GRAPHTEC WR300 User manual

WR300

USER’S MANUAL

MANUAL NO. WR300-UM-151

THERMAL ARRAYCORDER

Introduction

i

Introduction

Thank you for purchasing a WR300 Series ThermalArraycorder. Please read this manual thoroughly before

attempting to use your new product to ensure that you use it correctly and to its full potential.

Notes on Use

Be sure to read all of the following notes before attempting to use the WR300 Series ThermalArraycorder.

1. Note on the CE Marking

The WR300 Series complies with the EN61326 (1997+A1:1998+A2:2001 Class A) standard based on the

EMC directive (89/336/EMC). It also conforms to the EN61010-1 (1993/A2:1995) standard based on the LV

directive (72/73/EEC).

Although the WR300 Series complies with the above-mentioned standards, be sure to use it correctly in

accordance with the instructions and notes provided in its User's Manual.

Moreover, use of the WR300 Series by incorrect procedures may result in damage to the WR300 Series or

may invalidate its safeguards. Please confirm all of its notes regarding use and other related information to

ensure correct use.

2. Warning

This is a Class A product according to the EMC directive.

In a domestic environment, this product may cause radio interference or may be affected by radio

interference to the extent that proper measurement cannot be performed.

3. Notes for Safe Operation

(1) Be sure to use the Graphtec-supplied AC power cable. In environments where there is a lot of noise or

where the power supply is unstable, we recommend that you ground the WR300 Series.

(2) When a high-voltage signal cable has been connected to the main unit's analog signal input terminal,

avoid touching the leads of the input terminal's signal cable to prevent electrical shock due to high

voltage.

(3) Ensure that the WR300 Series power source is positioned so that it can easily be disconnected.

4. Notes on Functions and Performance

(1) Be sure to connect the main unit to an AC or DC power supply that conforms to the rated range.

Connection to a non-rated power supply may cause the main unit to overheat and break down.

(2) Do not block the vent on the main unit.

Continued operation with the vent blocked may cause the main unit to overheat and break down.

(3) To avoid malfunctions and other damage, avoid using the WR300 Series in the following locations.

• Places exposed to high temperature and/or high humidity, such as in direct sunlight or near heating

equipment. (Operating range - Temperature: 0 to 40°C, Humidity: 30 to 80% RH)

•Locations subject to excessive salt spray or heavy fumes from corrosive gas or solvents.

•Excessively dusty locations.

•Locations subject to strong vibrations or shock.

•Locations subject to surge voltages and/or electromagnetic interference.

(4) Use the chart paper supplied by Graphtec. The print quality cannot be guaranteed if other paper types

are used.

(5) If the main unit becomes soiled, wipe it off using a soft, dry cloth. Use of organic solvents (such as

thinner or benzene) causes deterioration and discoloration of the outer casing.

ii

Introduction

(6) In the course of use, the thermal head gradually becomes soiled which will lower the print quality. If this

happens, it is recommended to clean it using the optional B-368 head cleaner kit. If the print quality does

not improve even after using the head cleaner, contact your sales representative or nearest Graphtec

vendor.

(7) Do not use the WR300 Series in the vicinity of other devices which are susceptible to electromagnetic

interference.

(8) Measured results may not conform to the stated specifications if the WR300 Series is used in an

environment which is subject to strong electromagnetic interference.

(9) Insofar as possible, position the WR300 Series input signal cables away from any other cables which

are likely to be affected by electromagnetic interference.

(10)For stabilized measurement, allow the WR300 Series to warm up for at least 30 minutes after turning it

on.

To Ensure Safe and Correct Use

iii

To Ensure Safe and Correct Use

• To ensure safe and correct use of the WR300 Series, read this Manual thoroughly before use.

• After having read this Manual, keep it in a handy location for quick reference as needed.

• Do not permit small children to touch the WR300 Series.

• The following describes important points for safe operation. Please be sure to observe them strictly.

Conventions Used in This Manual

To promote safe and accurate use of the WR300 Series as well as to prevent human injury and property

damage, safety precautions provided in this manual are ranked into the five categories described below. Be

sure you understand the difference between each of the categories.

DANGER

This category provides information that, if ignored, is highly likely to cause fatal or serious injury to

the operator.

WARNING

This category provides information that, if ignored, is likely to cause fatal or serious injury to the

operator.

CAUTION

This category provides information that, if ignored, could cause physical damage to the WR300

Series.

HIGH TEMPERATURE

This category provides information that, if ignored, is likely to cause burns or other injury to the

operator due to contact with high temperature.

ELECTRICAL SHOCK

This category provides information that, if ignored, is likely to expose the operator to electrical

shock.

Description of Safety Symbols

The symbol indicates information that requires careful attention (which includes warnings).

The point requiring attention is described by an illustration or text within or next to the symbol.

The symbol indicates action that is prohibited. Such prohibited action is described by an

illustration or text within or next to the symbol.

The symbol indicates action that must be performed. Such imperative action is described by an

illustration or text within or next to the symbol.

iv

Safety Precautions

Safety Precautions

WARNING

Be sure to securely connect the WR300 Series power cord.

• After checking that the Power switch is turned off, connect the power cord's

female plug to the WR300 Series and then connect its male plug into the

electrical socket.

•Use of the WR300 Series without the power cord securely plugged into the

electrical socket may result in electrical shock due to current leakage.

• Before running the WR300 Series using a DC power supply, be sure to

ground the protective ground terminal ( ) to avoid electrical shock and

fire hazards. For grounding, use a ground wire with a diameter of at least

0.75 mm2.

When using the WR300 Series in an environment where grounding is not

possible, ensure that the voltage to be measured is no greater than 50 V

(DC or rms).

If the WR300 Series generates smoke, is too hot, emits a strange odor, or otherwise functions abnormally,

turn off its power and unplug its power cord from the electrical socket.

•Use of the WR300 Series in such status may result in a fire hazard or

electrical shock.

•After checking that smoke is no longer being generated, contact your sales

representative or nearest Graphtec vendor to request repair.

•Never try to perform repair yourself. Repair work by inexperienced

personnel is extremely dangerous.

Before turning on the WR300 Series, ensure that the electric socket's supply voltage conforms to the

WR300 Series power rating.

• Use of a different supply voltage may cause damage to the WR300 Series

or a fire hazard due to electrical shock or current leakage.

Never disassemble or remodel the WR300 Series.

•Such action may cause a fire hazard due to electric shock or current

leakage.

• Contact with a high-voltage component inside the WR300 Series may

cause electric shock.

• If repair is required, contact your sales representative or nearest Graphtec

vendor.

Avoid using the WR300 Series in extremely dusty or humid places.

•Such use may cause a fire hazard due to electrical shock or current

leakage.

Securely connect the power cord

Make sure that the socket has a good

protective ground

Use of a different

supply voltage

prohibited

Amateur repair

prohibited

No disassembly

Use prohibited

Watch out for

electrical shock

Safety Precautions

v

Safety Precautions

WARNING

Avoid using the WR300 Series in places where it may be exposed to water such as bathrooms, locations

exposed to wind and rain, and so on.

Prevent dust or metallic matter from adhering to the power supply connector.

•Adhesion of foreign matter may cause a fire hazard due to electrical shock

or current leakage.

Never use a damaged power cord.

•Use of a damaged cord may result in a fire hazard due to electrical shock.

•If the cord becomes damaged, order a new one to replace it.

Avoid water

Watch out for

electrical shock

Unplug the power

cord from the socket

No foreign matter

Watch out for

electrical shock

vi

Safety Precautions

Safety Precautions

CAUTION

Do not use or store the WR300 Series in a location exposed to direct sunlight or the direct draft of an air

conditioner or heater.

• Such location may impair the WR300 Series performance.

Do not place coffee cups or other receptacles containing fluid on the WR300 Series.

• Fluid spilling inside the v may cause a fire hazard due to electrical shock or

current leakage.

Do not use the WR300 Series in a location subject to excessive mechanical vibration or electrical noise.

• Such location may impair the WR300 Series performance.

To insert or disconnect the power cord or a signal input cable, grasp the power cord's plug or the signal

input cable's connector.

•Pulling the cord/cable itself damages the cord/cable, resulting in a fire

hazard or electrical shock.

If fluid or foreign matters enters inside the WR300 Series, turn off the Power switch and disconnect the

power cord from the electrical socket.

• Use in such status may cause a fire hazard due to electrical shock or

current leakage.

•Contact your sales representative or nearest Graphtec vendor to request

repair.

Do not input voltage that exceeds the permissible input voltage range that is specified on the WR300

Series label.

•Exceeding the specified voltage input range may cause electrical shock or

a fire hazard.

Storage/Use prohibited

Use prohibited

Unplug the power

cord from the socket

No pulling

Use prohibited

Avoid fluids

Watch out for

electrical shock

Safety Precautions

vii

Do not attempt to lubricate the WR300 Series mechanisms.

•Such action may cause the WR300 Series to break down.

Never clean the WR300 Series using a volatile solvent (such as thinner or benzine).

• Such action may impair the WR300 Series performance.

• Clean off any soiled areas using a soft dry cloth.

Safety Precautions

CAUTION

No lubrication

No volatile solvents

viii

Contents

CONTENTS

Introduction ........................................................................................................................................................i

To Ensure Safe and Correct Use ..................................................................................................................... iii

Conventions Used in This Manual ......................................................................................................... iii

Description of Safety Symbols............................................................................................................... iii

Safety Precautions........................................................................................................................................... iv

1General Description

1.1 Overview..................................................................................................................................... 1-2

1.2 Features...................................................................................................................................... 1-2

1.3 Operating Environment............................................................................................................. 1-3

Ambient Operating Conditions..................................................................................................... 1-3

Warming-up Before Use .............................................................................................................. 1-3

Configuration When in Use.......................................................................................................... 1-3

1.4 Notes on Temperature Measurement....................................................................................... 1-4

1.5 Notes on Using the Monitor...................................................................................................... 1-4

1.6 Changing the Display Language.............................................................................................. 1-4

1.7 Protecting the Thermal Head.................................................................................................... 1-4

2Checks and Preparation

2.1 Checking the Outer Casing....................................................................................................... 2-2

2.2 Checking the Accessories ........................................................................................................ 2-2

2.3 WR300/310 Part Names and Functions ................................................................................... 2-3

2.4 Monitor Part Names and Functions ......................................................................................... 2-4

Direct Settings (Selecting the Measurement Parameters) .......................................................... 2-4

2.5 Control Panel Part Names and Functions............................................................................... 2-5

2.6 Amplifier Part Names and Functions....................................................................................... 2-7

V amplifier.................................................................................................................................... 2-7

M amplifier ................................................................................................................................... 2-8

DCB amplifier .............................................................................................................................. 2-9

FV Amplifier ................................................................................................................................. 2-9

Logic amplifier............................................................................................................................ 2-10

2.7 Installing or Removing an Amp ...............................................................................................2-11

2.8 The Printer Units and Compatible Chart Paper .................................................................... 2-12

2.9 Loading Chart Paper ............................................................................................................... 2-13

Loading Roll Paper .................................................................................................................... 2-13

Loading Z-fold Paper Internally (Option) ................................................................................... 2-14

Loading Z-Fold Paper in the Long-Length Z-Fold Unit (Option) ................................................ 2-15

Cutting the Chart Paper ............................................................................................................. 2-16

2.10 Inserting and Removing a PCMCIA Card .............................................................................. 2-17

2.11 Connecting the Power Cable and Turning on the Power..................................................... 2-18

Connecting to an AC Power Supply .......................................................................................... 2-18

Connecting to a DC Power Supply ............................................................................................ 2-19

2.12 Connecting to a PC.................................................................................................................. 2-20

Connection Using a LAN Cable................................................................................................. 2-20

Connection Using a USB Cable ................................................................................................ 2-20

2.13 Remote Functions and Connector Pin Assignments........................................................... 2-21

2.14 Assembling the Remote Connector....................................................................................... 2-22

2.15 Using the IRIG Terminals (WR310 only) ................................................................................ 2-23

Contents

ix

3Recorder Mode

3.1 Recorder Mode Menu Tree Structure....................................................................................... 3-2

3.2 Amp Settings.............................................................................................................................. 3-4

Amp Settings ............................................................................................................................... 3-4

Scaling, Lower - SPAN - Upper, Unit ........................................................................................... 3-5

Notes on Logic............................................................................................................................. 3-7

3.3 Memory Settings........................................................................................................................ 3-8

3.4 Trigger Settings ........................................................................................................................3-11

Possible Combinations of Source Settings................................................................................ 3-15

3.5 Record Settings ....................................................................................................................... 3-16

3.6 Data Replay Settings............................................................................................................... 3-18

3.7 Format Settings ....................................................................................................................... 3-20

3.8 EU Settings............................................................................................................................... 3-22

3.9 Annotation Settings................................................................................................................. 3-24

3.10 Calculation Settings ................................................................................................................ 3-25

3.11 System Settings....................................................................................................................... 3-28

3.12 Option Settings ........................................................................................................................ 3-29

3.13 Customize Settings ................................................................................................................. 3-30

3.14 System Information ................................................................................................................. 3-31

3.15 Recorder Mode REPLAY Menu Tree Structure ..................................................................... 3-32

3.16 Replay Settings........................................................................................................................ 3-33

3.17 Cursor Settings and Cursor Position .................................................................................... 3-34

3.18 Search Settings ....................................................................................................................... 3-35

3.19 Execute Operations ................................................................................................................. 3-37

3.20 Calculation ............................................................................................................................... 3-39

4FFT Mode

4.1 FFT Menu Tree Structure .......................................................................................................... 4-2

4.2 FFT Mode Settings..................................................................................................................... 4-3

4.3 Record Settings ......................................................................................................................... 4-4

4.4 FFT Mode REPLAY Menu Tree Structure............................................................................... 4-10

4.5 REPLAY Menu ...........................................................................................................................4-11

5Application Software

5.1 Procedures from Installation to Measurement ....................................................................... 5-2

5.2 Software System Requirements............................................................................................... 5-3

5.3 Connecting to a PC.................................................................................................................... 5-4

Connection Using a LAN Cable................................................................................................... 5-4

Connection Using a USB Cable .................................................................................................. 5-5

5.4 Installing the Software .............................................................................................................. 5-6

Checking the version of your USB driver (when already installed).............................................. 5-6

Installing the USB driver .............................................................................................................. 5-6

Installing OPS023........................................................................................................................ 5-8

5.5 Setting the IPAddress and Device ID ...................................................................................... 5-9

5.6 Menu Configuration and System Settings ............................................................................ 5-10

Starting the Software ................................................................................................................. 5-10

Menu Configuration ....................................................................................................................5-11

Measurement Data Save Destination Settings and Other Settings........................................... 5-12

Default Color Settings................................................................................................................ 5-13

OPS023 Transfer Settings......................................................................................................... 5-14

Synchronizing the Date and Time.............................................................................................. 5-15

5.7 Measurement Parameter Setting Procedures....................................................................... 5-16

Amplifier Settings....................................................................................................................... 5-16

x

Contents

Trigger Settings ......................................................................................................................... 5-17

Memory Settings........................................................................................................................ 5-18

Span Settings ............................................................................................................................ 5-19

EU Settings................................................................................................................................ 5-19

Format Settings ......................................................................................................................... 5-20

Start/Stop/Monitor/Replay ......................................................................................................... 5-21

Loading and Saving Setup Parameters..................................................................................... 5-21

5.8 Printer Functions ..................................................................................................................... 5-23

5.9 Measurement/Monitoring Procedures and Save/Scroll/Cursor Functions ........................ 5-24

Starting Measurement to Saving Data....................................................................................... 5-24

Saving Measurement Data ........................................................................................................ 5-24

Scrolling Measurement Data ..................................................................................................... 5-24

Cursor Functions ....................................................................................................................... 5-25

Searching and Jumping to Specific Points ................................................................................ 5-25

2-Screen Display ....................................................................................................................... 5-26

5.10 Opening Captured Data Files and Saving WR300-Captured Data to a PC ......................... 5-28

Opening Captured Data Files on a PC ...................................................................................... 5-28

Saving Data Captured in the WR300 to a PC ........................................................................... 5-28

Displaying Data Captured in the WR300 on a PC..................................................................... 5-29

5.11 Converting the Data Format and Saving the Data ................................................................ 5-30

Convert and Save Data ............................................................................................................. 5-30

Batch Conversion ...................................................................................................................... 5-31

5.12 Report Function ....................................................................................................................... 5-33

5.13 Exiting OPS023 ........................................................................................................................ 5-34

6Specifications

6.1 WR300 Series Model Configuration Chart............................................................................... 6-2

6.2 Basic Specifications.................................................................................................................. 6-3

Main Unit Specifications .............................................................................................................. 6-3

Data Capture Function Specifications ......................................................................................... 6-3

Monitor and Printer Specifications............................................................................................... 6-4

Trigger Specifications .................................................................................................................. 6-5

Software Specifications ............................................................................................................... 6-5

6.3 Plug-in Amplifier Specifications............................................................................................... 6-6

WR3-V Amplifier (for voltage measurement) Specifications ........................................................ 6-6

WR3-M Amplifier (for voltage/temperature measurement) Specifications ................................... 6-7

WR3-DCB Amplifier (for strain measurement) Specifications ..................................................... 6-8

WR3-FV Amplifier (for frequency measurement) Specifications ................................................. 6-8

Logic Amplifier (for measurement of logic signals) Specifications ............................................... 6-9

IRIG (Time Code) Specifications (WR310 only) .......................................................................... 6-9

6.4 Option Specifications.............................................................................................................. 6-10

12 V DC Drive Specifications ....................................................................................................6-10

6.5 Options/Accessories/Supplies Charts ...................................................................................6-11

Units ...........................................................................................................................................6-11

Accessories ................................................................................................................................6-11

Supplies......................................................................................................................................6-11

6.6 External Dimensions ............................................................................................................... 6-12

Index.......................................................................................................................................................... I-1

1-2

General Description

1.1 Overview

The WR300/310 ThermalArraycorder is a compact, lightweight recorder that comes with a large-screen color

display panel and a large-capacity hard disk (models with a built-in hard disk only).

The WR300/310 employs a large-screen color LCD (Liquid Crystal Display) for its display panel and a

thermal printhead in its printer unit, enabling high-speed display and high-speed recording.

Moreover, use of the PCMCIA card and the large-capacity hard disk* permits direct storage of a large volume

of measured data.

* WR310 only

1.2 Features

Input

(1) The adoption of plug-in type amp units lets you choose amps to suit a variety of objects for

measurement.

(2) The recorder is equipped with dedicated keys that enable amp-related settings to be specified using

interactive menu screens.

Display

(1) With the 8.4-inch TFT color liquid crystal display, you can confirm the waveforms of measured data and

each channel's settings at a glance.

Recording

(1) Recording on chart paper, up to a maximum chart speed of 50 mm/second, demonstrates its full power

during realtime waveform recording of high-speed events.

(2) The recording zone for each channel can be separately set, enabling revision of the recording format to

suit individual applications.

Data Capture

(1) Concurrently with recording, a large volume of measured data can be saved at high speed to a PCMCIA

card or large-capacity hard disk*.

(2) Even after saving a large volume of data, use of the Search function lets you easily retrieve the required

portion of the data.

*WR310 only

Data Control & Processing

(1) The software provided lets you set conditions and monitor data on a computer using the USB or TCP/IP

interface.

(2) Captured data can be read from the OPS023 software to files and displayed for processing.

(3) Data can be transferred off-line to a computer using memory media (PCMCIAcards).

General Description

1-3

1.3 Operating Environment

This section explains the operating environment for the WR300/310.

Ambient Operating Conditions

(1) Ambient temperature and humidity (the WR300/310 must be operated within the following ranges.)

•Temperature range: 0 to 40°C

•Humidity range: 30 to 80% RH

(2) Environment (do not use in the following locations.)

• Locations in direct sunlight or with high humidity, such as near heaters

•Locations exposed to salty air, corrosive gases, or organic solvents

•Dusty locations

•Locations subject to vibration or impact

•Locations subject to voltage surge or electromagnetic interference such as lightning or electric

furnaces

(3) Installation category (over-voltage category)

•The WR300/310 conforms to the IEC664 installation category I

CHECKPOINT

If condensation occurs...

Condensation occurs in the form of water droplets on the device surfaces and interior when the WR300/310 is moved

from a cold to a warm location. Using the WR300/310 with condensation will cause malfunctioning. Wait until the

condensation has disappeared before turning on the power.

Warming-up Before Use

The WR300/310 should be allowed to warm up with the power turned on for approximately 30 minutes to

ensure that it operates according to the specified performance.

Configuration When in Use

The WR300/310 must always be laid flat when in use.

WR300-8

CAUTION

Do not block the air vent on the WR300/310, as this will cause malfunctioning.

1-4

General Description

1.4 Notes on Temperature Measurement

Please observe the following precautions when using the WR3-M AMP (voltage/temperature amp) to perform

temperature measurement.

(1) Do not block the air vents. Always provide a space of at least 30 cm on all sides of the WR300/310.

(2) For stabilized temperature measurement, allow the WR300/310 to warm up for at least 30 minutes after

turning it on.

(3) Exposure of the WR3-M AMP's (voltage/temperature amp) input terminals to direct drafts, direct sunlight,

or abrupt changes in temperature may impair the equilibrium of the input parts and result in

measurement errors. To measure temperature in such an environment, take appropriate

countermeasures such as changing the installation site of the WR300/310.

1.5 Notes on Using the Monitor

The monitor is an LCD display unit, and so the display will vary depending on the operating environment.

CHECKPOINT

If the screen saver function is used, it will operate and clear the screen if no operations are performed during the

preset time. If the screen saver operates, press any key to restore the display.

CAUTION

• Condensation may form on the LCD screen if the WR300/310 is moved from a cold to a warm location. If this

occurs, wait until the LCD screen warms up to room temperature.

• The LCD screen is manufactured to extremely high precision. Black dots may appear, or red, blue, and green dots

may not disappear. Likewise, streaks may appear when viewed from certain angles. These phenomena are due to

the LCD screen construction, and are not signs of a fault.

1.6 Changing the Display Language

You can choose English, French, or Japanese as the language displayed on the screen. The default display

language is set to English (US) when the WR300/310 is shipped overseas. To change the display language,

see the instructions in "Changing the Display Language".

1.7 Protecting the Thermal Head

This recorder is provided with a circuit for protecting the thermal printhead. When the solid-fill area of

recording is large, this circuit protects the thermal printhead by lowering the print density so that current

above a stipulated level will not flow to the thermal printhead.

As soon as the solid-fill area of recording is decreased, the print density automatically resumes its usual

level.

In the event that the print density fluctuates too often, reduce the solid-fill area of recording by such means

as changing the Record Format setting, lowering the print density, and so on.

This chapter explains how to check the WR300/310's external casing

and accessories, and how to prepare the WR300/310 for operation.

CHAPTER 2

Checks and Preparation

2.1 Checking the Outer Casing

2.2 Checking the Accessories

2.3 WR300/310 Part Names and Functions

2.4 Monitor Part Names and Functions

2.5 Control Panel Part Names and Functions

2.6 Amplifier Part Names and Functions

2.7 Installing or Removing an Amp

2.8 The Printer Units and Compatible Chart Paper

2.9 Loading Chart Paper

2.10 Inserting and Removing a PCMCIA Card

2.11 Connecting the Power Cable and Turning on the Power

2.12 Connecting to a PC

2.13 Remote Functions and Connector Pin Assignments

2.14 Assembling the Remote Connector

2.15 Using the IRIG Terminals (WR310 only)

2-2

Checks and Preparation

2.1 Checking the Outer Casing

After unpacking, check the WR300/310's outer casing before use. In particular, please check for the

following:

• Surface scratches

• Other flaws such as stains or dirt

2.2 Checking the Accessories

After unpacking, check that the following standard accessories are included. The accessories included will

differ depending on the model purchased.

Thermal paper

1 roll

Roll paper bobbins

2

REMOTE connector

1

CD-ROM

1

Roll length: 40 m

Contains: User’s Manual, Application Software

AC cable (RSC-110)

1

QuickStart Guide

2

Probe set (RIC-10) 4-ch models: 1 of each, 8-ch models: 2 of each, 16-ch models: 4 of each

Logic input cable (RIC-07) Alligator-clip cable (RIC-08)

IC-clip cable (RIC-09)

LCD Protector

1

Standard Accessories

DC power cable (RIC-140)

1

Fuse

2

Z-fold chart paper

1 pack

10-pin round connector

Chart paper length: 40 m

Slow-blow type

12V unit: 20A

When the DC drive unit is included

Additional Accessories

Z-fold chart paper (PZ231A)

1 pack

Long-length pipe

1

Chart paper length: 100 m

When the internal Z-fold chart paper unit is included

When the long-length Z-fold chart paper unit is included

Options

4ch : PR230(100 mm)

8/16ch : PR231A(200 mm)

4ch : PZ230(100 mm)

8/16ch : PZ233(200 mm)

Standard Accessories, Thermal paper (PR231A/PR231A), Roll paper bobbins, REMOTE connector, LCD Protector, CD-ROM, User's Manual,Application Software, QuickStart Guide, AC cable (RSC-

110), Additional Accessories, DC power cable (RIC-140), Fuse, Z-fold chart paper (PZ231A), Long-length pipe, Z-fold chart paper (PZ230/PZ233), Options, Probe set (RIC-10), Logic input cable

(RIC-07), Alligator-clip cable (RIC-08), IC-clip cable (RIC-09)

Checks and Preparation

2-3

2.3 WR300/310 Part Names and Functions

This section describes the names and functions of the WR300/310's parts.

(5) Logic amp

(4) Amplifier mounting section

(3) PCMCIA slot

(7) LAN connector

terminal

(8) USB connector terminal

(9) REMOTE

connector terminal

(11) Power switch

(10) AC power connector

(12) GND

(13) IRIG connector (WR310 only)

(14) Printer open lever

(2) Chart paper unit (1) Monitor

(6) Control panel keys

(1) Monitor.......................... Displays the setting menus and measurement data.

(2) Chart paper unit ............ Holds the roll paper and the Z-fold paper for internal use. If you want to use

long-length (100-m) Z-fold paper, the external long-length Z-fold paper unit is

required.

(3) PCMCIA slot .................. Used for inserting the PCMCIA card.

(4) Amplifier mounting section

.................................. Used for mounting the preamplifiers.

(5) Logic amp ...................... This is the logic amplifier.

(6) Control panel keys......... Used for the main operations, including settings, and starting and stopping

measurement.

(7) LAN connector terminal

.................................. Terminal for LAN connection.

(8) USB connector terminal

.................................. Terminal for USB connection.

(9) REMOTE connector terminal

.................................. Terminal for the Remote interface connector.

(10) AC power connector .... Terminal for connecting the AC power cable.

(11) Power switch................ Switch for turning on the power.

(12) GND............................. Used when a ground connection is required.

(13) IRIG connector (WR310 only)

.................................. Signal input/output terminal for IRIG time codes.

(14) Printer open leve ......... Used to open the printer cover when loading chart paper.

CHECKPOINT

To provide protection for the LCD screen, attach the LCD protector provided as a standard accessory.

2-4

Checks and Preparation

2.4 Monitor Part Names and Functions

(1) Measurement mode display area(11) Channel annotation area

(2) Date/time display area

(3) Chart speed display area

(4) Simplified message display area

(5) Monitor area

(7) Waveform/settings window display area

(9) Scale lower limit

(8) Span display area

(6) Position display area

(10) Scale upper limit

(1)

Measurement mode display area

.. Displays the measurement mode currently set.

(2) Date/time display area.................. Displays the current date and time. Moreover, displays IRIG time code

information when IRIG settings have been enabled.

(3) Chart speed display area.............. Displays the chart speed currently set.

(4) Simplified message display area .. Displays the system status.

For example, "Awaiting trigger" is displayed when waiting for a trigger

signal.

(5) Monitor area ................................. Displays the input signal values for each channel.

(6) Position display area .................... Displays the input signal positions for each channel.

(7) Waveform/settings window display area

................................................. Displays the measurement signal waveforms. The menu windows are

also displayed when the MENU key is pressed.

(8) Span display area......................... Displays the zone width (span) for the range set.

(9) Scale lower limit............................ Displays the lower limit of the scale set for each channel.

(10) Scale upper limit ......................... Displays the upper limit of the scale set for each channel.

(11) Channel annotation..................... Displays the user annotation set for each channel.

Direct Settings (Selecting the Measurement Parameters)

(2) MEAS

(1) CH

(3) RANGE

(4) FILT

(1) CH keys: Press to select the channel(s) for which measurement conditions can be specified.

(2) MEAS. key: Selects the input coupling status for each preamplifier. Each time you press this key, the

input coupling status changes.

(3) RANGE [ ] and [ ] keys: Select the measurement range for each channel. Each time you press a

RANGE key, the measurement range changes.

(4) FILT. key: Selects the filter mode. Each time you press the FILT. key, the filter mode changes.

Checks and Preparation

2-5

2.5 Control Panel Part Names and Functions

Direct Channel Operations

MODE

CLOSE

CANCEL

MENU

EXE.

MONITOR

ENTER

MEAS.

RANGE POSITION

CH

FILT. VERNI.

AUTO ZERO

LOCAL

TRIGGER

DISK

CURSOR

PRINTER

COPY

LIST

FEED

REPLAY

START

STOP

mm/s

mm/m

mm/h

125102050V1V2

UNIT

12345678

910111213141516

(2) (7)

(3)

(1)

(6)

(5)

(4)

(1) CH keys ......................... Select the channel number(s) for which measurement conditions can be

specified.

(2) MEAS. key..................... Selects the input coupling status.

(3) RANGE keys ................. The [ ] and [ ] keys select the measurement range.

(4) POSITION keys ............. The [ ] and [ ] keys specify the recording position. The position can also be

specified by using the MENU functions when the relevant menu is displayed.

(5) FILT. key ........................ Selects the filter mode.

(6) VERNI. key .................... Selects the Vernier function.

(7) AUTO ZERO key ........... Automatically moves the recording position to the origin point (cannot be used

for temperature measurement).

Printer Operations

MODE

CANCEL

MENU

EXE.

MONITOR

ENTER

MEAS.

POSITION

CH

FILT.

AUTO ZERO

LOCAL

TRIGGER

DISK

CURSOR

PRINTER

COPY

LIST

FEED

REPLAY

START

STOP

mm/s

mm/m

mm/h

125102050V1V2

UNIT

12345678

910111213141516

(2)

(1)

(3)

(4)

(5)

(6) (7) (8)

CLOSE

RANGE

VERNI.

(1) PRINTER key ................ Press this key to initiate recording of measured data.

(2) PRINTER LED............... Lights when recording to chart paper is enabled.

(3) COPY key ...................... Press this key to make a copy of the screen display.

(4) LIST key......................... Press this key to print a list of the currently selected measurement conditions on

chart paper.

(5) FEED key ...................... Press this key to advance the chart paper, without recording measured data.

(6) CHART SPEED keys..... Press one of these keys to set the chart speed to the value indicated on the key.

(7) V1/V2 keys .................... Press V1 or V2 to change the chart speed to the chart speed set for V1 or V2.

(8) Unit key.......................... Use to specify the chart speed as mm/s, mm/min, or mm/hr.

Table of contents

Popular Laboratory Equipment manuals by other brands

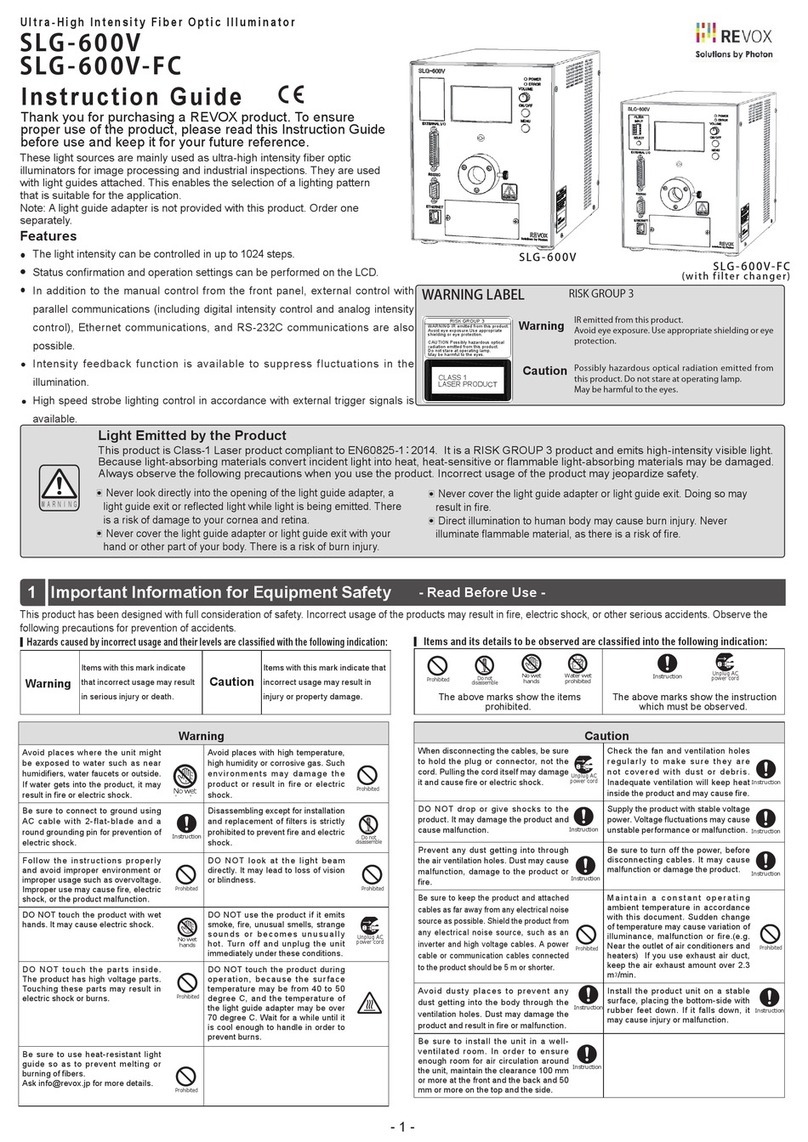

Campbell

Campbell CPEC200 Quick Deploy Guide

Thermo Scientific

Thermo Scientific KingFisher Plant DNA Kit instruction manual

Showa Denko

Showa Denko Shodex PROTEIN LS-G 4J Operation manual

cytiva

cytiva Kvick Lab Cassette Holder user manual

MasterCraft

MasterCraft MAXIMUM 057-4582-6 instruction manual

STEMCELL

STEMCELL ThawSTAR CFT2 quick start guide

Tissue-Tek

Tissue-Tek TEC 5100 operating manual

Thermo Scientific

Thermo Scientific KRILPRO installation guide

istok-audio

istok-audio ISTOK BREEZE Series user manual

Malvern

Malvern MICROCAL PEAQ-ITC operating instructions

Grant

Grant SAP Series Service manual

Thermo Scientific

Thermo Scientific Microm HM 430 instruction manual