RAM‐PROJAN20121|Page

TableofContents

ImportantSafetyInstructions................................................................................................ 1

ElectricalPrecautions................................................................................................................ 1

OperationalPrecautions ........................................................................................................... 2

TheRAM‐PROReam‐A‐Matic® .............................................................................................. 2

HowItWorks ............................................................................................................................ 2

Forward/ReverseFootPedal .................................................................................................... 2

Operation.................................................................................................................................. 2

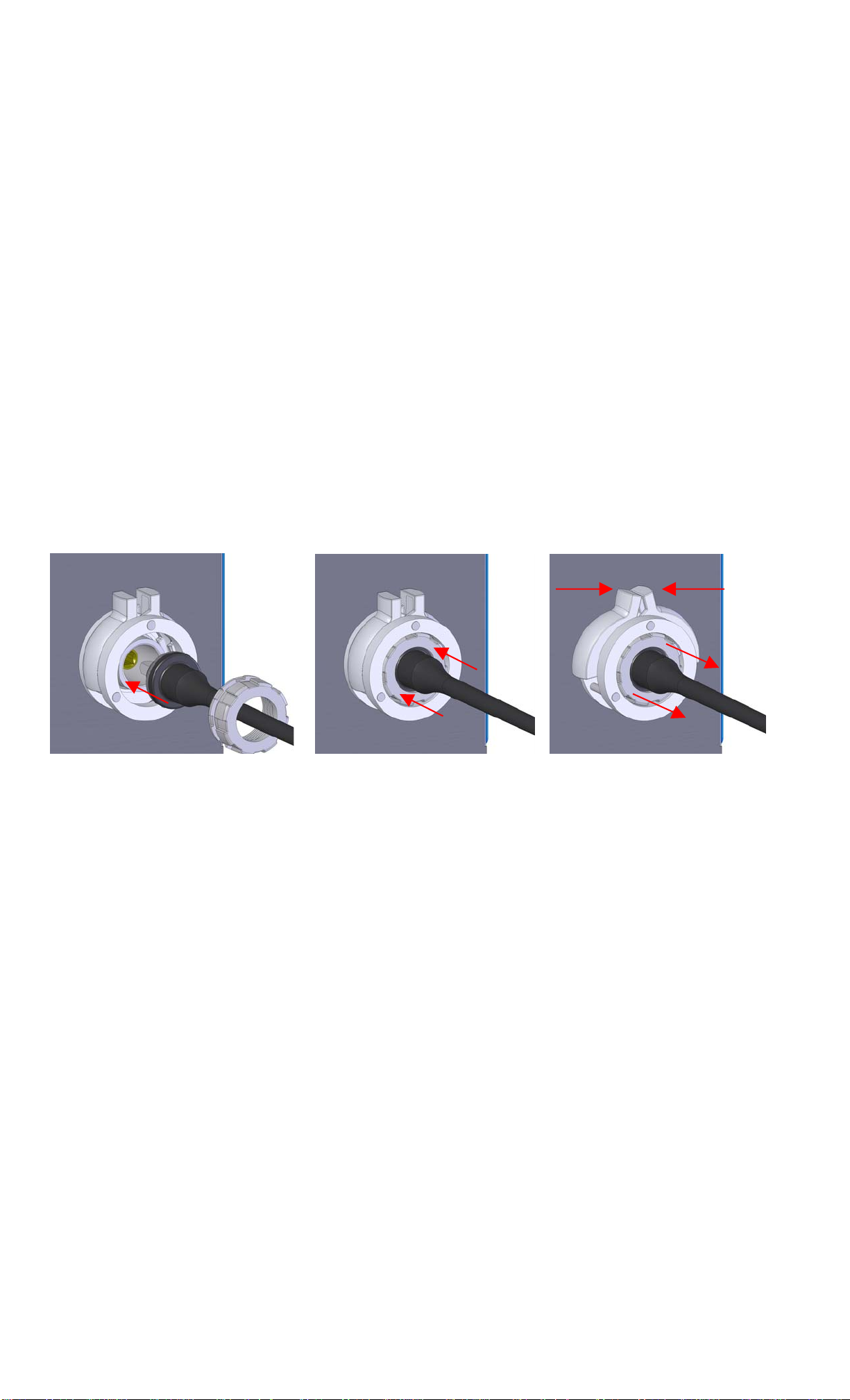

UsingtheQuick‐ConnectFlexibleShaft(PROShaftsOnly)....................................................... 3

Storage...................................................................................................................................... 3

Maintenance............................................................................................................................. 3

Specifications............................................................................................................................ 3

WarrantyInformation............................................................................................................... 3

Troubleshooting........................................................................................................................ 4

WiringDiagram.........................................................................................................................4

PartsList/Breakdown................................................................................................................ 5

ThankyouforpurchasingGoodway’s“RAM‐PRO”REVERSINGTUBECLEANERWITHQUICK‐CONNECTSHAFT.

Weappreciateyourbusinessandlookforwardtoservingyouinthefuture.AswithallGoodwayproducts,you

canbeassuredthatthefinestqualitycomponentsandworkmanshiphavegoneintothismachine.

PleasetakeafewminutestoreadthefollowingOperatingandMaintenanceInstructions.Bycarefully

followingtheinstructions,youwillobtainyearsoftroublefreeservicefromthisproduct.Pleasepayparticular

attentiontothesafetyinstructionsandexercisecautionwhenusingthismachine.

SAVETHESEINSTRUCTIONS!!

ImportantSafetyInstructions

•Readallinstructionsbeforeusingunit.Failuretofollowallinstructionsmayresultinseriousinjury.

•Keepobjects,looseclothing,hairandbodypartsawayfromopeningsandmovingparts.

•Donotoverreachorstandonunstablesupport.Keepgoodfootingandbalanceatalltimes.

•Stayalert–watchwhatyouaredoing!

•Donotoperatetheproductwhenfatiguedorundertheinfluenceofalcoholordrugs.

•Keepoperationareaclearofallpersons.

•Usepersonalsafetyequipment.Alwaysweareyeprotection.Dustmask,non‐skidrubbersolesafetyshoes,

hardhat,glovesandhearingprotectionarerecommended.

•UseonlyGOODWAYrecommendedaccessoriesandreplacementparts.

ElectricalPrecautions

•Neverexposetheunittorainortheelements.Storeunitindoorsinacool,dryarea.

•Makecertainthatthepowersourceconformstotherequirementsoftheequipment.

•Forproperprotectionthisproductmustbegrounded.Alwaysplugthepowercordintoaproperly

groundedreceptacle.Improperconnectionoftheequipment‐groundingconductorintroducesriskof

electrocution.Checkwithaqualifiedelectricianorservicepersonnelifyouareindoubtastowhetheran

outletisproperlygrounded.

•DANGER:Neverremovethegroundingprongfromthepowercordplugoruseanadapterthateliminates

ground.

•ThisunitisequippedwithaGroundFaultCircuitInterrupter(GFCI)attheplugendofthecordfor

electrocutionprotection.DONOTREMOVETHISDEVICE!!Ifreplacementoftheplugorcordbecomes

necessary,useonlyidenticalreplacementpartsthatincludeGFCIprotection.

•WARNING:Toreducetheriskofelectrocution,keepallconnectionsdryandofftheground.Donothandle

theunitorelectricalplugwithwethands.

•Whenunpluggingthepowercord,grasptheplug–notthecord.

•Unplugthepowercordwhenservicingtheunitorleavingthemachineunattended