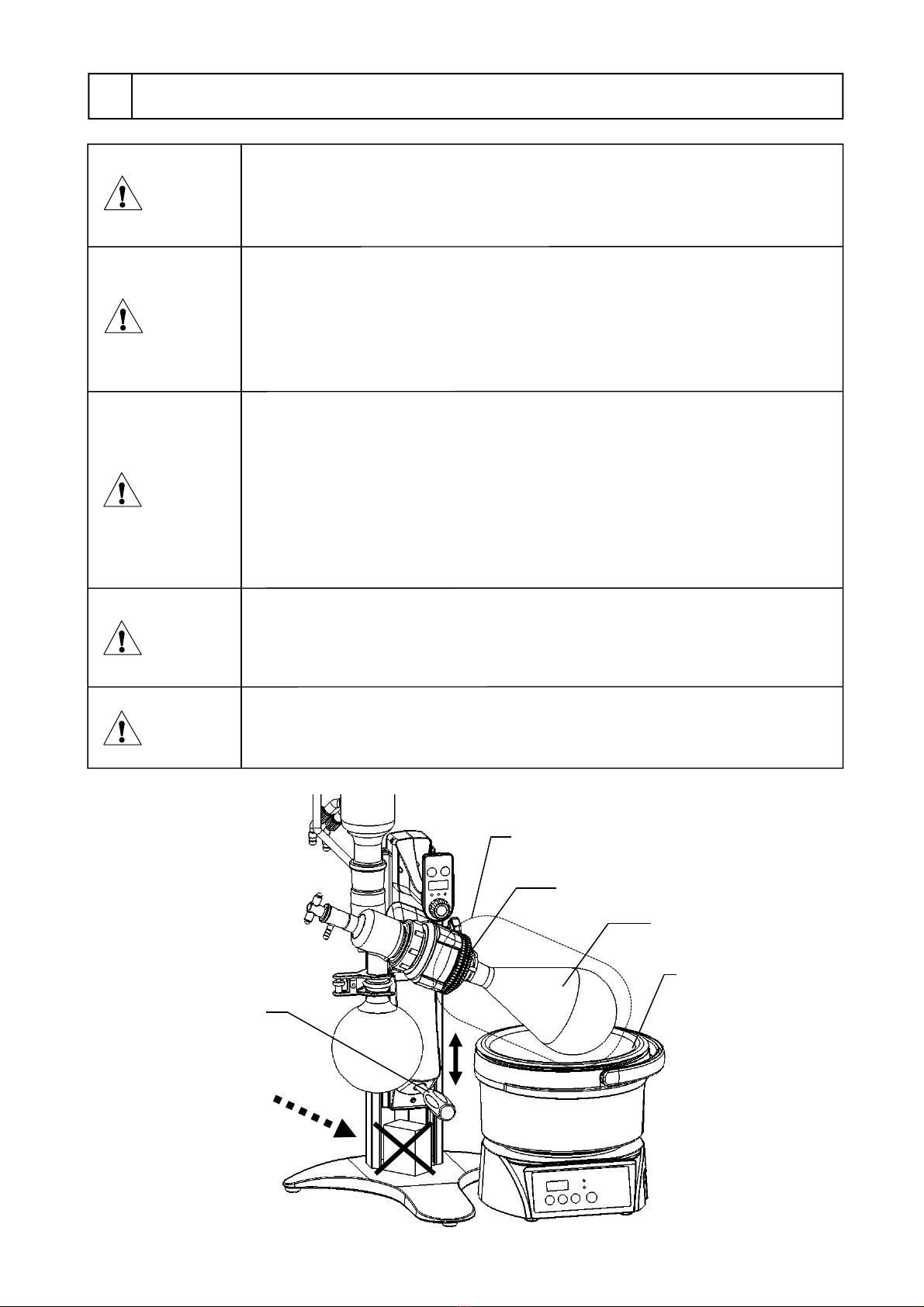

Never install the product in a

potentially hazardous atmosphere.

The product is not explosion-proof. Use in a

potentially hazardous atmosphere may cause a fire

or other accidents.

Warning

●Place free of flammable gas, liquid, or solid

materials in the vicinity of the product.

●Place where the ambient temperature can be kept

within a range of 5~35℃.

●Place free from condensation

●Place with less humidity and free from splashing

water

●Place with minimum dust

●Place free from direct sunshine

●Place where airy or well-ventilated

●Level, stable, and firm place

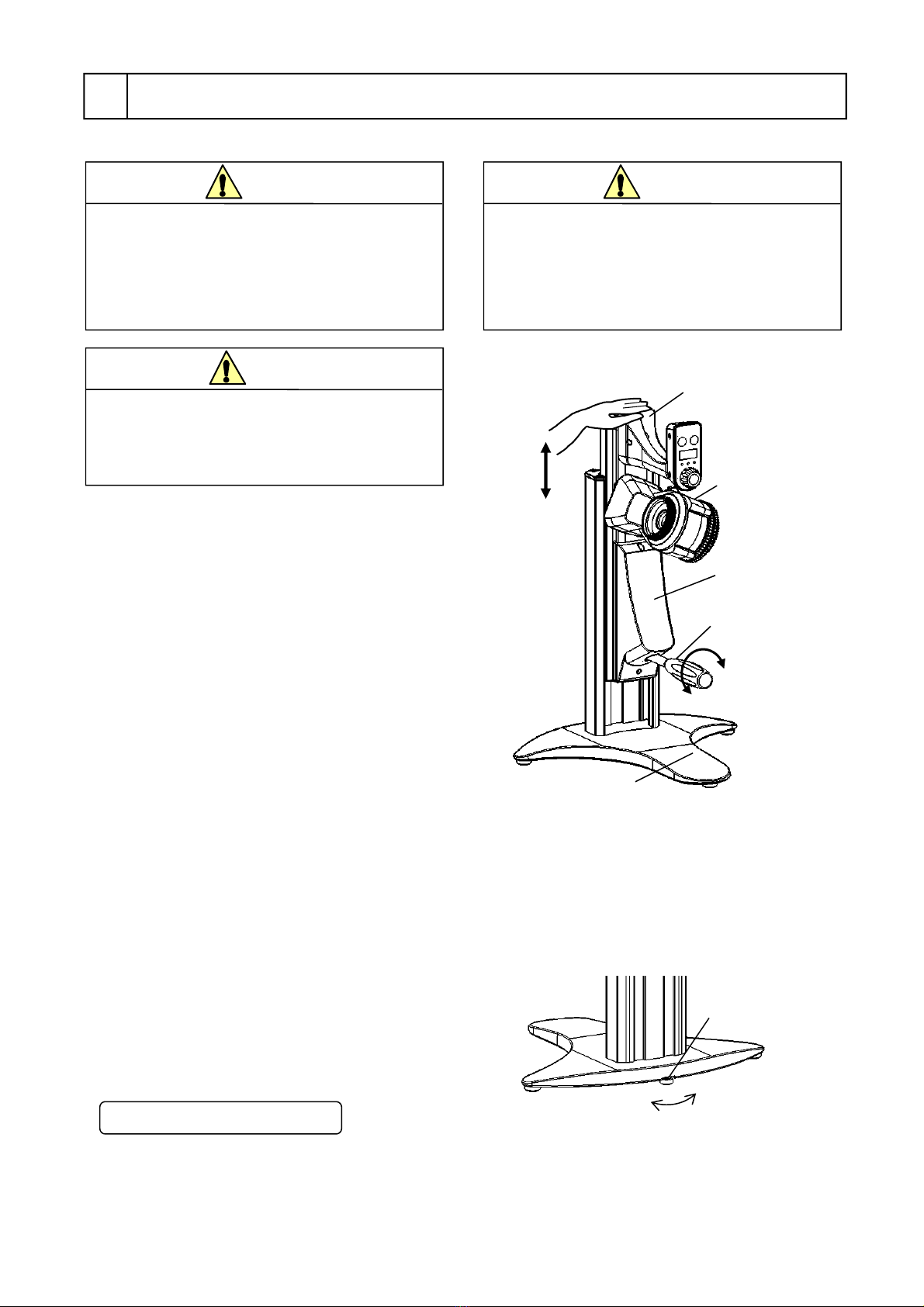

Installation

Warning

Confirm the voltage, phase, capacity,

and the type of receptacle of power

supply.

Wrong connection of power supply may cause fire or

electric shock

4-2 Connecting utilities