4 308–598

Important Phone

Numbers

TO PLACE AN ORDER

, contact your Graco distribu-

tor, or call this number to identify the distributor closest

to you: 1–800–367–4023 Toll Free

Manual

Change Summary

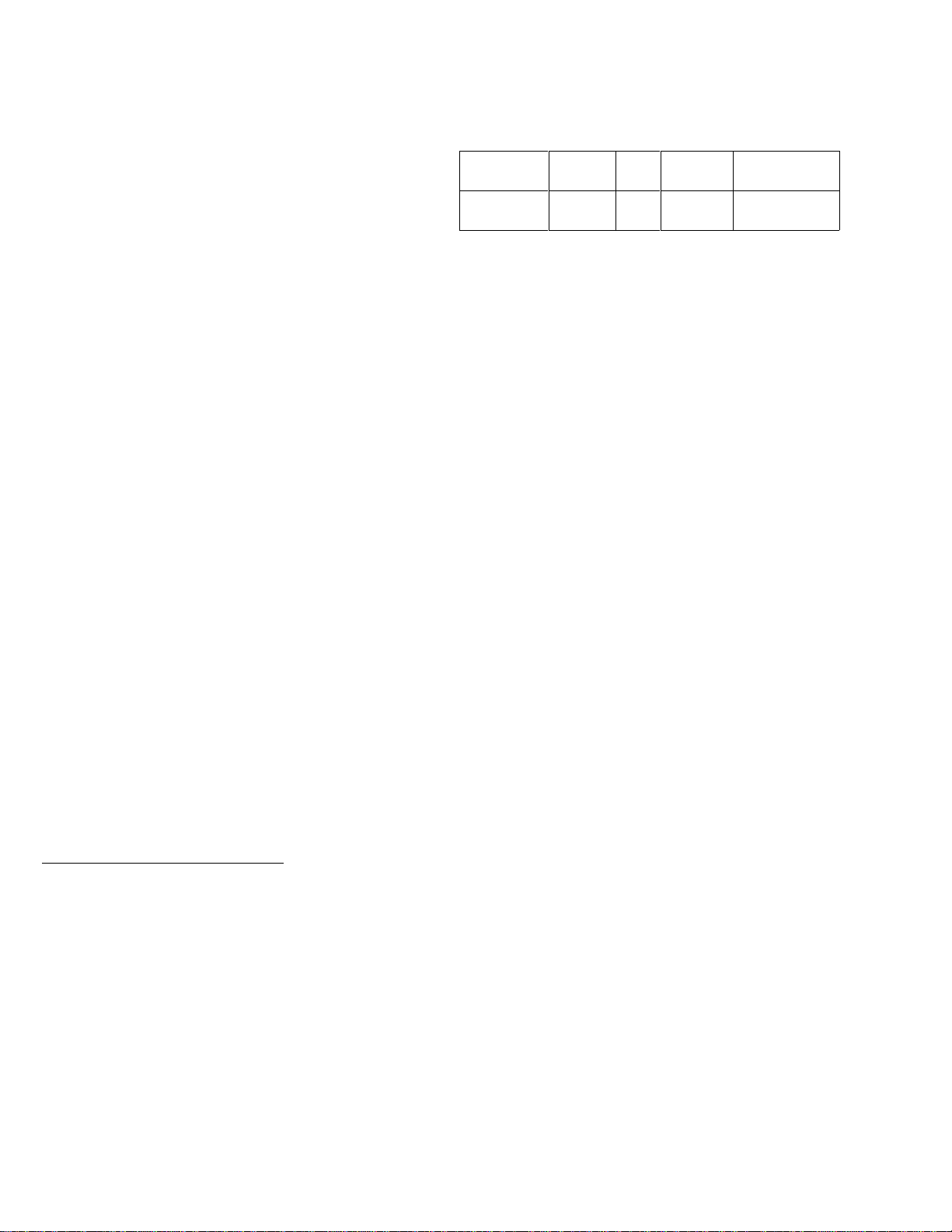

Assembly

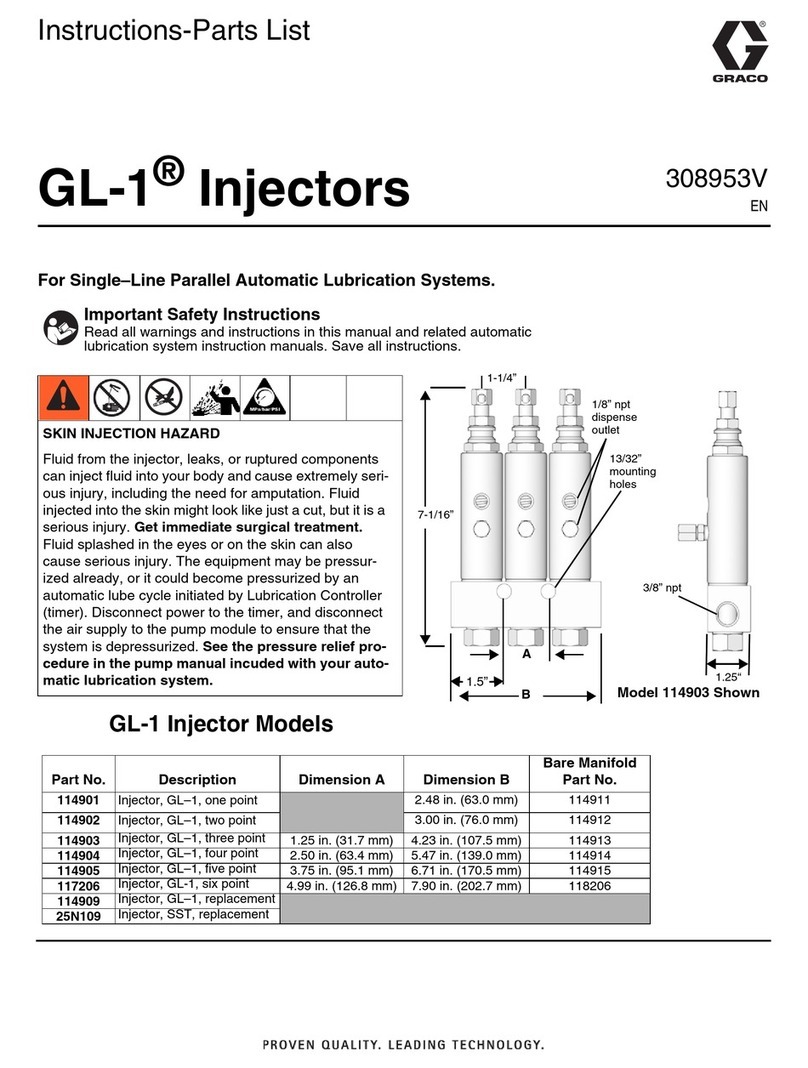

Changed Part

Status Ref.

No. Part No. Name

238–024

Repair Kit ADDED 7 113–894 Clamps

Graco Standard Warranty

GracowarrantsallequipmentmanufacturedbyGracoandbearingitsnametobefreefromdefectsinmaterialandworkmanshiponthe

dateofsalebyanauthorizedGracodistributortotheoriginalpurchaserforuse. Withtheexceptionofanyspecial,extended,orlimited

warrantypublishedbyGraco,Gracowill,foraperiodoftwelvemonthsfromthedateofsale,repairorreplaceanypartoftheequipment

determined by Graco to be defective. This warranty applies only when theequipment is installed,operated and maintainedin accor-

dance with Graco’s written recommendations.

This warranty does not cover, and Graco shallnot beliable forgeneral wearand tear, or anymalfunction, damage or wearcaused by

faultyinstallation,misapplication,abrasion,corrosion,inadequateorimpropermaintenance,negligence,accident,tampering,orsub-

stitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verificationof theclaimed defect. If the claimed defect is verified,Graco willrepair orreplace free of charge any defective parts. The

equipmentwillbereturnedtotheoriginalpurchasertransportationprepaid. Ifinspectionoftheequipmentdoesnotdiscloseanydefect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESSOR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’ssoleobligationandbuyer’ssoleremedyforanybreachofwarrantyshallbeassetforthabove. Thebuyeragreesthatnoother

remedy(including,butnotlimitedto,incidentalorconsequentialdamagesforlostprofits,lostsales,injurytopersonorproperty,orany

otherincidentalorconsequentialloss)shallbeavailable. Anyactionforbreachofwarrantymustbebroughtwithintwo(2)yearsofthe

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

withaccessories,equipment,materialsorcomponentssoldbutnotmanufacturedby Graco. Theseitemssold,butnotmanufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any,of theirmanufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplyingequipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

Thepartiesacknowledgethattheyhaverequiredthatthe presentdocument,aswellasalldocuments,noticesandlegalproceedings

enteredinto,givenorinstitutedpursuantheretoorrelatingdirectlyorindirectlyhereto,bedrawnupinEnglish. Lespartiesreconnais-

sentavoirconvenu que larédactiondu présente documentseraen Anglais, ainsiquetous documents, avisetprocédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Sales Offices: Minneapolis, Detroit

Foreign Offices: Belgium, England, Korea, France, Germany, Hong Kong, Japan

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

PRINTEDIN U.S.A. 308–598 August1995RevisedAugust 1998