1

10/14/2020

Table of Contents

Introduction ...........................................................................................................................................................2

Specifications .........................................................................................................................................................2

Safety Precautions .................................................................................................................................................3

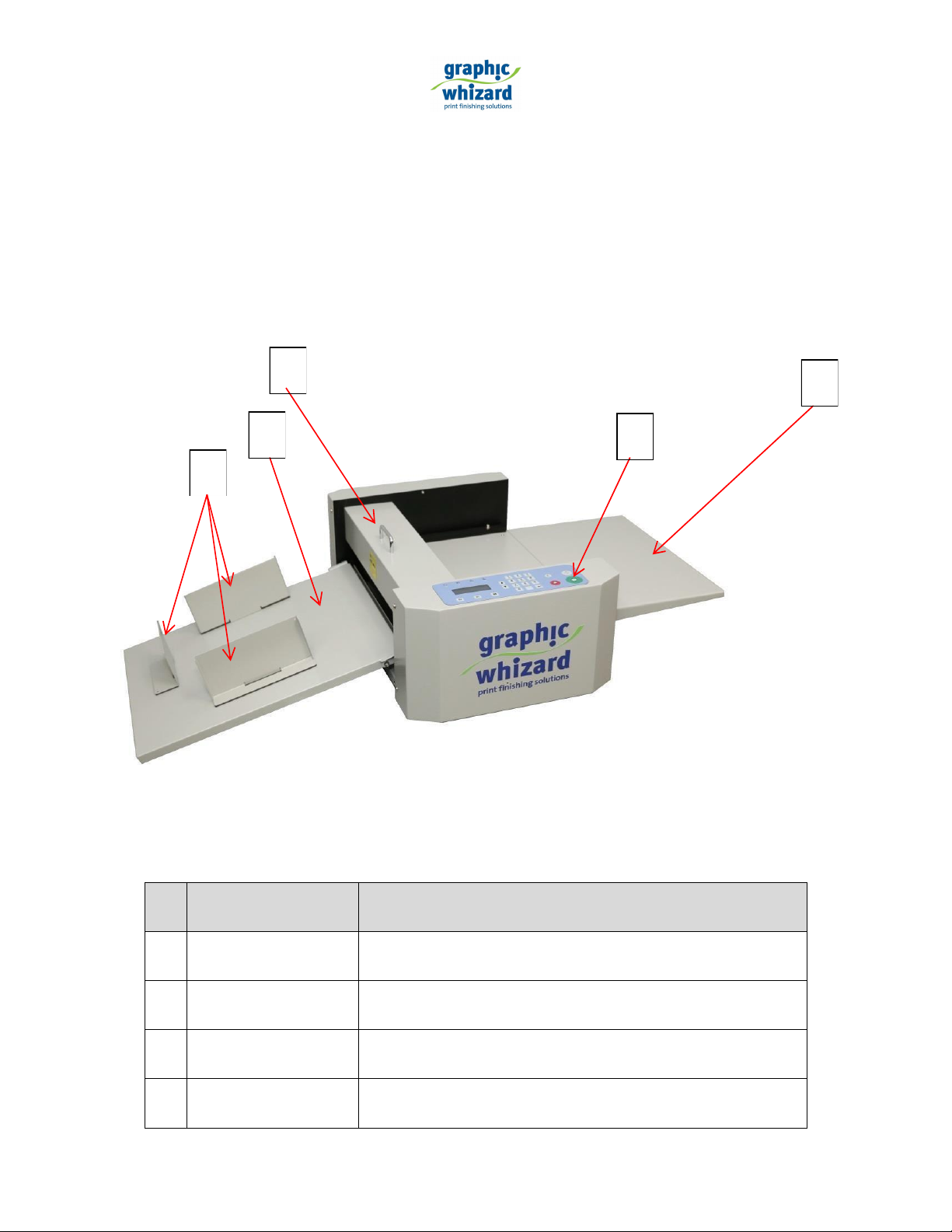

Main Parts and Assemblies....................................................................................................................................4

Outfeed Tray......................................................................................................................................................5

Outfeed Assembly .............................................................................................................................................5

Additional Parts .................................................................................................................................................6

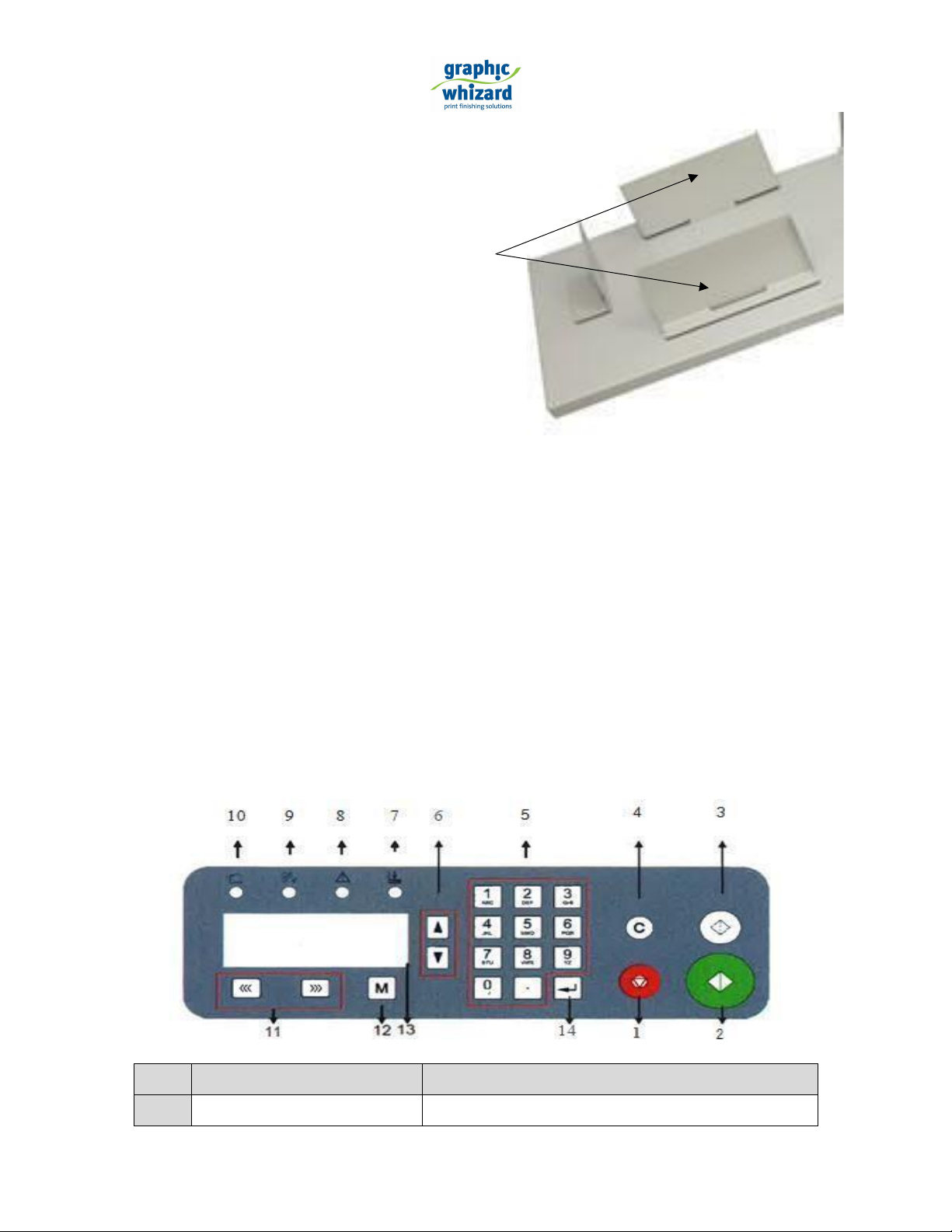

Display and Keypad................................................................................................................................................7

Operation...............................................................................................................................................................8

Main Screen.......................................................................................................................................................9

Input Crease Data..............................................................................................................................................9

Recall Job .........................................................................................................................................................10

Save Job ...........................................................................................................................................................10

Speed ...............................................................................................................................................................10

Troubleshooting...................................................................................................................................................10

Skew Adjustment.............................................................................................................................................11

Crease Depth Adjustment ...............................................................................................................................12

Maintenance........................................................................................................................................................12