1

1/13/2021

Table of Contents

Chapter 1 Introduction .................................................................................................................................................3

1.1 Preface................................................................................................................................................................3

1.2 Safety ..................................................................................................................................................................3

Power Supply ........................................................................................................................................................3

Chapter 2 Specifications ...............................................................................................................................................4

Chapter 3 Main Parts & Assemblies .............................................................................................................................5

Chapter 4 Installation ...................................................................................................................................................7

4.1 Unboxing and Inspection....................................................................................................................................7

4.2 Machine Assembly..............................................................................................................................................8

4.2.1 Outfeed Tray and Card Catcher ...................................................................................................................8

4.2.2 Extension Table Installation.........................................................................................................................8

4.2.3 Power Socket and Switch.............................................................................................................................8

Chapter 5 Operation.....................................................................................................................................................9

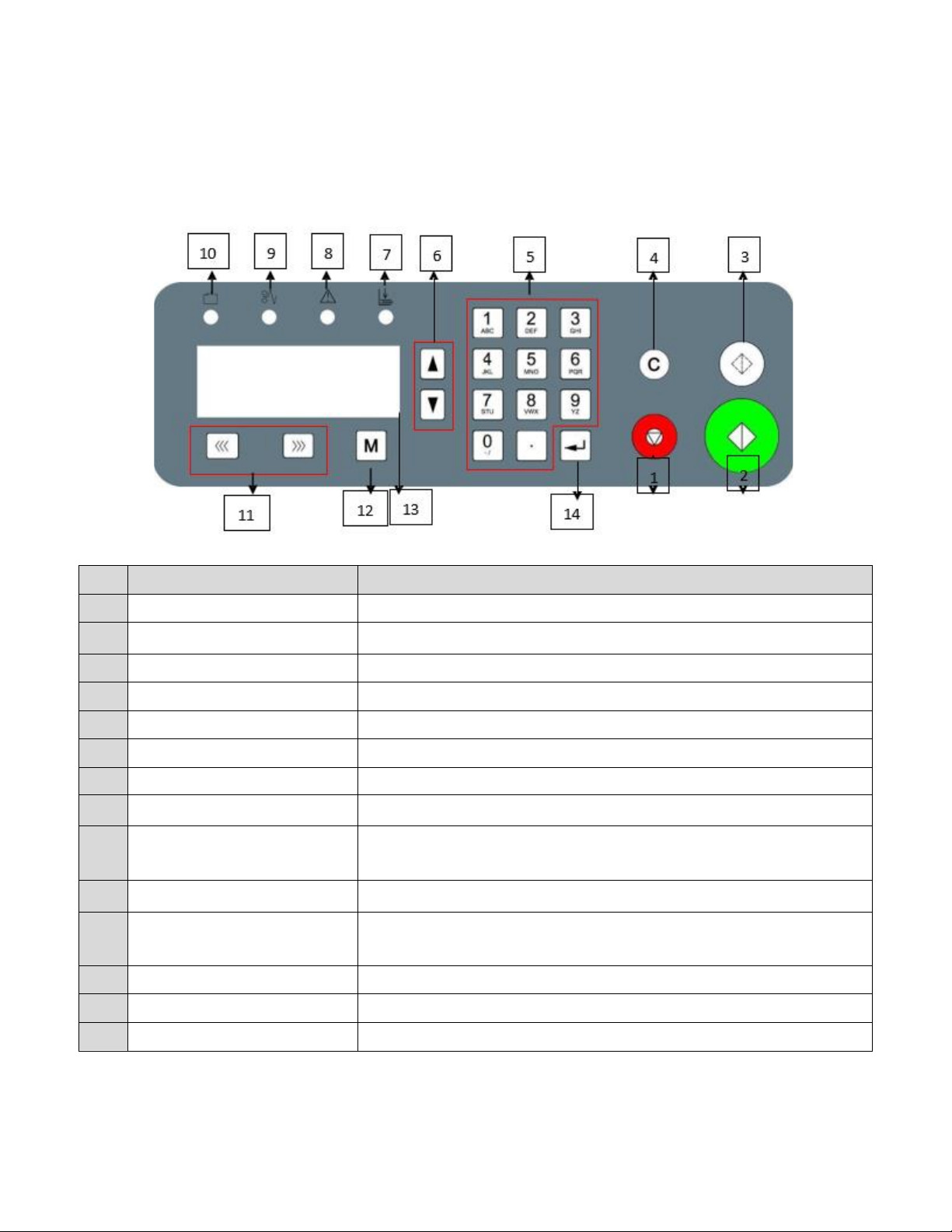

5.1 Key Panel Introduction .......................................................................................................................................9

5.2 Quick Start ........................................................................................................................................................10

5.3 Screen ...............................................................................................................................................................10

5.3.1 Welcome Screen........................................................................................................................................10

5.3.2 Ready Screen..............................................................................................................................................10

5.3.3 Mode Introduction.....................................................................................................................................12

5.3.4 Smart Input Mode......................................................................................................................................16

5.3.5 Job Layout Creation ...................................................................................................................................18

5.3.6 Parameters.................................................................................................................................................18

5.3.7 Job Layout Parameters ..............................................................................................................................19

5.3.8 How to Create a Register Mark..................................................................................................................23

5.3.9 How to use a Register Mark.......................................................................................................................24

5.3.10 Using the Cut Mark Registration..............................................................................................................24

5.4 Hardware Setting..............................................................................................................................................25

5.4.1 Side Guide Setting......................................................................................................................................25

5.4.2 Positioning Slitters .....................................................................................................................................25

5.4.3 Skew Adjustment.......................................................................................................................................26

5.4.4 Outfeed Tray Setting..................................................................................................................................27