2-001 Safety Information

- It is the responsibility of the machine owner or their authorized representative to make certain that the machine

operators are correctly trained in the operation of the machine.

- Only authorized electricians or electrical specialists may work on the electrical equipment.

- The pneumatic and electric connecting lines are to be installed in an orderly manner and are to be protected from

damage (by cable channels, conduits, or something similar).

- The safety devices, which are included in this shipment, must always be utilized and shall not be by-passed or

rendered inoperable.

- During service or maintenance work, the machine must be turned off at the main electrical switch (unplug the

machine) and the machine must be disconnected from the pneumatic lines (for example, by quick coupling).

- Before a tool change, gearbox change or work in the area of the drill, the main switch must always be set at 0.

- Use only tools which meet specifications and regulations and which are strong and durable (such as the tools from

the Grass product line program).

-Only hard metals, or HSS (high speed steel) drills with a total length of 57 mm and a shaft diameter of 10 m may

be utilized.

- The drill diameter may be a maximum of 35 mm on the drive spindle and a maximum of 15 mm diameter on all

the other bore spindles.

- Before operating the machine, all safety devices must be checked to make sure they are complete and function

correctly.

- The operator should be especially careful with larger workpieces that project out over the machine. We strongly

recommend using a larger support base or additional support bases for the workpiece.

- Shavings should not be blown off, but should be suctioned with the appropriate device.

- The machine should always be turned off at the main switch when work is finished and then secured, so that

unauthorized persons cannot start it.

- Keep the workplace and the surrounding area clean because messiness and an unorganized workplace increase

the risk of injury.

- Protect yourself from electrical shocks.

- Utilize the machine only in dry spaces and never leave the machine outside in the rain.

- Keep unauthorized persons away from the machine.

- Only one person shall operate the machine.

- When working, keep your hands away from the working area of the drill and the insertion die arm.

- Wear appropriate work clothing when operating the machine.

- Use a hair net with long hair and do not wear wide or floppy pieces of clothing which could

become caught in moving machine parts.

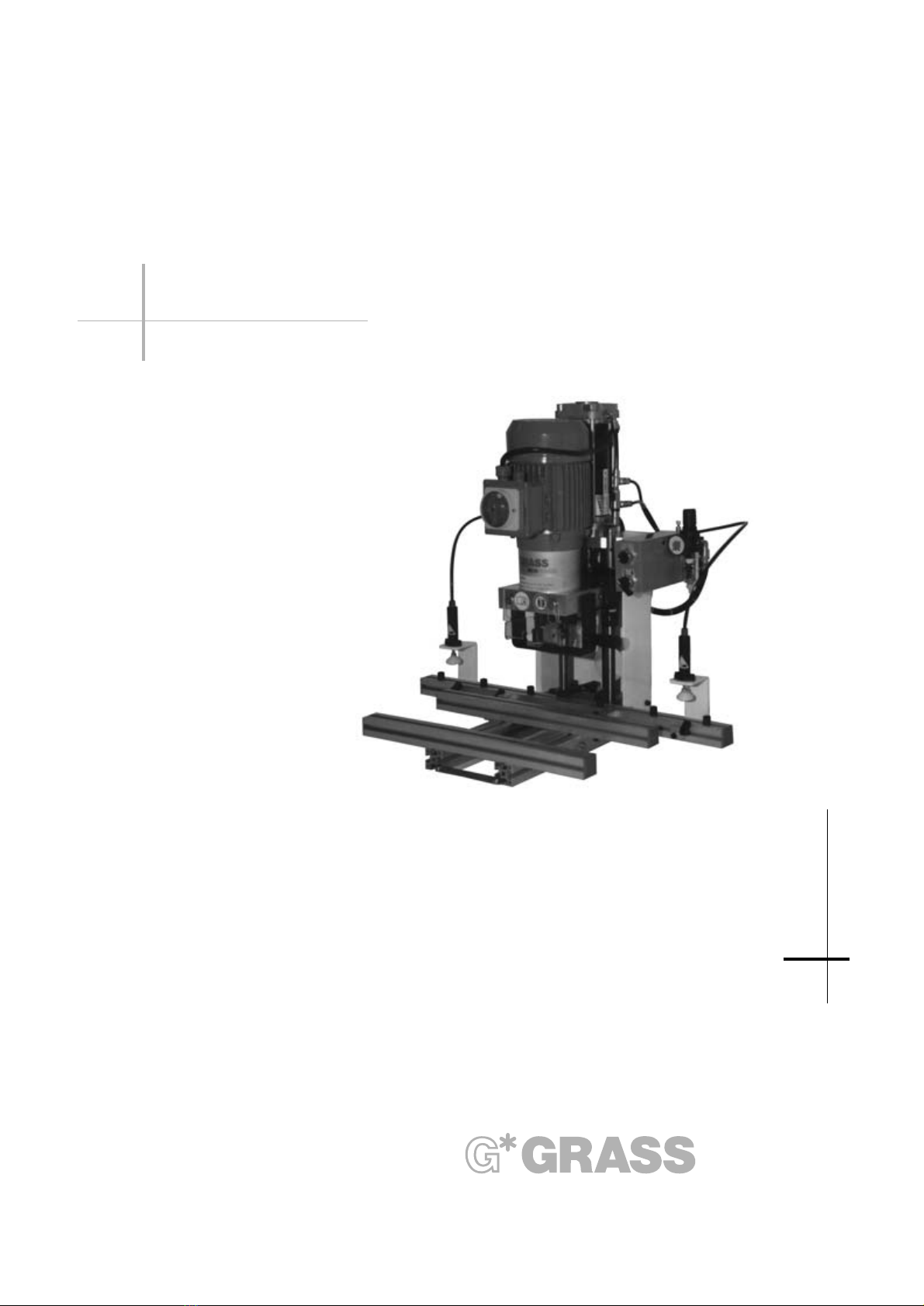

2-002 Recommended Usage

- The Grass Ecopress hinge drilling machine is used exclusively for drilling in solid wood and derived wood materi

als as well as for the purposes described in chapter 7-4 ”Examples of Usage”. Other uses are not specified,

and, thus, the manufacturer is not liable for resulting damages. The operator and user alone assume all risks.

- The operator must conform to the operating instructions when determining appropriate usages.

- The machine shall only be operated, serviced and maintained by trained and authorized personnel

- The original set-up may not be modified without the express consent of Grass GmbH.