- 3 -

Intended Purpose

The RMM 251 tyre-changer is intended to be used for the mounting and demounting of truck, bus,

agricultural vehicle and earthmover tyres.

The GRANIT RMM 251 model is CE-certified.

This machine may only be used for the purpose for which it is designed by the manufacturer.

Any damage caused by improper operation is not covered by the warranty.

General Safety Instructions

Only properly trained and qualified personnel are allowed to use this machine.

Any modification and conversion work on the machine that has not been authorized by the manufacturer,

can cause significant damage to property as well as personal injury in which case the

manufacturer/supplier will not incur any liability.

The machine must only be used according to its intended use and prescribed handling.

Before and during mounting, it is mandatory to ensure that the tyre and rim fit together and are compatible

with each other (matching sizes, e.g. the diameter in mm or inch, etc.).

If disturbances occur during operation or during the work process, the power supplies of the machine

must be switched off before any technical intervention.

All electrical connection or clamping may only be carried out by a qualified electrician, taking into account

the requirements of the national electricians‘ authority and/or the relevant energy supply company.

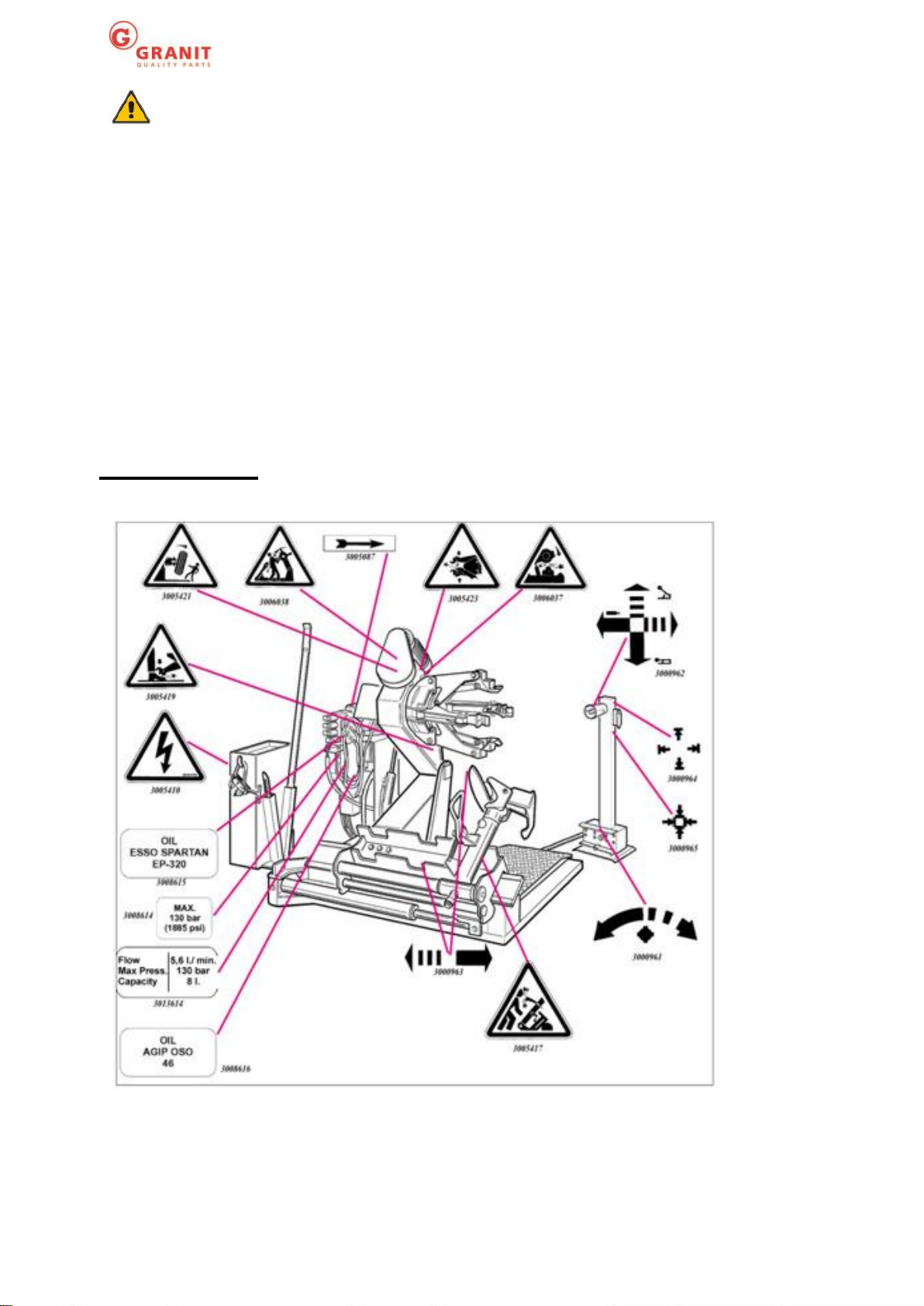

Since there is always a non-foreseeable residual risk when working with technical work equipment,

various self-explanatory warnings signs (triangle yellow/black) are affixed to the tyre-changer.

These warnings signal to the user a possible residual danger and should cause him to be particularly

mindful in order to avoid accidents at work and/or damage to the product to be worked on, i.e. the tyres

and rims.

The machine is only to be used by professionally skilled personnel who are aware of the safety

regulations.

In general, the operator should eliminate any possible residual risks from the outset through proper and

prudent behavior.