2312094K

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

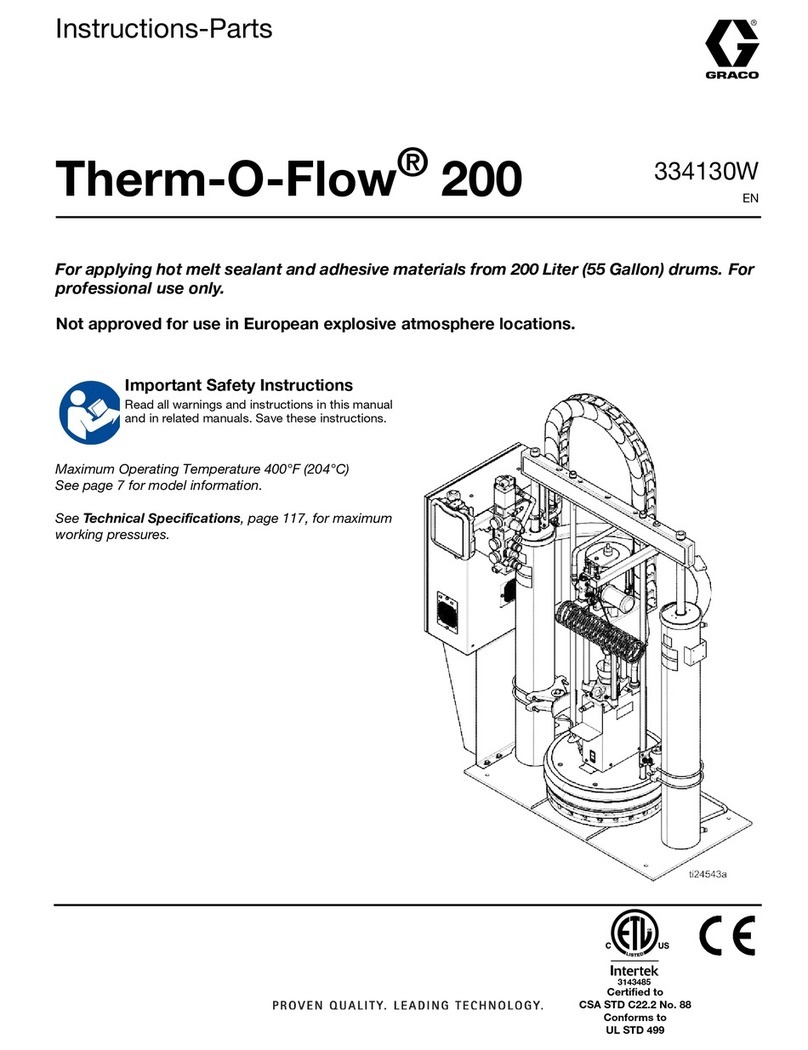

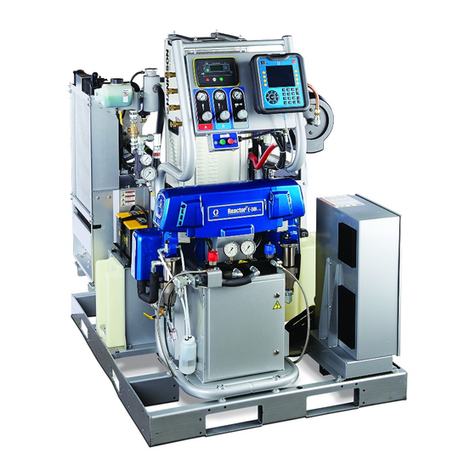

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

How the Therm-O-Flow 20 Works . . . . . . . . . . . . 5

Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Component Identification . . . . . . . . . . . . . . . . . . 6

Power Requirements . . . . . . . . . . . . . . . . . . . . . . 8

Heat Control Zone Selection . . . . . . . . . . . . . . . . 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Location Requirements . . . . . . . . . . . . . . . . . . . . 9

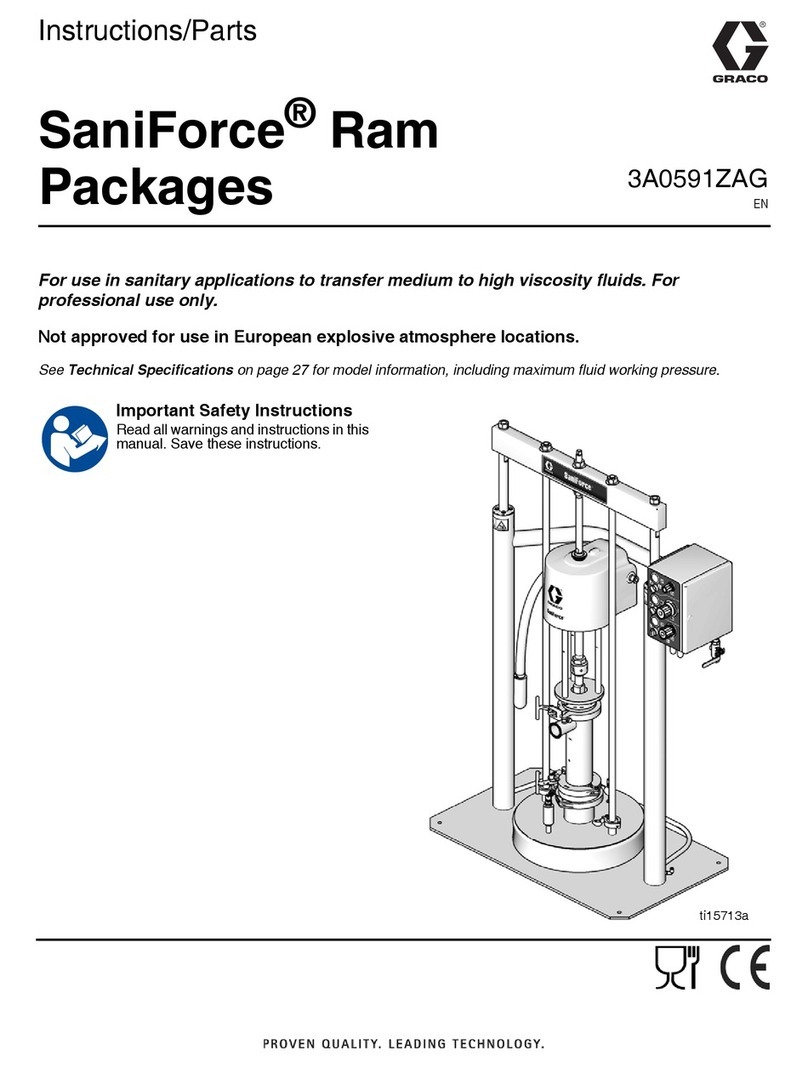

Locate and Install the Ram . . . . . . . . . . . . . . . . . 9

Hose Installation and Care . . . . . . . . . . . . . . . . 10

Mechanical Setup . . . . . . . . . . . . . . . . . . . . . . . 11

Electrically Connect Hoses . . . . . . . . . . . . . . . . 11

Connect the Electrical Control Panel to a Power

Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Check Resistance . . . . . . . . . . . . . . . . . . . . . . . 13

Overview of the Temperature Controller Settings 14

Purging the System . . . . . . . . . . . . . . . . . . . . . . 14

Operator Controls . . . . . . . . . . . . . . . . . . . . . . . . . 15

Main Power Disconnect . . . . . . . . . . . . . . . . . . . 15

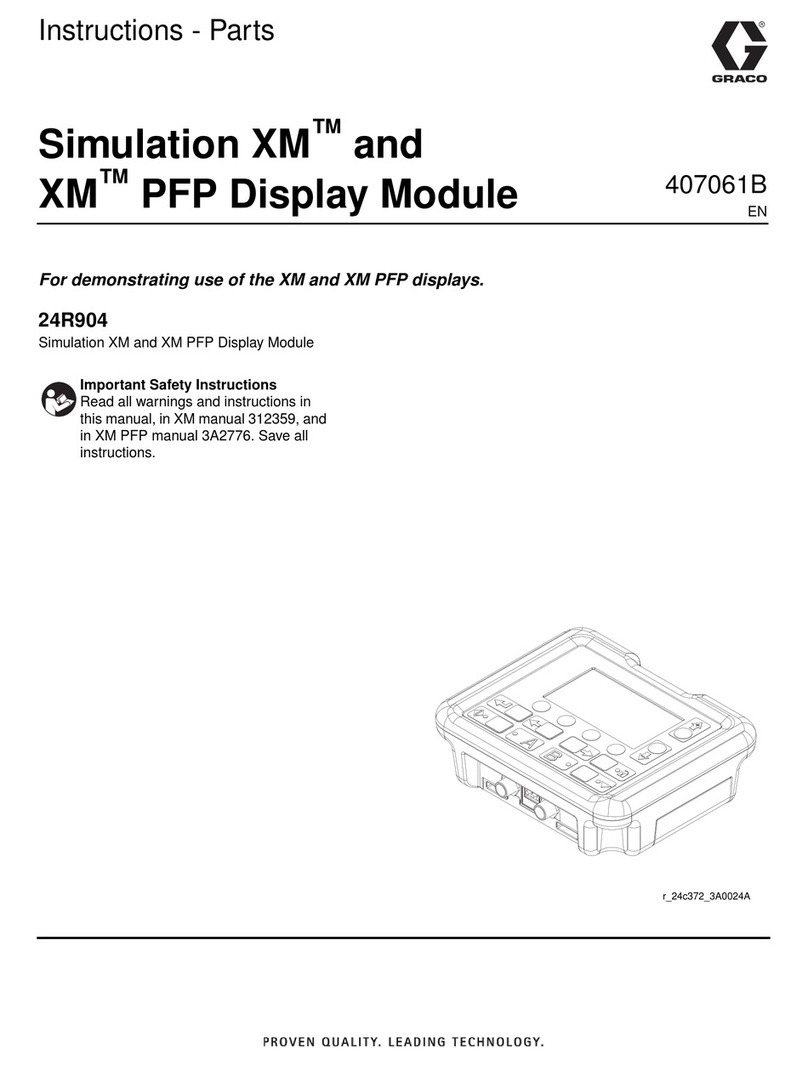

EasyKey Display and Keypad . . . . . . . . . . . . . . 15

LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

EasyKey Display Screens . . . . . . . . . . . . . . . . . . . 17

Power Up Screens . . . . . . . . . . . . . . . . . . . . . . 17

Run Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Purge Before Using Equipment . . . . . . . . . . . . . 23

Set Values on EasyKey . . . . . . . . . . . . . . . . . . . 23

Material Loading . . . . . . . . . . . . . . . . . . . . . . . . 23

System Heat Up . . . . . . . . . . . . . . . . . . . . . . . . 25

Prime System . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Pressure Relief Procedure . . . . . . . . . . . . . . . . 27

Trigger Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Ram Pressure Relief Procedure . . . . . . . . . . . . 28

Pail Changing . . . . . . . . . . . . . . . . . . . . . . . . . . 29

System Shutdown . . . . . . . . . . . . . . . . . . . . . . . 31

Dual Ram Cross-Over Installation . . . . . . . . . . . . 32

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . 32

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Ram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Ground Fault Interrupt . . . . . . . . . . . . . . . . . . . . 33

Power in a Tandem System . . . . . . . . . . . . . . . . 33

Resetting the Ground Fault Interrupt . . . . . . . . . 33

Alarm Troubleshooting . . . . . . . . . . . . . . . . . . . . . 33

Ram Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 35

Pump Troubleshooting . . . . . . . . . . . . . . . . . . . . . 36

Air Motor Troubleshooting . . . . . . . . . . . . . . . . . . 36

Electrical Control Panel Troubleshooting . . . . . . 37

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Ram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Ground Fault interrupt . . . . . . . . . . . . . . . . . . . . 38

Power in a Tandem System . . . . . . . . . . . . . . . . 38

Platen Service . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Air Motor/Pump Removal and Service . . . . . . . 40

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Therm-O-Flow 20 . . . . . . . . . . . . . . . . . . . . . . . 42

Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Platen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Air Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

EasyKey Assembly, Part No. 255224 . . . . . . . . 47

Spare Parts and Kits . . . . . . . . . . . . . . . . . . . . . 48

Electrical Schematics . . . . . . . . . . . . . . . . . . . . . . 49

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Light Tower Kit (253547) . . . . . . . . . . . . . . . . . . 53

Pail Low and Empty Sensor Kit (255233) . . . . . 55

Ethernet Kit (253566) . . . . . . . . . . . . . . . . . . . . 56

EasyKey Modbus / TCP Wiring Diagram . . . . . . 62

Maintenance Call Kit (253548) . . . . . . . . . . . . . 63

Discrete I/O Kit (253567) . . . . . . . . . . . . . . . . . . 65

Swirl Kit, Part No. 253263 . . . . . . . . . . . . . . . . . 67

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 70

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 70