Table

of Contents

Technical

Data

2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco

Phone Number

2.

. . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Meter 8.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Strainer 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electronic Meter 9.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

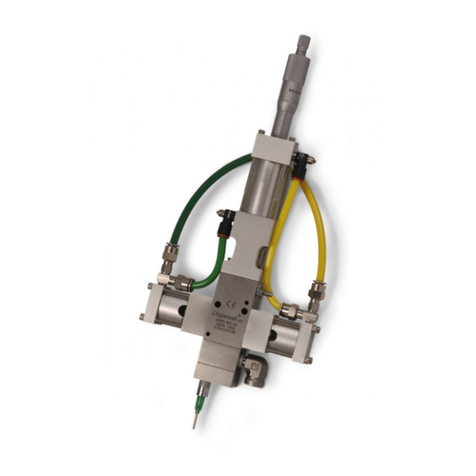

Dispense

V

alve 10.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts

Lists and Drawings

Valve 10.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unmetered

Dispense V

alves 11.

. . . . . . . . . . . . . . . . .

Mechanical

Metered Dispense V

alves 12.

. . . . . . . . .

Metered

In-Line Dispense V

alves 13.

. . . . . . . . . . . . .

Electronic Meter 14.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco

W

arranty 16.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco

Phone

Number

TO

PLACE AN ORDER

, contact your Graco distrib

-

utor

, or call this number to identify the distributor

closest to you:

1–800–367–4023 T

oll Free

Technical

Data

Electronic Meter

Flow

range*

0.12 to 12.0 gpm

.

. . . . . . . . . . . . . . . . . . . .

(0.456

to 45.6 lpm)

Maximum operating pressure

1500 psi (103 bar)

.

. . . .

Weight (bare meter)

1.9 lb (0.95 kg)

.

. . . . . . . . . . . . . . .

Units

of measurement

Factory-set in quarts.

.

. . . . . . . .

Display

shows quantity in 0.01 increments

up to 199.99 gallons, quarts, or pints.

T

otalizes in gallons or liters up to 19,999 units.

Inlet and outlet

1/2 npt, non-directional flow

.

. . . . . . . . .

Operating temperature range –4

F to 130

F.

. . . . . .

(–20

C to 55

C)

Storage temperature range

–40

F to 140

F.

. . . . . . .

(–40

C to 60

C)

Battery specifications

Rated discharge current

100 microamps

.

. . . . . . . . .

Rated

capacity

1.0 amp hour

.

. . . . . . . . . . . . . . . . . . . .

Maximum

continuous discharge

current

1.0 milliamp

.

. . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted

parts

aluminum, nickel, bronze,

.

. . . . . . . . . . . . .

stainless

steel #304,

cast ALNICO 8, nitrile rubber

Mechanical Meter

Flow

range*

0.4 to 4 gpm (1.5 to 15 lpm)

.

. . . . . . . . . . .

Maximum

operating pressure

1000 psi (70 bar)

.

. . . . .

Maximum

operating temperature

150F (70

C)

.

. . . .

Accuracy +/–

0.65%

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inlet

and outlet

1/2 npt(f).

. . . . . . . . . . . . . . . . . . . . . . . . .

Weight 2.1

lbs (0.945 kg)

.

. . . . . . . . . . . . . . . . . . . . . . . . .

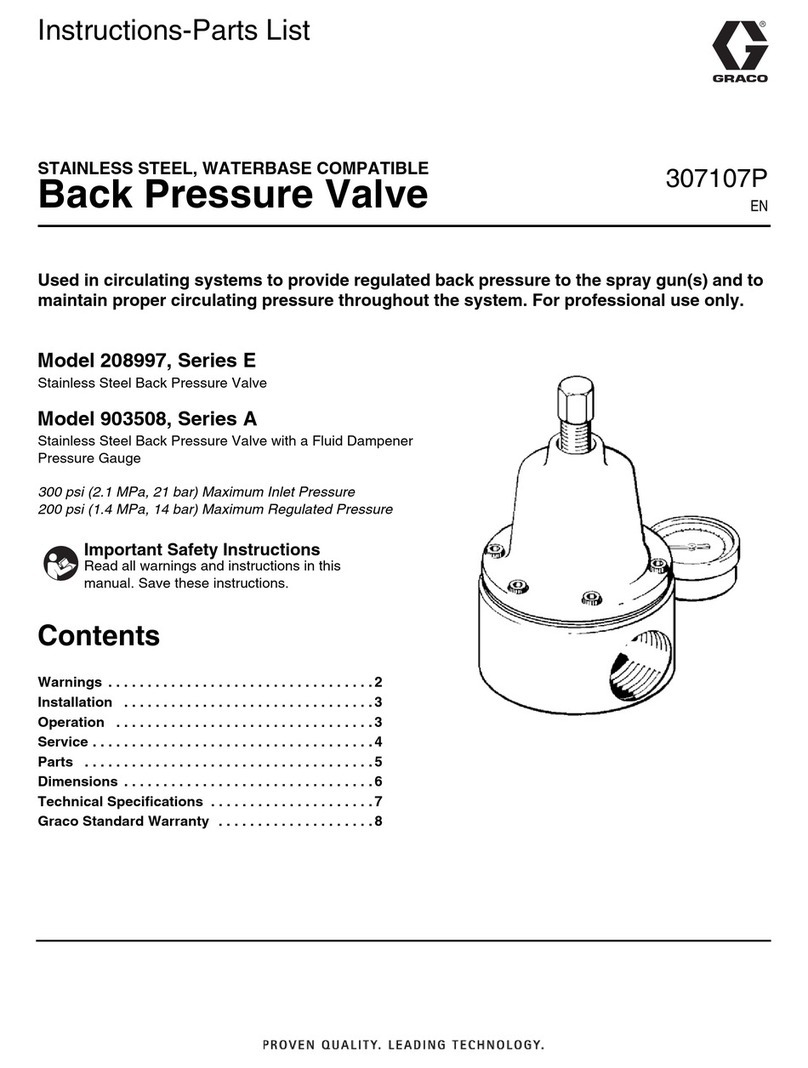

Dispense

V

alve

Recommended

maximum flow*

5.0 gpm

.

. . . . . . . . . . .

(19 lpm)

under normal operating conditions

Maximum operating pressure

1500 psi (103 bar)

.

. . . .

Weight

(without meter)

0.4 lb (0.18 kg)

.

. . . . . . . . . . . . .

Inlet

and outlet

1/2 npt

.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted

parts

aluminum, carbon steel,

.

. . . . . . . . . . . . . .

music

wire, polyurethane,

stainless steel, nitrile rubber

*

Tested

in No. 10

motor oil. Flow rates vary with fluid

pressure

and viscosity

.