DURING USE

• Beware of high winds in exposed, gusty or medium breeze conditions.

We recommend that in wind speeds over 7.7 metres per second (27

k.p.h.), cease working on the scaold. If the wind becomes strong and is

expected to reach 11.3 metres per second (40 k.p.h.), tie the scaold to a

rigid structure. If the wind is likely to reach gale force of over 18 metres per

second (60 k.p.h.), the scaold should be dismantled.

• Debris netting or plastic sheeting should not be xed to the scaold

without consulting your local distributor.

• Do not abuse equipment. Damaged or incorrect components should never

be used.

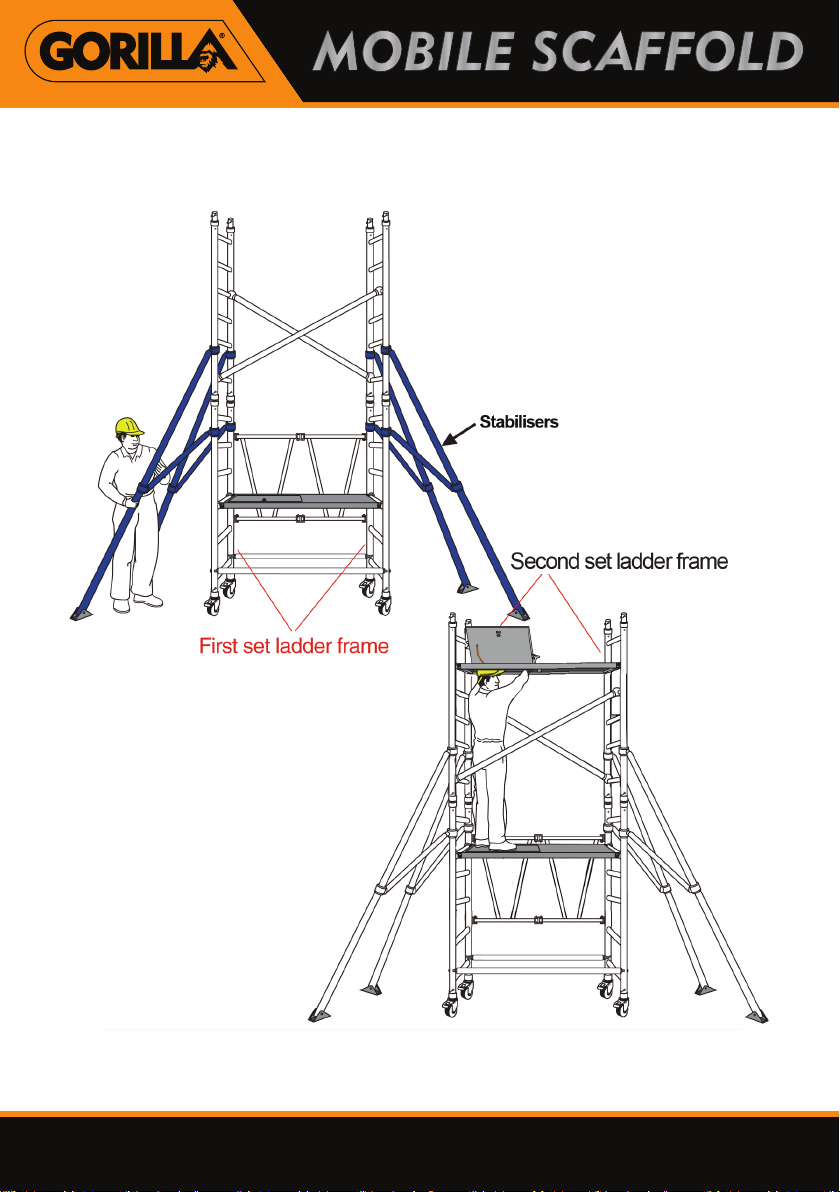

• Raising and lowering components, tools, and/or materials by rope should

be conducted within the scaolding base. Ensure that the safe working

load of the supporting decks and the scaolding structure is not exceeded.

• The assembled scaolding is a working platform and should not be used

as a means of access to other structures.

• This Mobile Scaold is not designed to be suspended – please refer to

your supplier for advice

• Beware of horizontal forces (e.g. power tools) which could generate

instability. Maximum horizontal force 20kg.

BEAUFORT WIND SCALE

FORCE WIND DESCRIPTION SPEED IN KPH GENERAL EFFECT

4 Moderate 20-29 Small branches move. Dust,

leaves & paper raised.

5 Fresh Breeze 30-39 Small trees sway.

6 Strong Breeze 40-49 Small branches move.

7 Moderate Gale 50-59 Telephone wires whistle.

8Gale Force 60-69 Twigs & small branches broken

from trees. Walking is dicult.

Beware of open ended buildings which can cause funneling eect.

4

www.gorillaladders.co.nz