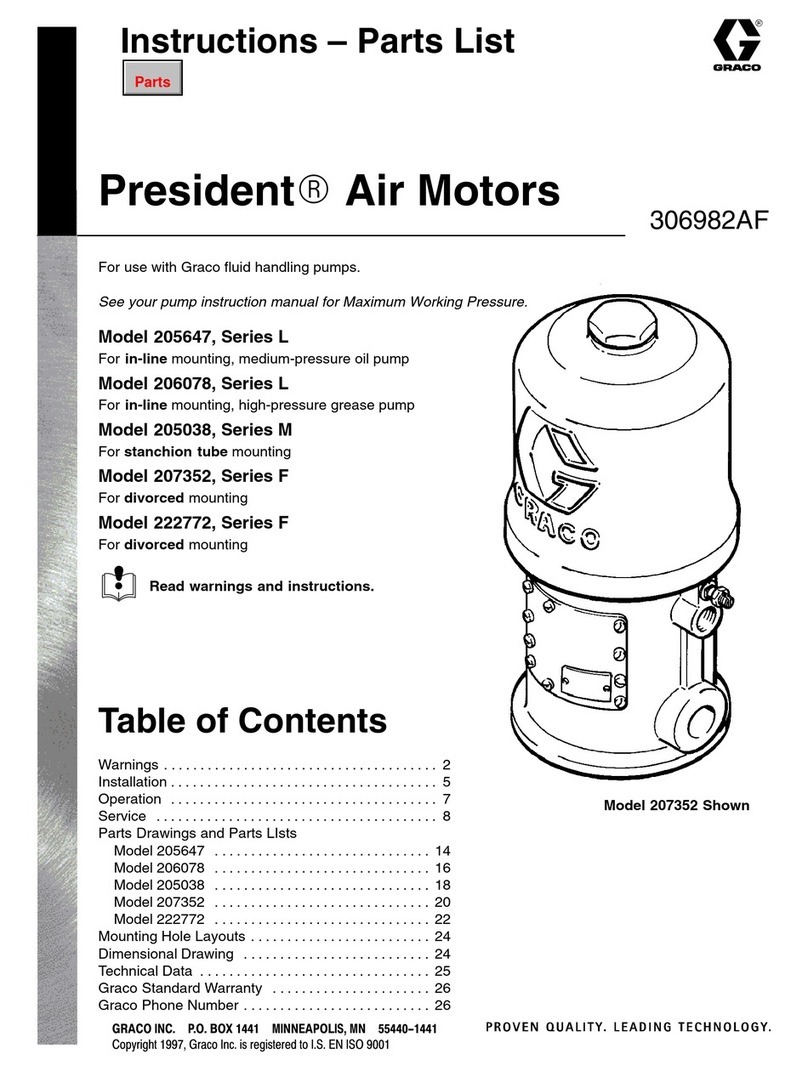

Table

of Contents

Warnings 2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor

Parts Drawing

16.

. . . . . . . . . . . . . . . . . . . . . . . . . .

Motor

Parts List

17.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stroke

Adjuster Parts Drawing and List

18.

. . . . . . . . . .

Dimensions 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor

Mounting Diagram

19.

. . . . . . . . . . . . . . . . . . . . . .

Technical

Data

19.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump

V

ariation Chart

20.

. . . . . . . . . . . . . . . . . . . . . . . . .

Adjust-A-Stroke

Pump Specification

21.

. . . . . . . . . . . .

Warranty 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco

Phone Number

24.

. . . . . . . . . . . . . . . . . . . . . . . . .

Symbols

Warning Symbol

WARNING

This

symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This

symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

WARNING

EQUIPMENT MISUSE HAZARD

Equipment

misuse can cause the equipment to rupture or malfunction and result in serious injury

.

D

This equipment is for professional use only

.

D

Read all instruction manuals, tags, and labels before operating the equipment.

D

Use the equipment only for its intended purpose. If you are unsure about usage, call your Graco

distributor.

D

Do not alter or modify this equipment.

D

Check equipment daily

. Repair or replace worn or damaged parts immediately

.

D

Do not exceed the maximum working pressure stated for your equipment. Do not exceed the

maximum working pressure of the lowest rated component in your system.

D

Do not lift pressurized equipment.

D

Handle hoses carefully

. Do not pull on hoses to move equipment.

D

Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 66

_

C (150

_

F) or below –40

_

C (–40

_F).

DW

ear hearing protection when operating this equipment.

D

Comply with all applicable local, state, and national fire, electrical, and safety regulations.