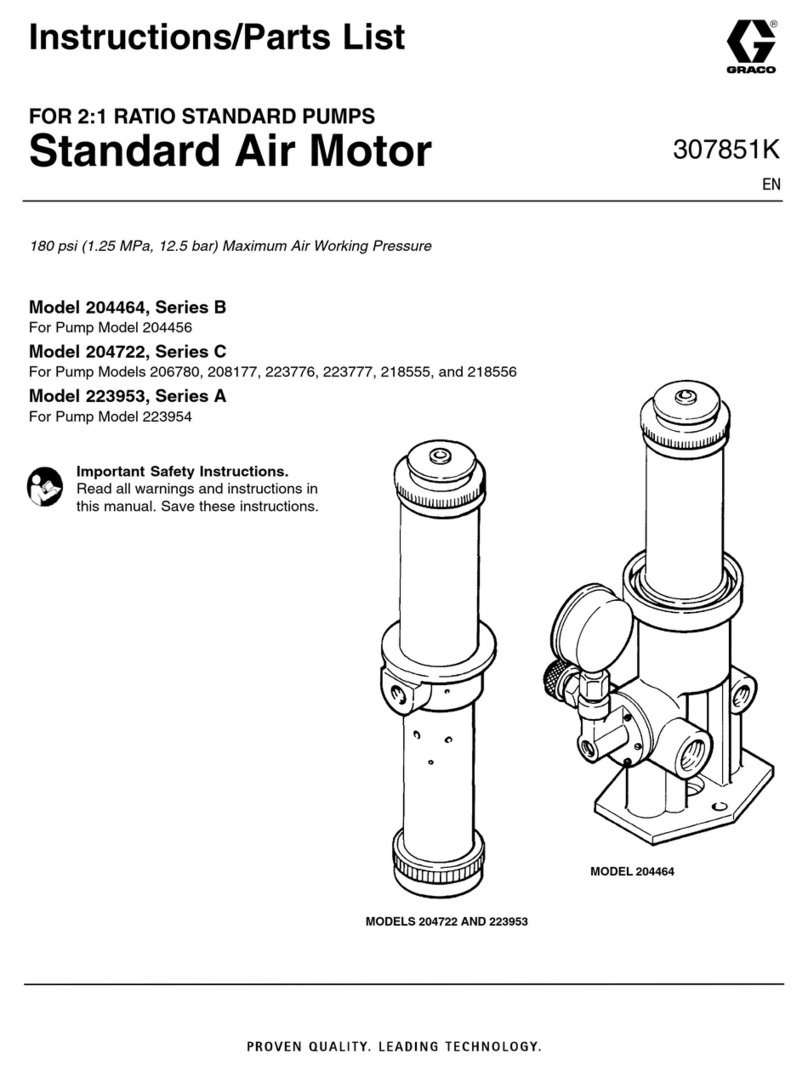

Installation

For the recommended air supply system installation,

see Instruction Manual 307–375.

The following are additional recommendation for

Maximum Noise Reduction.

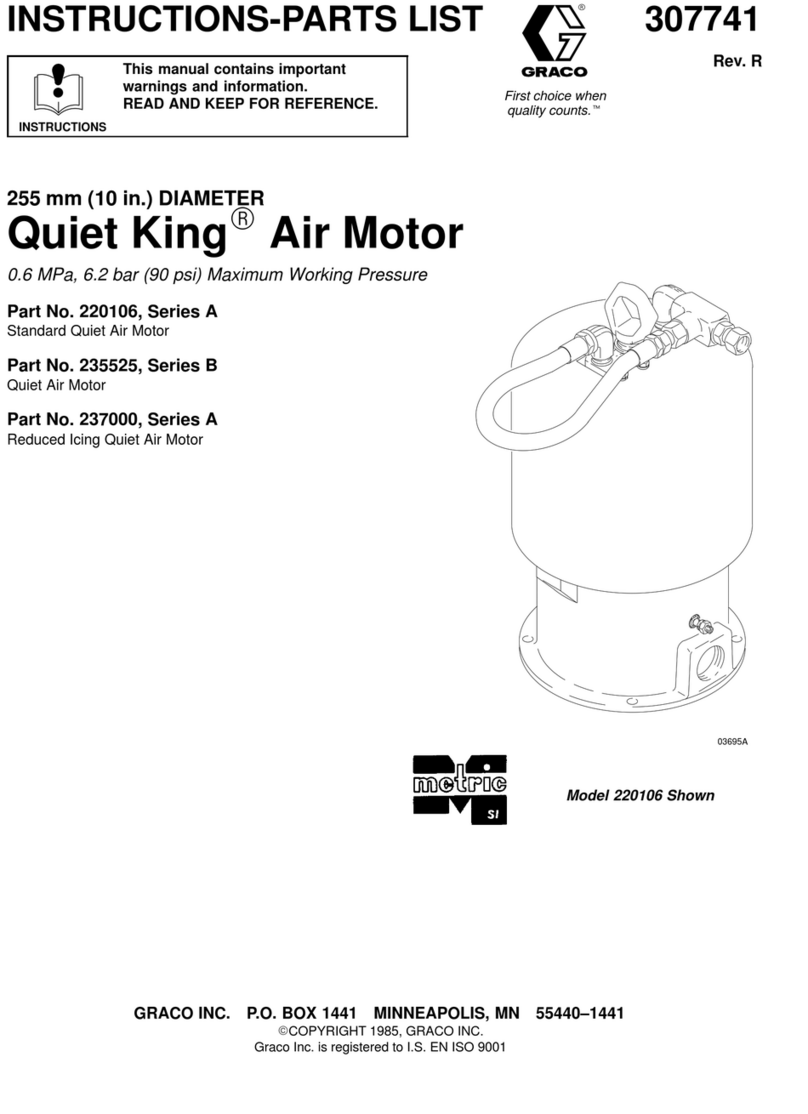

See Fig. 2. The air line should be connected to the

air motor inlet (S) with a grounded flexible hose.

Also, use a flexible fluid outlet and suction hoses.

Where possible, avoid using solid plumbing, which

carries noise vibrations.

Mount the air motor on resilient rubber pads, rather

than sheet metal.

Determine the minimum air inlet pressure and

pump cycle rate necessary to achieve the desired

spray/dispensing results, or minimum fluid pressure

and flow

. This will result in less system wear and

less overall noise.

Air Motor Icing

Moisture

in the compressed air can collect in the air

motor and freeze, causing the motor to stall. This is

called icing. If icing occurs, shut of

f the air supply and

allow the ice to thaw

.

Model 237–001 Reduced Icing Air Motor allows you to

divert a stream of air over the air valves. This flow of

warm air minimizes water collecting and freezing. The

amount of air is adjustable with a needle valve (88, see

the parts drawing on page 16).

T

o minimize icing, reduce the moisture in your com

-

pressed air supply by using an air dryer or a filter

which traps water

.

The main air line should slope slightly downward so

water will collect at the end of the line, where it can be

drained. Additionally

, plumb each drop line from the top

of the main air line. Install an automatic drain or a drain

valve at the bottom of each drop.

For additional assistance in designing your system,

contact your Graco distributor

.

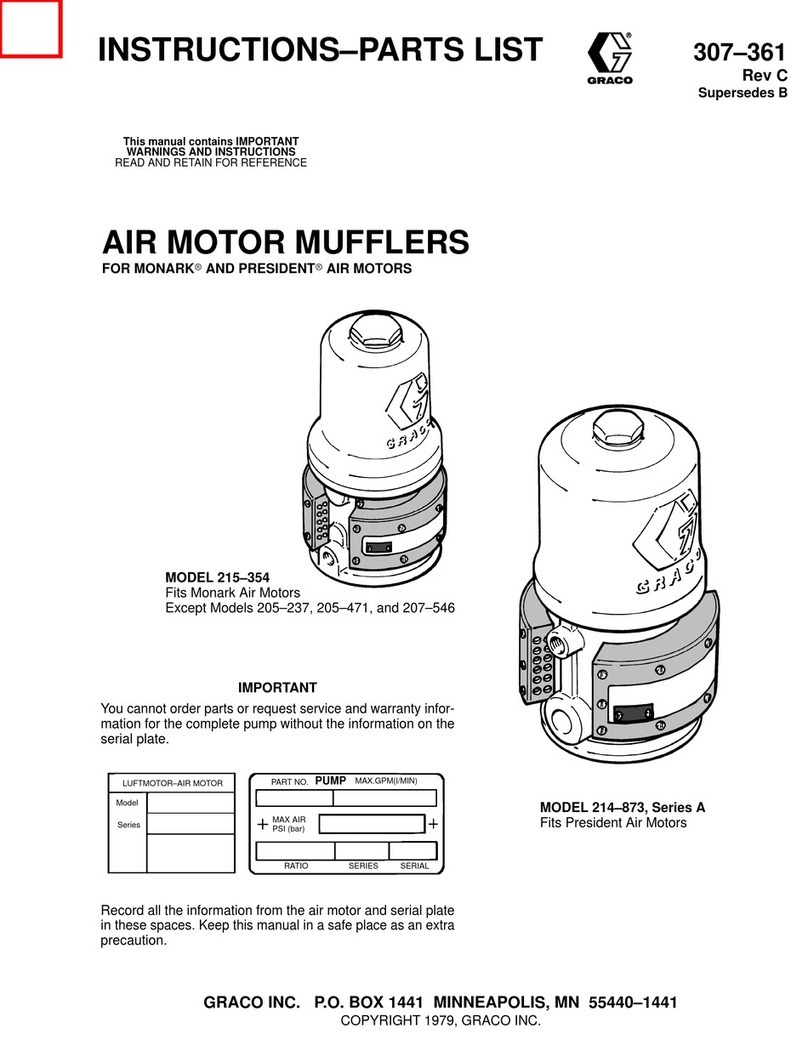

Auxiliary Air Exhaust (Model 215–255)

An

auxiliary air exhaust line may be connected to

Model 215–255, for use in a header system. Remove

the pipe plug (15, see the parts drawing) from the 1”

npt(f) auxiliary air exhaust port (L) at the top of the

motor

. Connect a 1” npt(m) exhaust

hose (M) to this port. The exhaust port must slope

downward, and the exhaust manifold (N) connection

must be lower than the base of the motor (P), to

prevent moisture from accumulating in the line and

draining back into the motor

. See Fig. 2.

Plug the 17 air exhaust holes (R) in the air motor

cylinder with size 3.5 x 1.3, 13 mm long self-tapping

screws.

02958

Fig. 2

1

3

2

Must

slope downward from motor to exhaust manifold.

Exhaust manifold must be lower than base of motor

.

Plug exhaust holes when using auxiliary air exhaust.

KEY

L

Auxiliary Air Exhaust Port

M

1” npt(m) Air Exhaust Hose

N

Exhaust Manifold

P

Motor Base

R

Location of Air Exhaust Holes

S

Main Air Inlet

L

M

M

N

P

R

S

1

1

2

3

Model 215–255 Shown