Air Cap Test Kit for Spray Guns

The purpose of this test kit is to verify atomising air

pressure. This is important to demonstrate compliance to

air quality regulations, as well as to conrm operational

standards. Follow instructions below.

ASSEMBLY

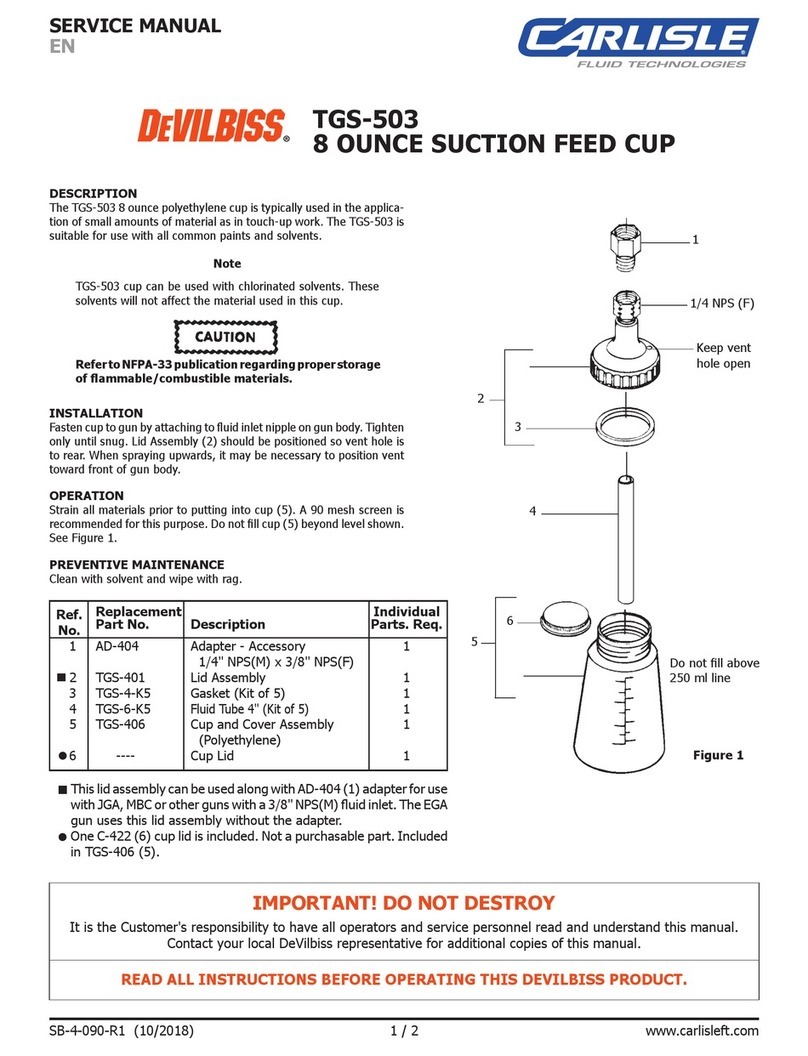

1. Install tting (2) onto gauge (1) and tighten.

2. Remove air cap and retaining ring from spray gun.

3. Install test cap/ring (4) onto gun.

4. Push ends of tubing over barbed ttings on both the test

cap and gauge.

Care must be taken not to allow the test gauge to hang by

the tubing as damage to gauge could occur.

!

CAUTION

Fan air port fitting must be capped with black vinyl cap for

correct pressure measurement.

NOTE

TEST PROCEDURE

1. Position fan adjusting knob on the gun to the position

used for paint being sprayed.

2. Disconnect or empty paint supply. Turn air source on.

3. Hold gauge in up-right position, trigger gun and observe

reading on test gauge.

4. Adjust inlet pressure to obtain desired atomising air

pressure.

5. Remove test air cap/ring and replace with gun air cap

and ring before spraying paint.

In some areas, legislation exists prohibiting the use of

more than 10 PSIG air cap pressure. (There is no advantage

to spraying at more than 10 PSIG.) When atomising air

pressure is set at 10 PSIG or less, the fan air pressure will

always be less than 10 PSIG. This can be verified by

pushing the tubing over the fan air port, capping the center

air port and repeating Step 3. Always recheck pressures

after any adjustments to the fan knob.

NOTE

Center Air Port

(Atomising)

Fan Air Port

PARTS LIST

REF.

NO.

REPLACEMENT

PART NO. DESCRIPTION QTY.

1GA-313 Gauge 0–15 PSI 1

2— Barbed Fitting 1

3 — Tubing 1

4—Test Air Cap 1

5 — Black Vinyl Cap 2

TI-1005-R1 (2/2019) 1 / 2 www.carlisleft.com

SERVICE MANUAL

EN