2

2020-10-20

Table of Contents

Introduction........................................................................................................3

Safety.................................................................................................................4

Specifications.....................................................................................................5

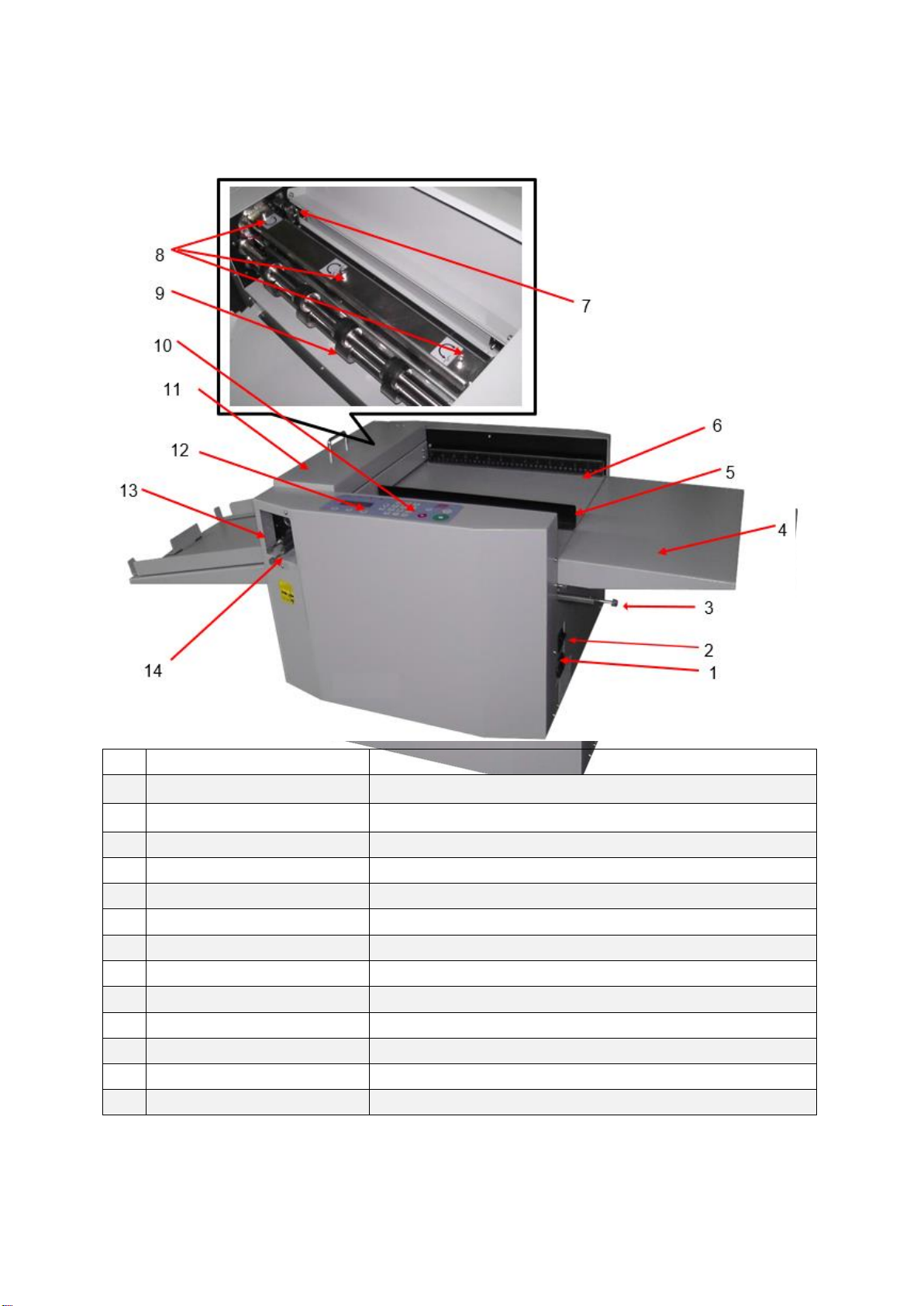

Overview............................................................................................................6

Keypad........................................................................................................7

Set Up................................................................................................................8

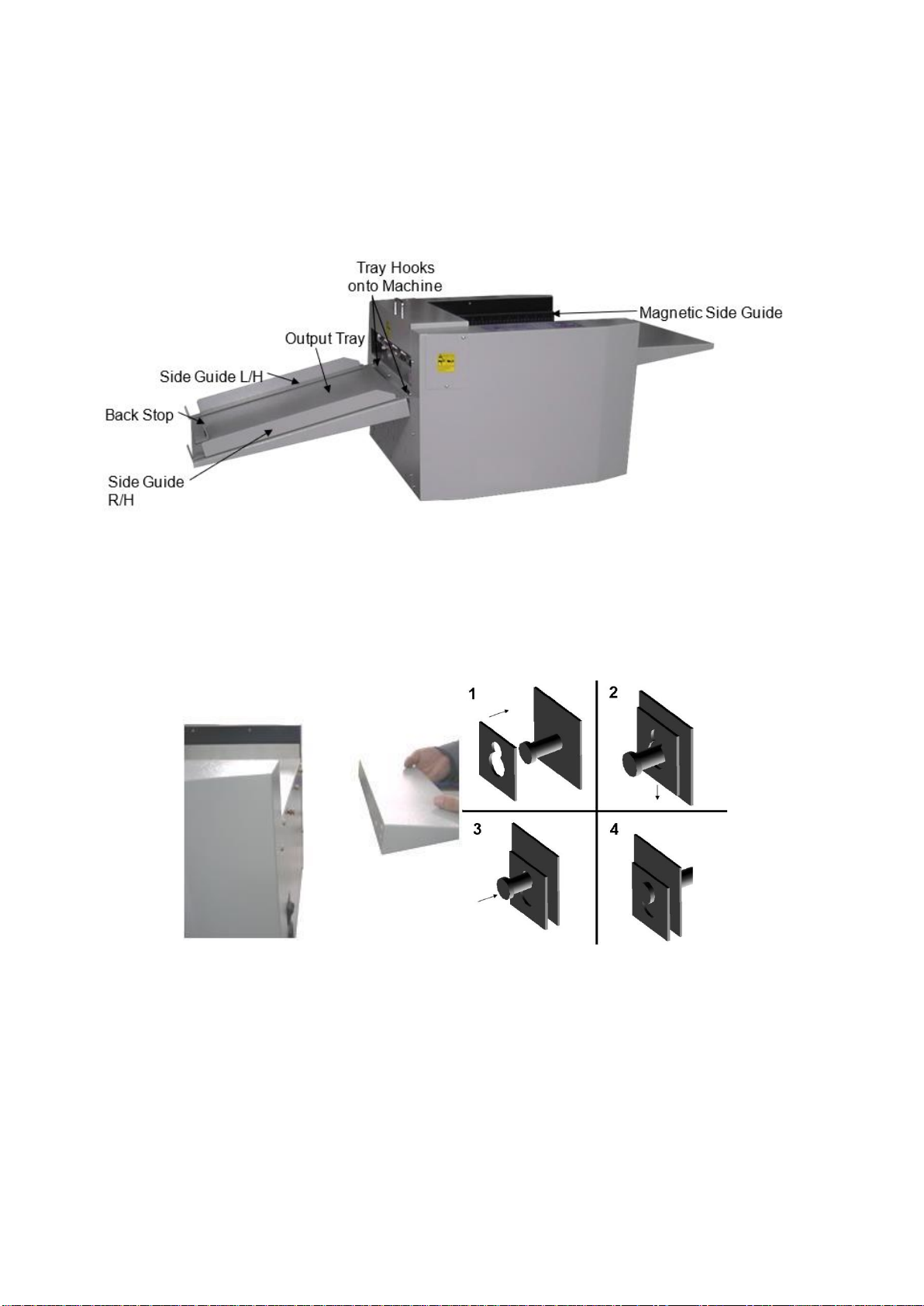

Output Tray, Stops and Guides...................................................................8

Feed Table Extension.................................................................................8

Power Socket and Switch ...........................................................................9

Quick Start.......................................................................................................10

Programming a Crease Job......................................................................10

Screen Operation.............................................................................................11

Welcome Screen.......................................................................................11

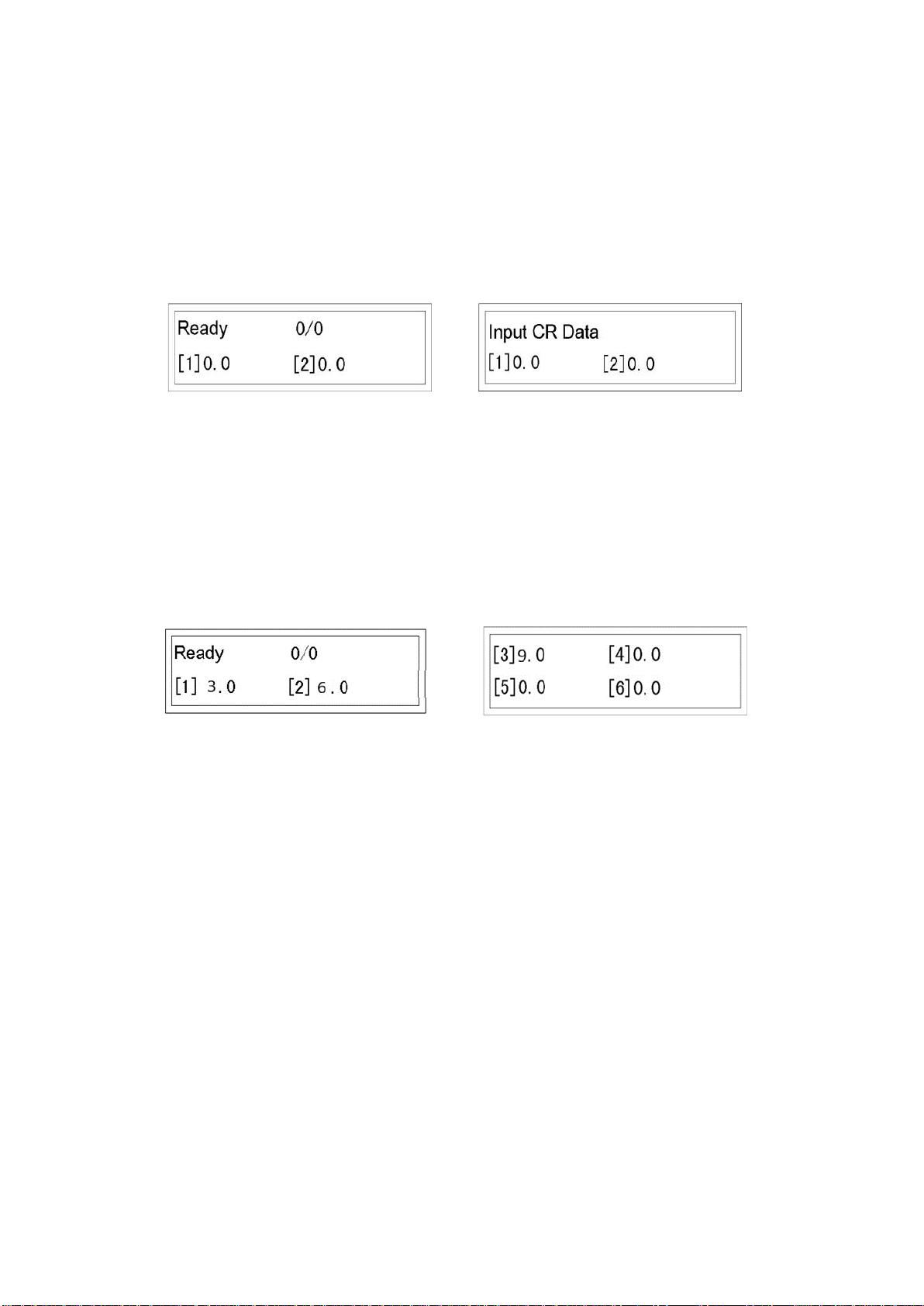

Ready Screen ...........................................................................................11

Crease Data Screen..................................................................................12

Cover Hinge Screen..................................................................................13

Progressive Screen...................................................................................14

Saving Jobs Screen..................................................................................16

Recalling Jobs Screen ..............................................................................16

Speed Screen ...........................................................................................17

Recalibration Screen.................................................................................17

Hardware Setting.............................................................................................18

Skew Adjustment ......................................................................................18

Crease Depth............................................................................................18

Adjusting the Crease Depth...............................................................19

Slide-in Tools...................................................................................................20

Installing the Tools:...................................................................................20

Perf Crash Pad .........................................................................................21

Replacing the Crash Pad...................................................................21

Optional Parts..................................................................................................22

Perforating Wheel .....................................................................................22

Trouble Shooting..............................................................................................25

C-1 Top Cover Open.................................................................................25

C-2 Paper Jam at Infeed Roller.................................................................26

C-3 Paper Jam at Outfeed Roller..............................................................27

E-1 Crease Motor Error.............................................................................28

Maintenance ....................................................................................................29