23A4167C

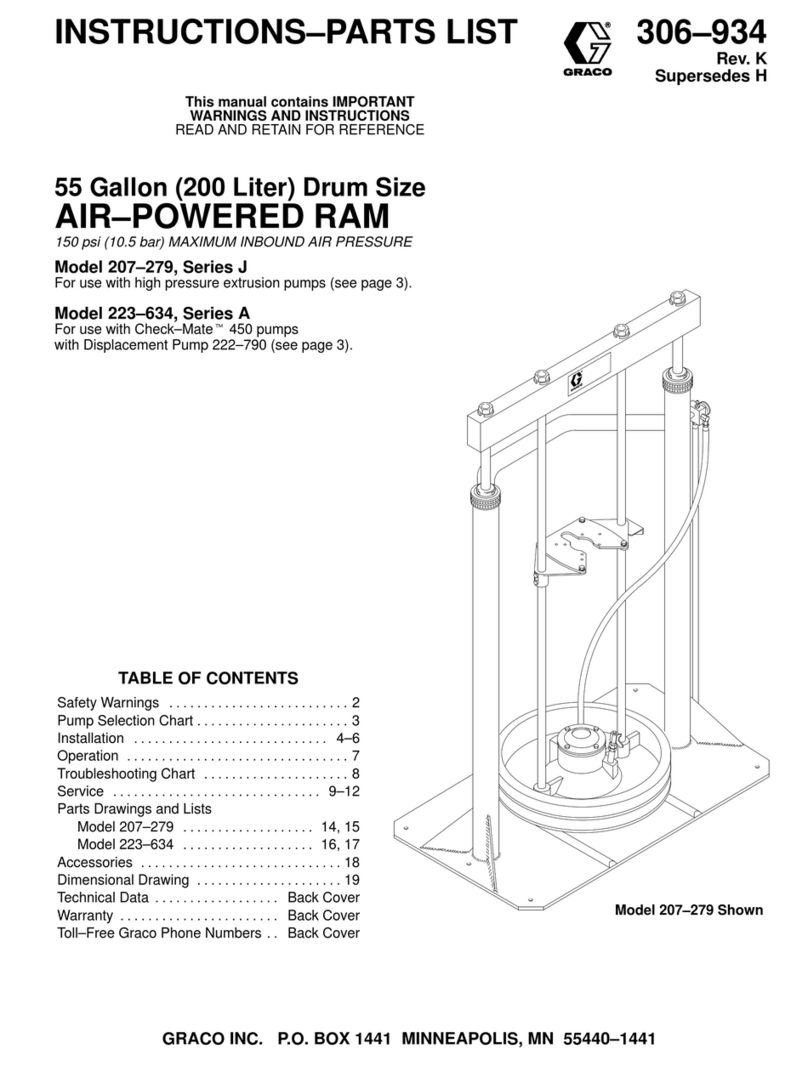

Contents

Models ...................................3

Related Manuals ...........................3

Warnings .................................4

Component Identification ....................6

Geo Blaster Components ..................6

Panel Controls ..........................7

Manual Valves ..........................8

Water Tank Components ..................9

Pressure Relief Procedure ..................10

Operation ................................11

ImportantNote .........................11

Checklist Before Starting .................11

Lifting the System .......................11

Setting Up the Equipment .................12

Refilling the Blast Pot ....................15

Wash Down ............................17

Shutdown .............................18

Troubleshooting ..........................19

Parts ....................................23

GeoBlaster ............................23

Control Panel Interior ....................24

Control Panel Components - upper left .......25

Control Panel Components - lower left .......27

Control Panel Components - lower right ......29

Control Panel Components - upper right ......31

Control Panel Components - rear ...........33

Water Valve and Pressure Relief Valve

Components ........................35

Air Valve Components ...................37

Water Valve and Filter Components .........39

Water Tank and Blast Pot Components ......41

Water Pump Components .................42

Accessories and Kits ......................44

Hose Schematics ..........................46

Tubing ................................46

Air Line Tubing .........................46

Pneumatic Schematic ....................47

Water Tubing ..........................48

Water Tubing Connections ................49

Technical Data ............................ 50

GB400 ................................50

GB600 ................................51

GB1200 ...............................52

Graco Extended Warranty for Geo Blaster

Components ..........................54