Installation

Motor, Motor,

Motor,Bearing Bearing

BearingHousing, Housing,

Housing,and and

andImpeller Impeller

Impeller

Installation Installation

Installation

Allelectricalwiringmustbedonebyaqualied

electricianandcomplywithalllocalcodesand

regulations.Onlytrainedandqualiedpersonnel

whohavereadandwhounderstandtheinformation

inthismanualshouldinstallthisequipment.

Alwaysmaintainaminimumof1in.(25.4mm)

clearancebetweenrotatingagitatorpartsand

containertopreventsparksfromcontact.

Personalinjuryorequipmentdamagemayresult

fromlifting/fallingheavyequipment.Toavoid

personalinjuryorequipmentdamage:

•Donotliftthedrumcoverandagitatorwithout

properassistance

•Donotwalkorstandbeneatharaisedelevator.

Forbestresults,donotremoveanyprotective

wrappingsfromanyoftheagitatorpartsuntiljust

priortoassemblyandinstallation.Storeallparts

indoors,incleandryair.

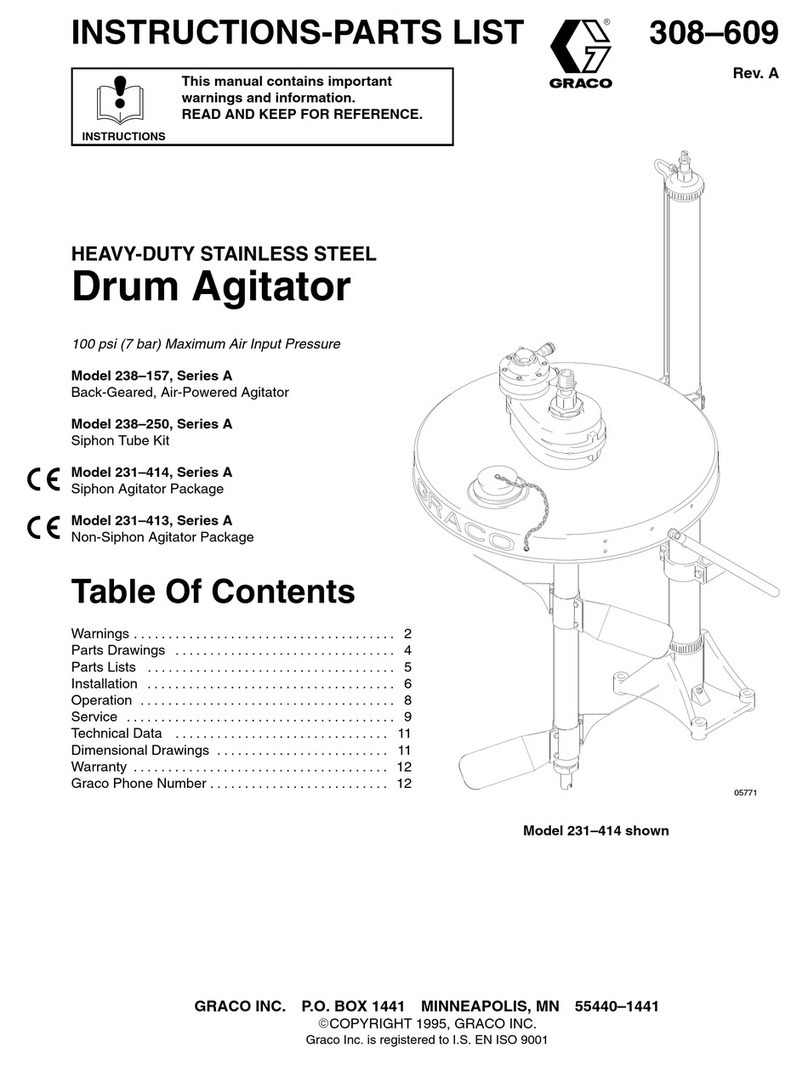

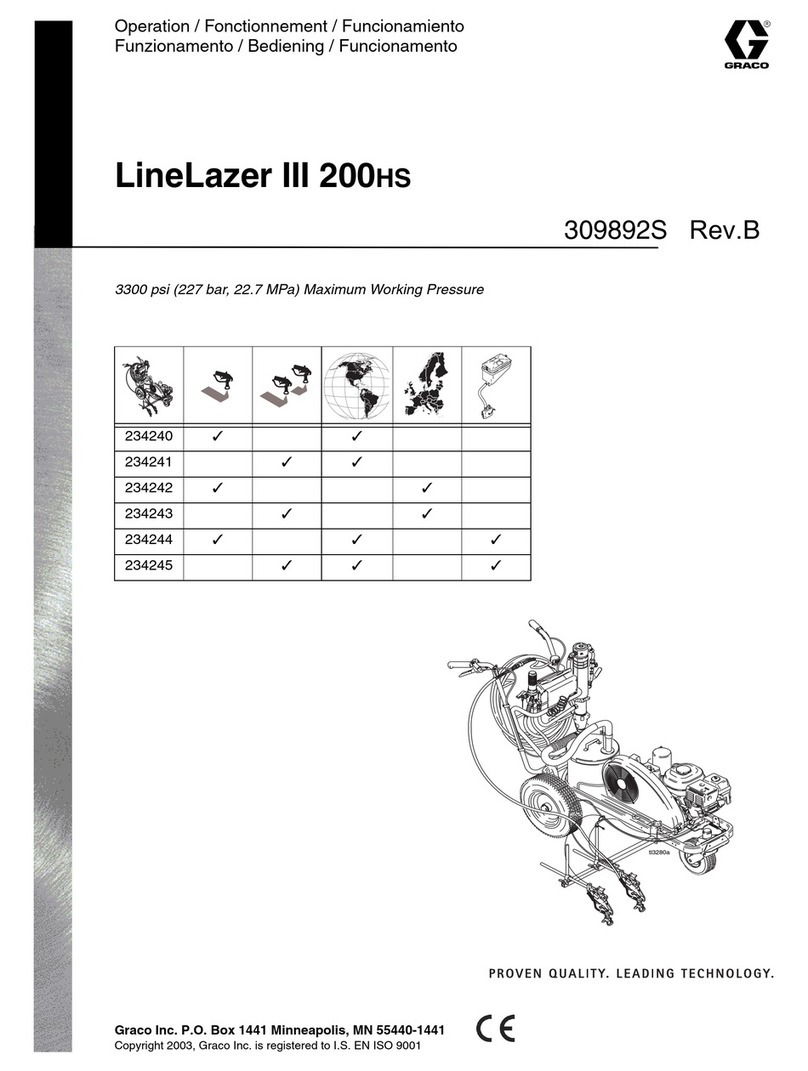

Figure2showstheholesforinstallingagitatoranges

(partnumbers25C454and25C453)tothemounting

surface.Holesrequiredinthemountingsurfaceare:

Shaft Shaft

Shafthole: hole:

hole:1"-2"(2.54cm-5.08cm)

Mounting Mounting

Mountingthe the

theange ange

ange(3 (3

(3methods): methods):

methods):

•(3)holestomounttoGracodrumlidsthathave

mountingsurfaceforback-gearagitatorhousings.

•(4)holesfor3"150#ANSIangepattern(6"

diameterboltcircle).Thispatternisfornew

installations.

•(4)holesformountingtoanexistingGracoLSA

suppliedagitatormountingpattern(6.25"diameter

boltcircle).

Figure2AgitatorMountingHoleDimensions

Motorandbearinghousingweighapproximately50

lbs(22.6kg).Verifythatadequatepersonnelare

availableorasecureliftingdeviceisavailableforuse

inpositioningandinstalling.

NOTE:Eyebolts(26)areshippedloosetobe

attachedforliftingtheagitator.Seeattachment

location(Parts,page13).

1.Installbearinghousing/angeassemblyperthe

following:

a.Forangemount:See

Models25C454and25C463,page13for

partsidentication.Placegasket(20)and

bearinghousing/angeassembly(A)ontank

cover.Installatwashers,mountingbolts,

andnuts(notprovided).Tightensecurely.

b.Forquick-clampangemount:See

Models25C453,25C575,25C464,25C576,

page15forpartsidentication.Place

bearinghousing/angeassembly(A)on

topofquick-clampgasket(notprovided)

andexistingquick-clampangeontank.

Attachwithclamp(notprovided)andtighten

securely.

c.Forpressuretank:SeeModels25C462,

25C470,25C471,25C465,25C472,25C473,

page17forpartsidentication.Placegasket

(21)andbearinghousing/angeassembly

(A)onpressuretankcover.Installand

securewithlockwasher(32)andnut(22).

Tightensecurelytopreventassemblyfrom

rotating.

2.Installtheretainingring(6)inthemachinedslot

intheagitatorshaft(24).

3.Slideshaftthroughthebearinghousing/ange

assemblyfromthetopsideofthebearinghousing

untiltheretainingringrestsontheupperbearing.

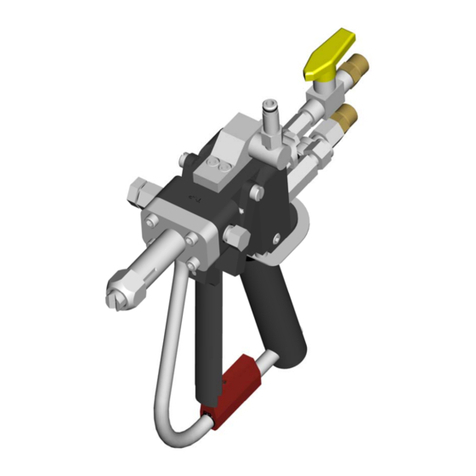

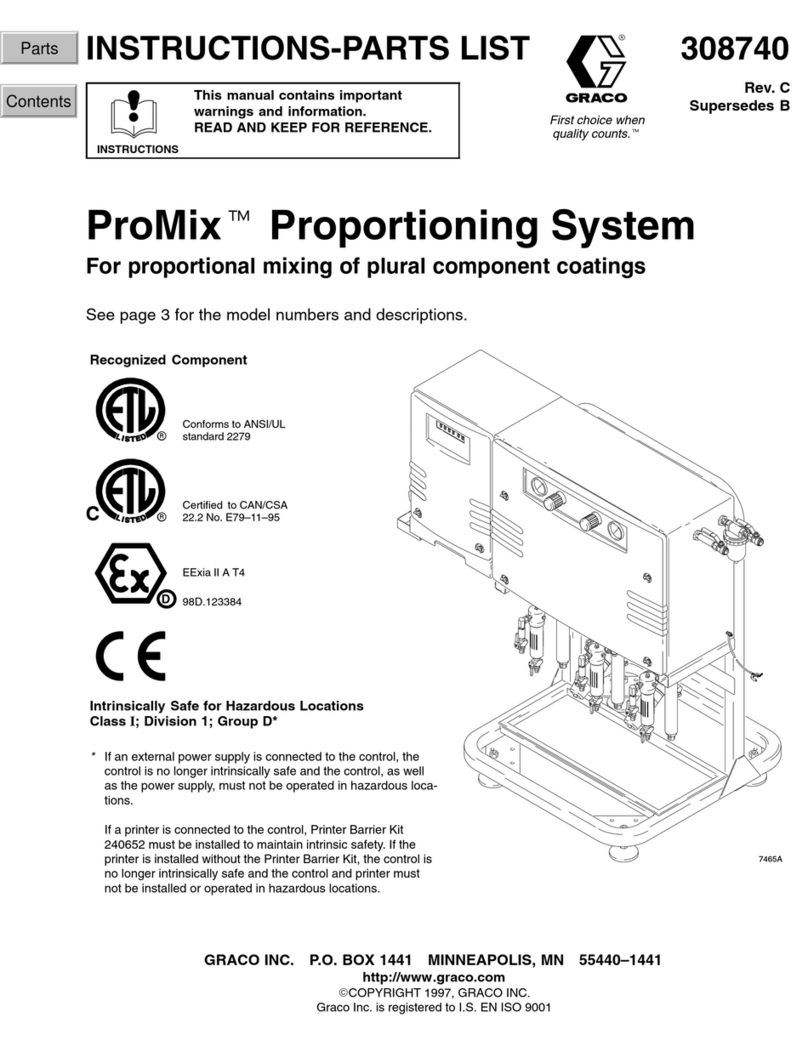

4.Slidetheimpeller(23)(seeFigure3)ontothe

shaft(24)sothebladeispushingmaterialdown

withthebladeturningclockwisewhenviewed

fromabove.Shaftcanbemovedupanddownin

thebearinghousingtoinstalltheimpeller.

5.Positiontheimpelleralongtheshaftasrequired:

Thedistancefromthetankbottomtothelowest

impellerblade(BB)shouldbe1/2to1–1/2times

theimpellerbladediameter(bladediameteris

determinedbymeasuringthedistancefromthe

tipoftheimpellertotheshaftcenter(AA)and

multiplyingbytwo).

Figure3ImpellerInstallation

6.Securetheimpellerbytighteningthesetscrews

(23a).SeeParts,page13.

7.Placecoupling(7)ontoagitatorshaftabovethe

retainingringandtightensetscrew(7a)securely.

8.Placespiderdiskcoupling(8)ontop.

3A4553F7