3

Table of Contents

1 Introduction............................................................................................................................................4

1.1 Instructions...............................................................................................................................................4

1.2 Intended Use............................................................................................................................................4

1.3 Safety Instructions....................................................................................................................................5

1.4 Safety Marking.........................................................................................................................................5

1.5 Environment.............................................................................................................................................5

1.6 Technical Data..........................................................................................................................................6

1.7 Labels and Transfer Ribbon.....................................................................................................................7

2 Installation..............................................................................................................................................8

2.1 Preparing the Printer................................................................................................................................8

2.1.1 Removing the Front Cover .................................................................................................................8

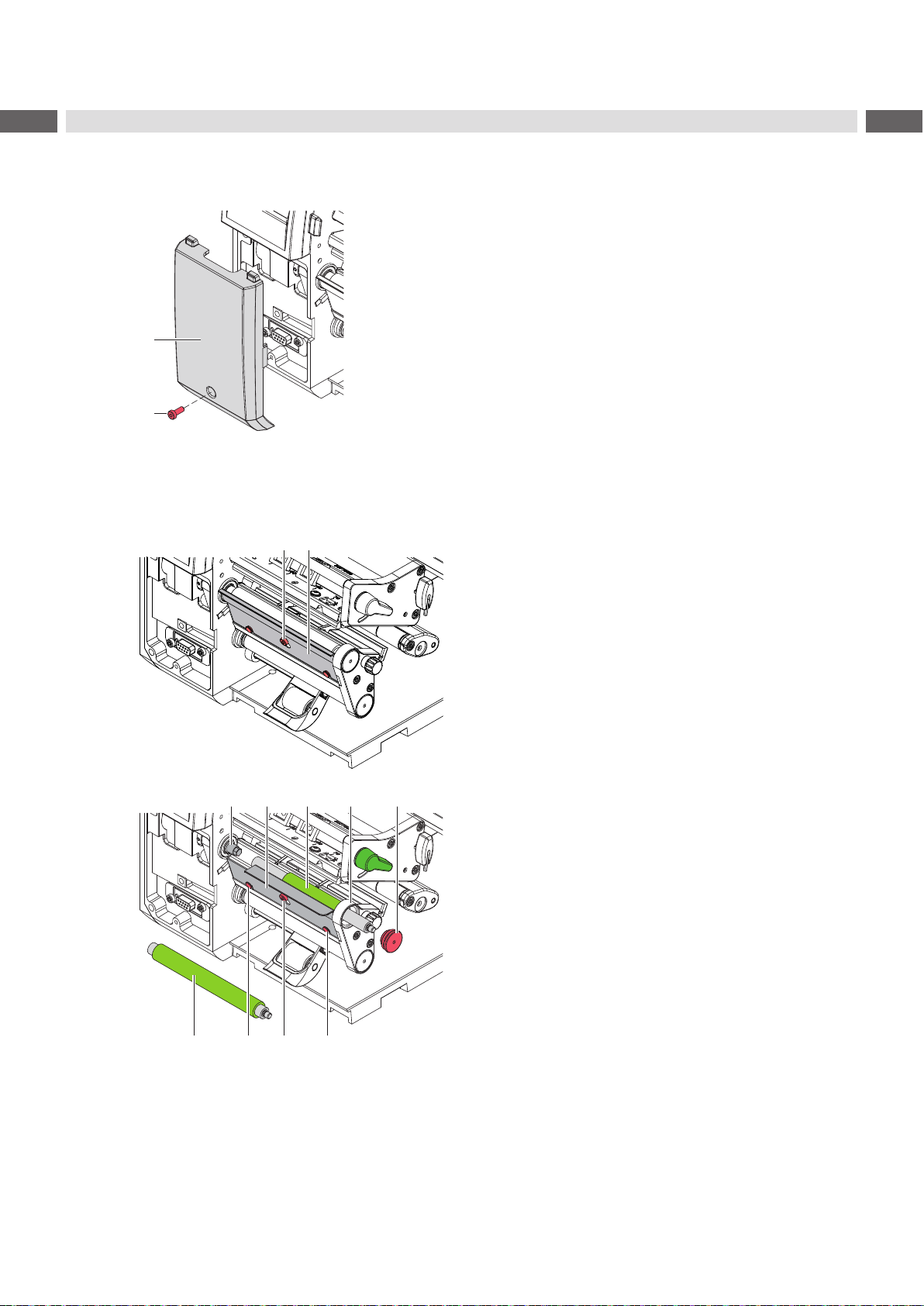

2.1.2 Replacing Peel-o Plate and Print Roller ...........................................................................................8

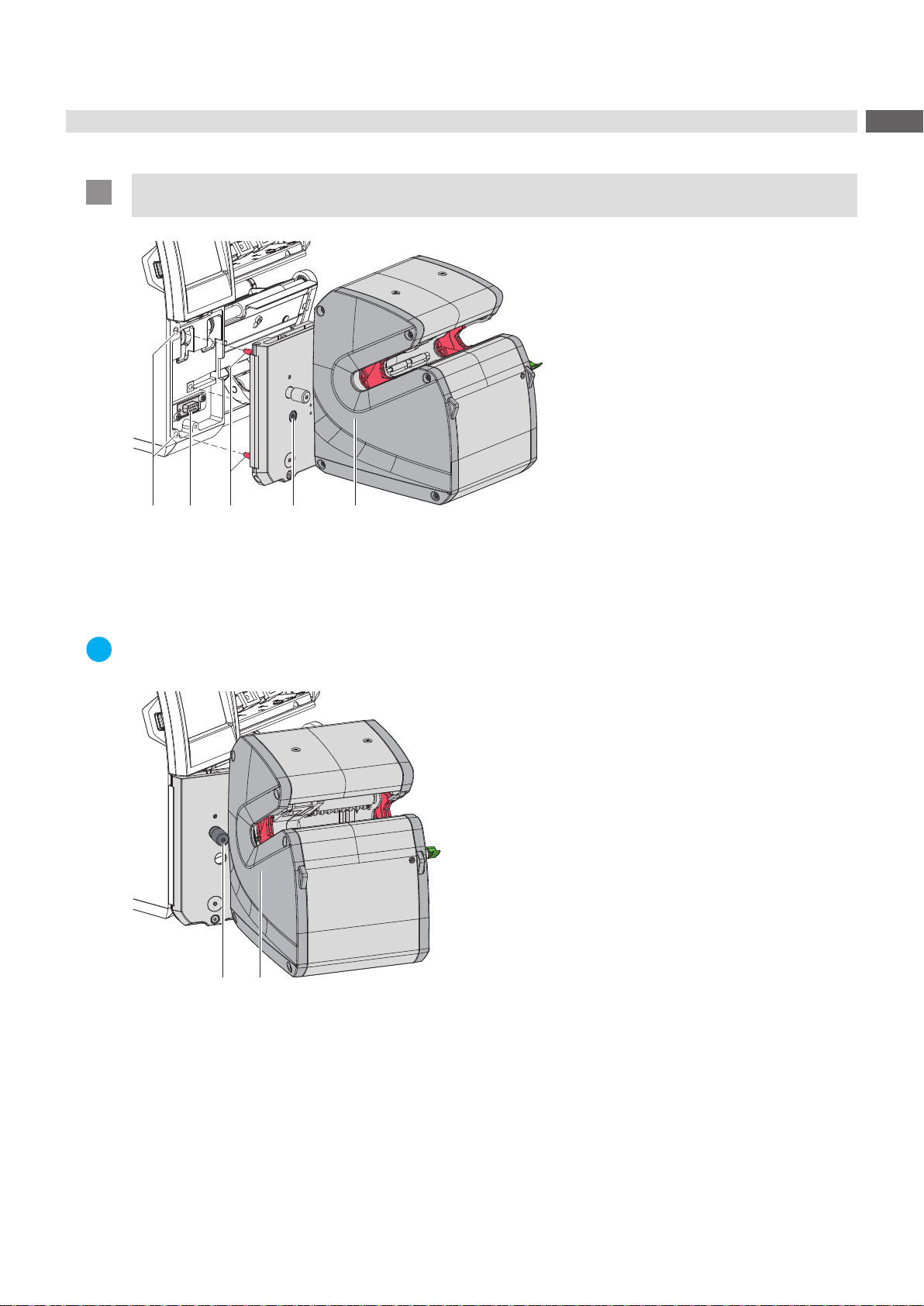

2.2 Mounting the Applicator............................................................................................................................9

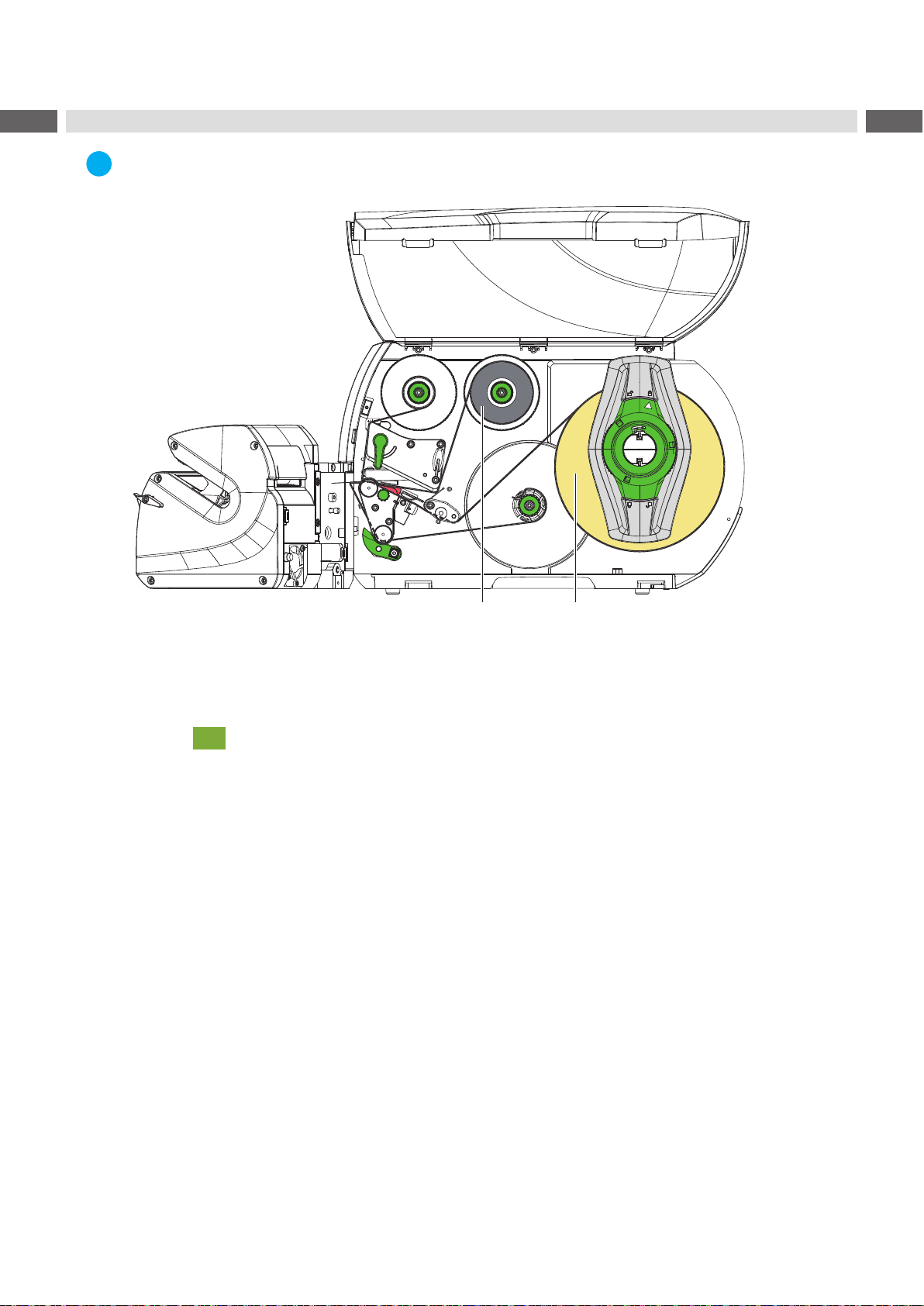

3 Loading Materials.................................................................................................................................10

4 Settings................................................................................................................................................. 11

4.1 Setting the Lateral Position.....................................................................................................................11

4.2 Setting the Stop.......................................................................................................................................11

4.3 Setting the Parallelism of Labels and Products......................................................................................12

5 Operation..............................................................................................................................................13

6 Conguration........................................................................................................................................14

6.1 Settings of the Printer Menu...................................................................................................................14

6.2 Special JScript Commands....................................................................................................................15

7 Fault Correction ...................................................................................................................................16

8 Approvals..............................................................................................................................................17

8.1 Reference to the EU Declaration of Conformity.....................................................................................17

8.2 FCC........................................................................................................................................................17