2

93-ACC-BRUSHLESS 04/06/2017

Table of Contents

INTRODUCTION.............................................................................................................2

GENERAL.......................................................................................................................2

IMPORTANTSAFETYINSTRUCTION ...........................................................................3

GENERAL FEATURES...................................................................................................4

SET-UP...........................................................................................................................5

ADJUSTMENT................................................................................................................6

OPERATION...................................................................................................................6

OPERATING:..................................................................................................................7

MAINTENANCE..............................................................................................................8

TROUBLESHOOTING..................................................................................................16

INTRODUCTION

Thank you for purchasing this Goodway conveyor cleaner. We

appreciate your

business and look forward to serving you in the

future. As with all Goodway

products, you can be assured that the

finest quality components and workmanship

have gone into this machine.

Please take a few minutes to read the following Operating and Maintenance

Instructions. By carefully following the instructions, you will obtain years of trouble

free service from this product. Please pay

particular attention to the safety

instructions and exercise caution when using this machine.

We are here to serve you!

For Sales call 1-800-333-7467

For Service call 1-800-370-2855

Goodway Technologies Corp.

GENERAL

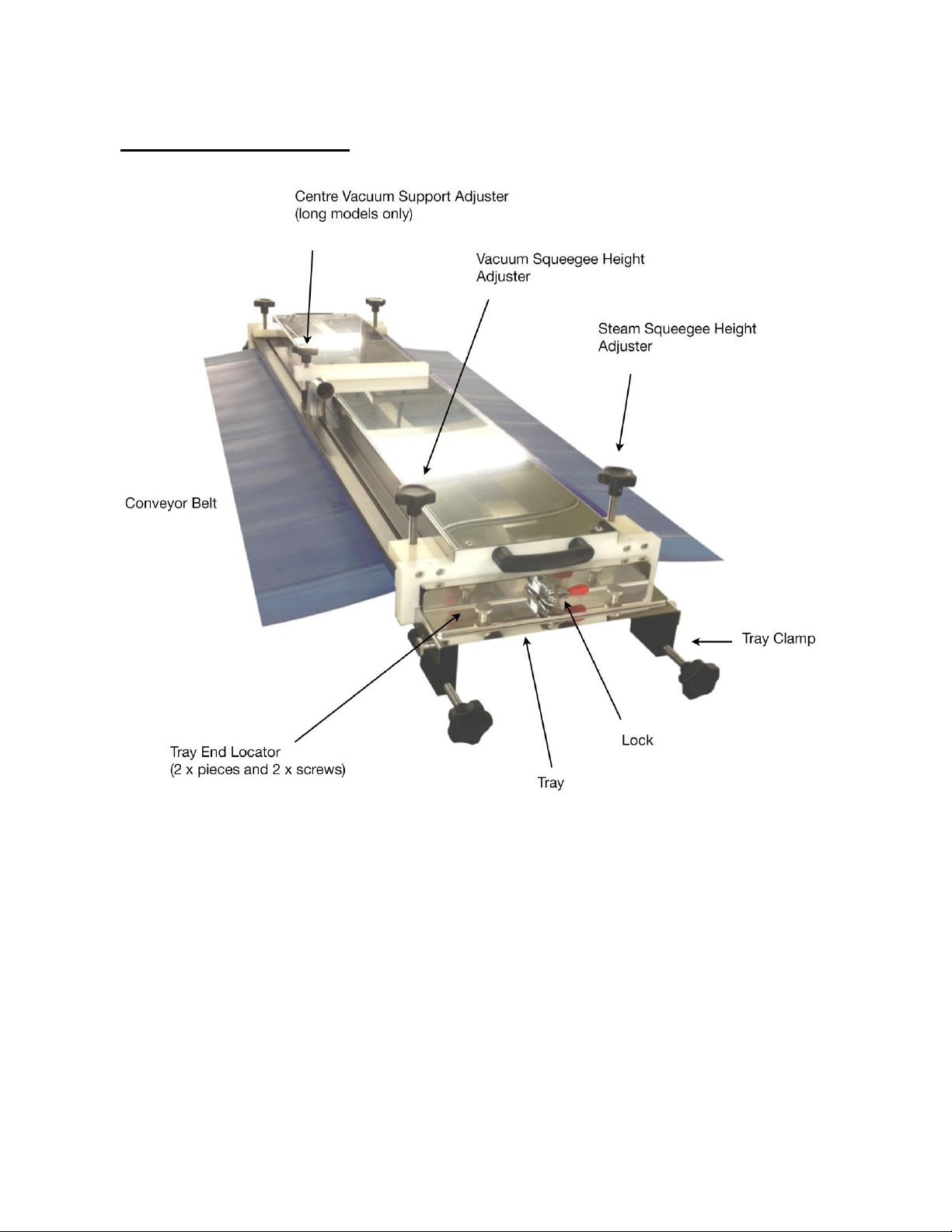

The 93-ACC-BRUSHLESS system is a product designed to clean flat continuous

belts. The system makes use of steam and vacuum to remove debris from the food

contact surfaces of the belt. The system envelopes the total belt, which means that the

edges of the belt are also cleaned, a previously neglected part of belt cleaning and an

area that can otherwise present hygiene problems.

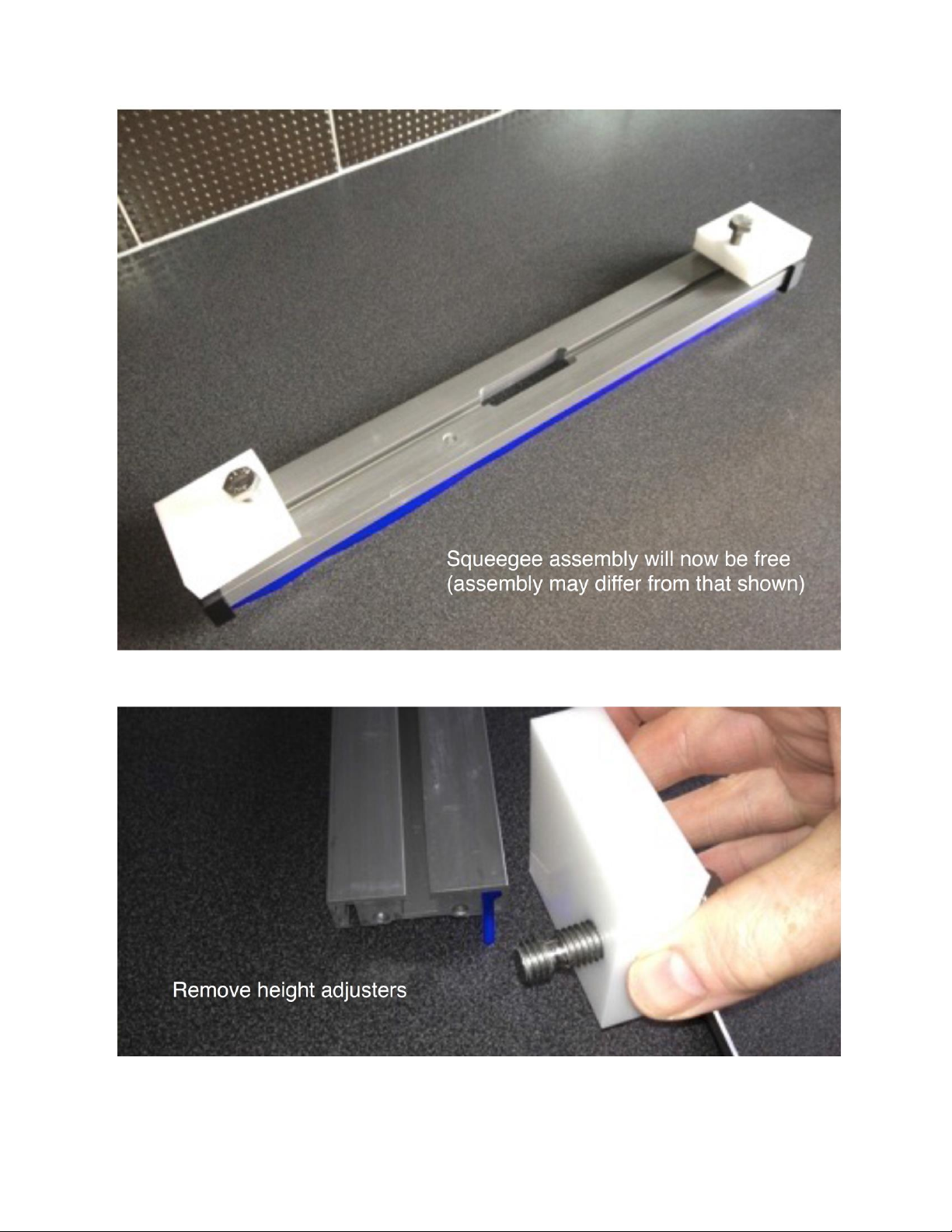

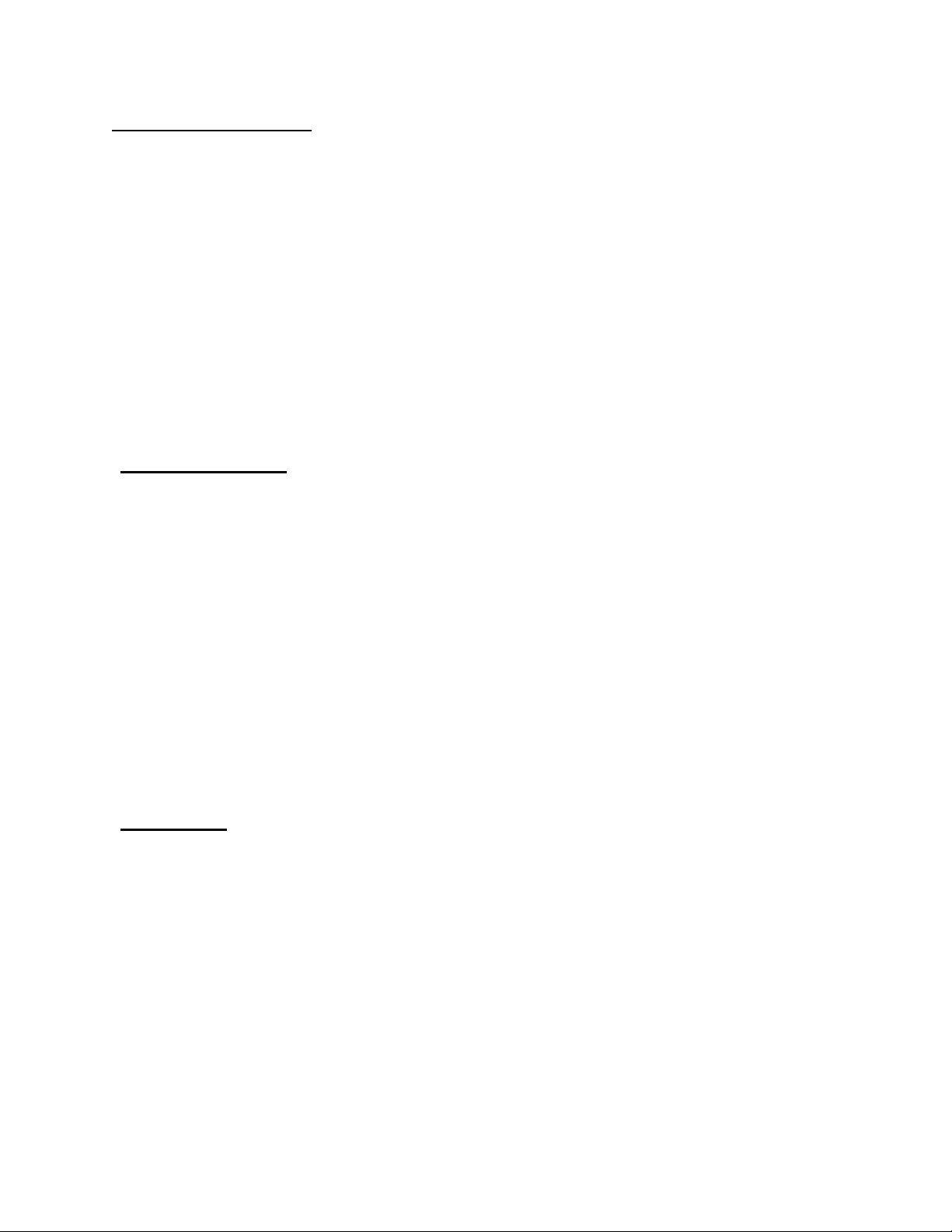

Vacuum is applied through a full width squeegee assembly to the food contact

side of the belt. This vacuum lifts the emulsified debris off the belt, drying the belt in the

process. Vacuum is applied using an industrial vacuum unit that captures the debris in a

tank. The vacuum unit is a separate device, and various models of varying power and

volume are available should this be required.