Warnings

43A5056B

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclama-

tion point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

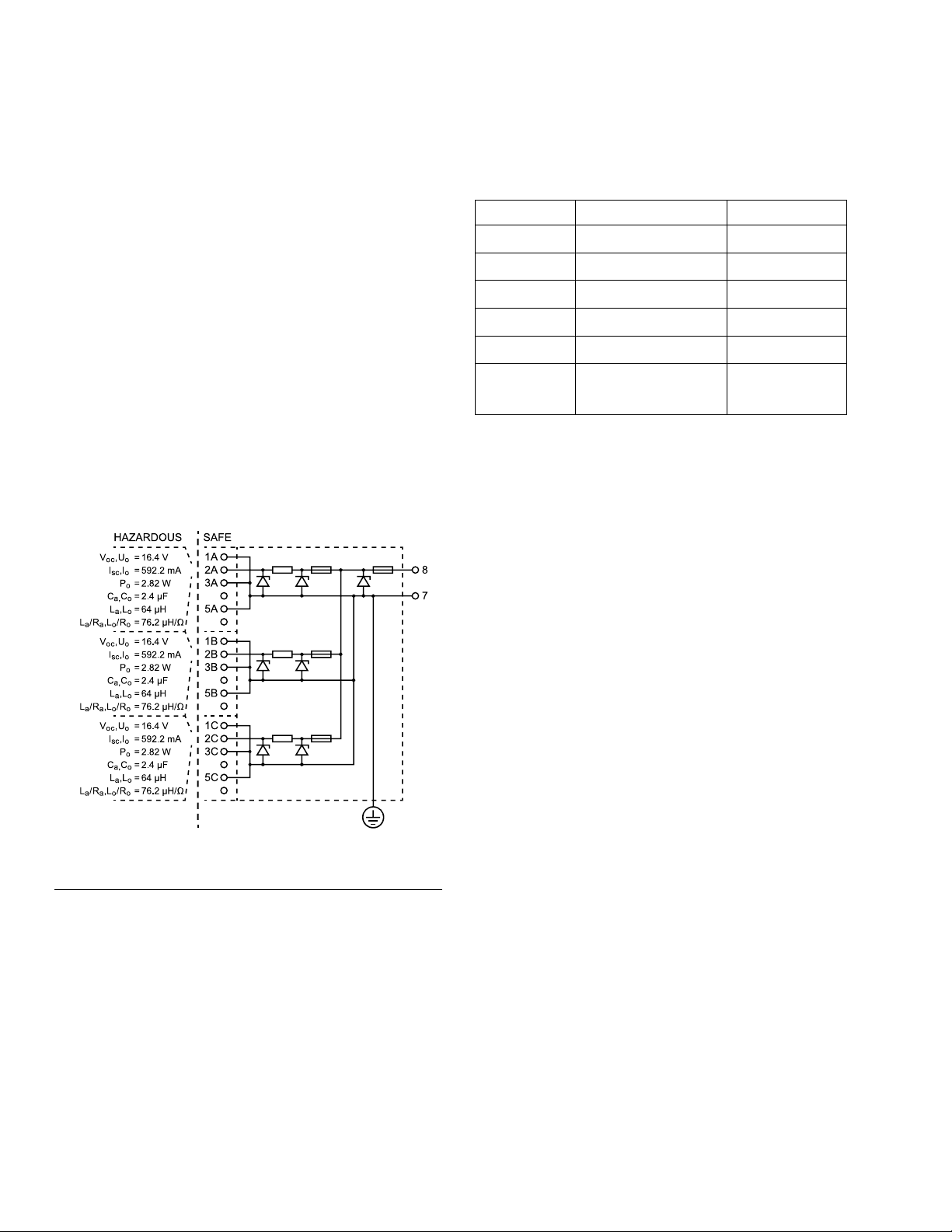

INTRINSIC SAFETY

Intrinsically safe equipment that is installed improperly or connected to non-intrinsically safe equipment

will create a hazardous condition and can cause fire, explosion, or electric shock. Follow local

regulations and the following safety requirements.

• Be sure your installation complies with national, state, and local codes for the installation of electrical

apparatus in a Class I, Division 1, Group D, or Zone 0, or 1, Group IIA (as applicable) Hazardous Loca-

tion, including all of the local safety fire codes. For the United States, this includes NFPA 33, NEC 500

and 516, and OSHA 1910.107.

• Equipment that comes in contact with the G-Barrier’s intrinsically safe terminals must be rated for

Intrinsic Safety. This includes DC voltage meters, ohmmeters, cables, and connections.

• Do not install the G-Barrier, which is non-intrinsically safe, in a hazardous area, as defined in Article

500 of the National Electrical Code (USA) or your local electrical code.

• The G-Barrier must be properly grounded to be effective. For proper grounding, use the ground wire

provided (or a 12-gauge minimum ground wire), and the G-Barrier’s ground must be within 1 ohm of

true earth ground. For more information, see Installation.

• Do not operate the G-Barrier module with the cover removed.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and regu-

lations.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.