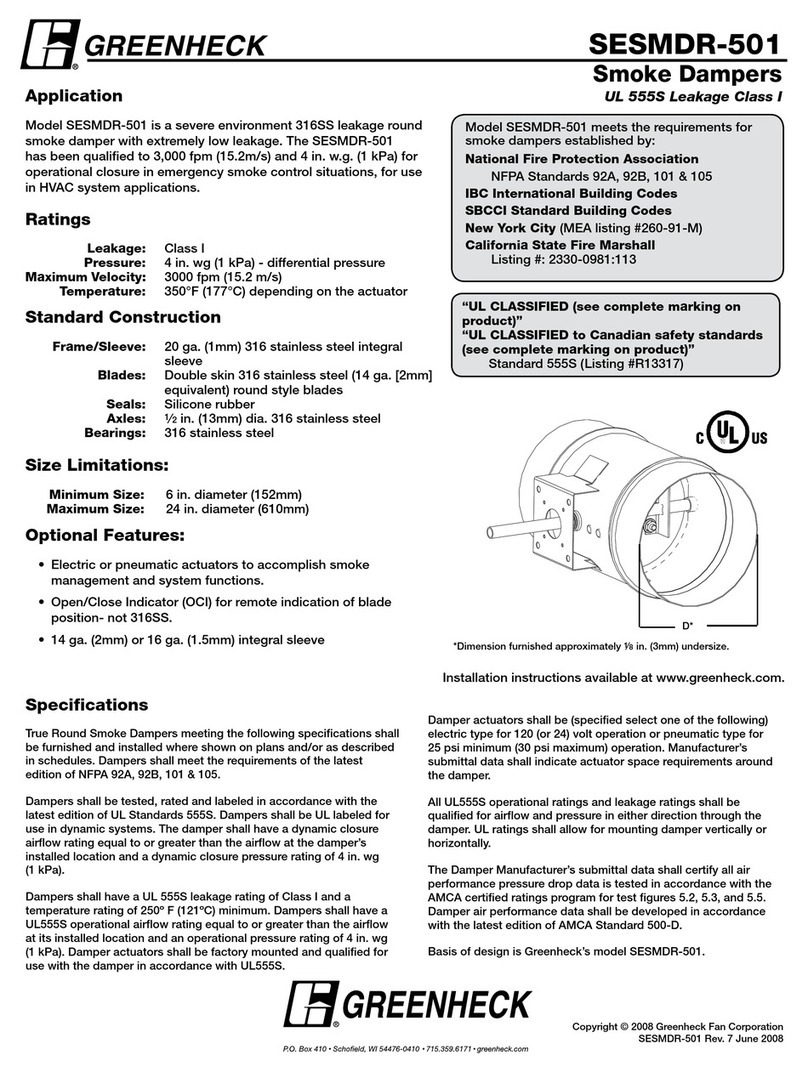

* Dimensions furnished approximately 1/8 in. (3mm) undersize.

D*

Model SSFSDR-512 meets the requirements for

fire dampers, smoke dampers and combination fire

smoke dampers established by:

National Fire Protection Association

NFPA Standards 80, 90A, 92A, 92B, 101 & 105

IBC International Building Codes

New York City (MEA listing #260-91-M)

California State Fire Marshall

Listing #: 3225-0981:112 (fire)

Listing #: 3230-0981:113 (smoke)

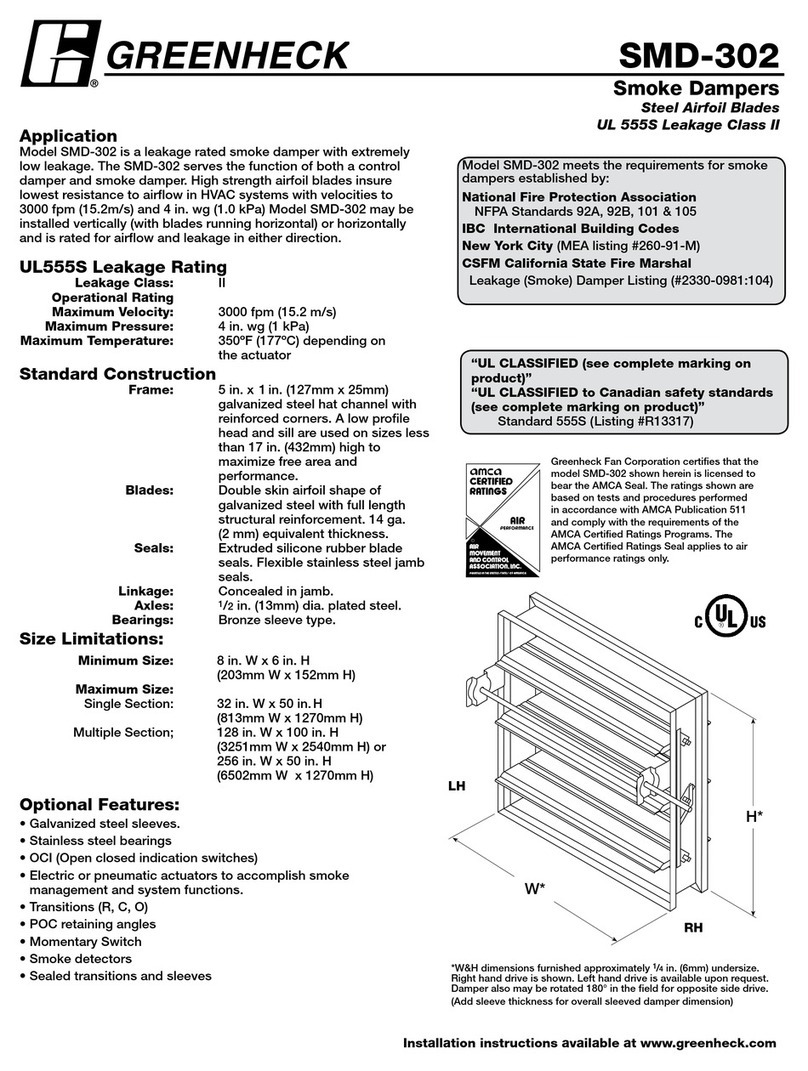

Application

Model SSFSDR-512 is a combination fire smoke damper constructed

out of 304 stainless steel with 3 round style blade. The SSFSDR-512

has been qualified to 3000 fpm (15.2 m/s) and 4 in. wg (1 kPa) for

operation and dynamic closure in emergency fire smoke situations.

Model SSFSDR-512 may be installed vertically (with blades running

horizontal) or horizontally and is rated for airflow and leakage in

either direction.

Ratings

UL 555 Fire Resistance Rating

Fire Rating: 1 1/2 Hour

Dynamic Closure Rating: Actual ratings are size dependant

Maximum Velocity: 3000 fpm (15.2 m/s)

Maximum Pressure: 4 in. wg (1 kPa)

UL 555S Leakage Rating

Leakage Class: II

Operational Rating: Actual ratings are actuator dependant

Maximum Velocity: 3000 fpm (15.2 m/s)

Maximum Pressure: 4 in. wg (1 kPa)

Maximum Temperature: 350º F (177°C) —Depending on actuator

Standard Construction

Frame/Sleeve: 20 ga. (1mm) 304 stainless steel round

integral sleeve

Blades: Double skin 304 stainless steel (14 ga.

[2mm] equivalent) round style blades

Seals: Extruded silicone rubber blade seals

Linkage: 304 stainless steel - concealed in jamb.

Axles: 1/2 in. (13mm) dia. 304 stainless steel.

Bearings: 304 stainless steel sleeve type

Fusible Link: UL listed 165ºF (74ºC) -not 304SS

Size Limitations

Minimum Size: 6 in. (152mm) diameter

Maximum Size: 24 in. (610mm) diameter

Optional Features

•OCI(Openclosedindicationswitches)-not304SS

•165ºF(74°C),212ºF(100°C),and350ºF(177°C)RRLavailable

- not 304SS.

•TOR(remoteoverrideof165ºF(74°C)closureallowsdamperto

perform smoke management functions during a fire emergency)

- not 304SS.

•Electricorpneumaticactuatorstoaccomplishsmokemanagement

and system functions.

•Oneretainerplaterequired,additionalretainerplateavailable.

•14ga.(2mm)or16ga.(1.5mm)frame/sleeve

SSFSDR-512

Combination Fire Smoke Dampers

Round Stainless Steel Blade

UL 555S Leakage Class II

UL555 1 1/2 Hour Fire Resistance Rating

“UL CLASSIFIED (see complete marking on

product)”

“UL CLASSIFIED to Canadian safety standards

(see complete marking on product)”

Standard 555 (Listing #R13317)

Standard 555S (Listing #R13447)

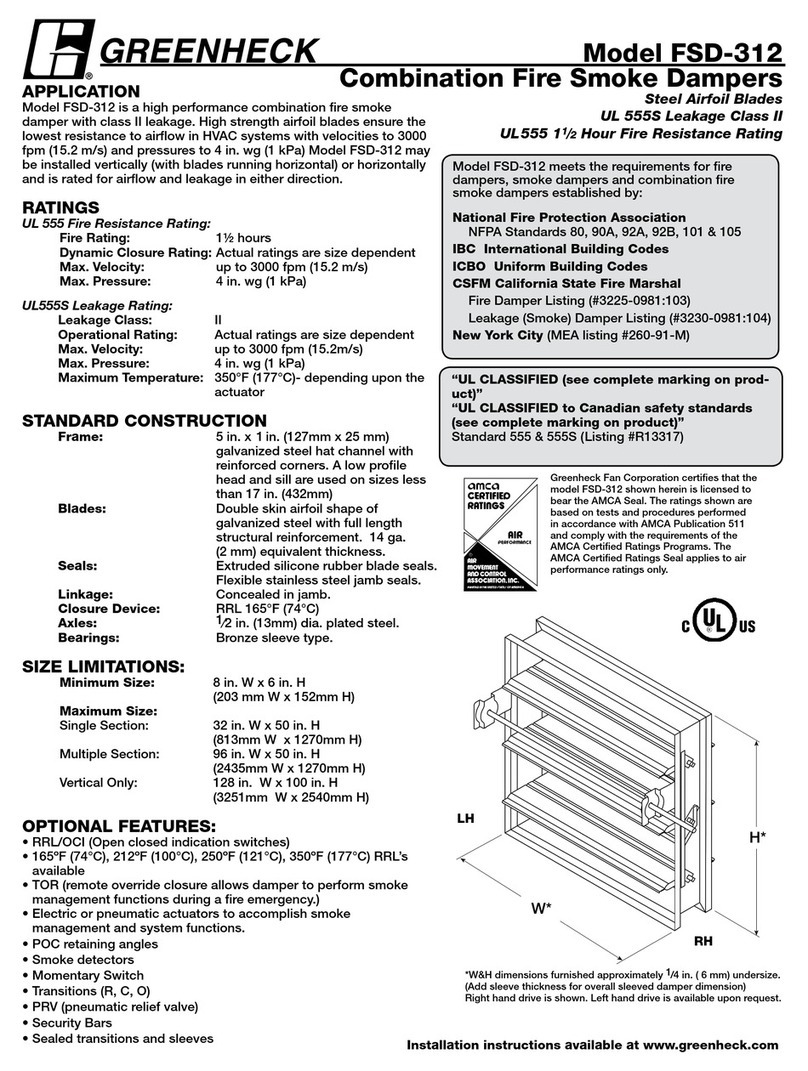

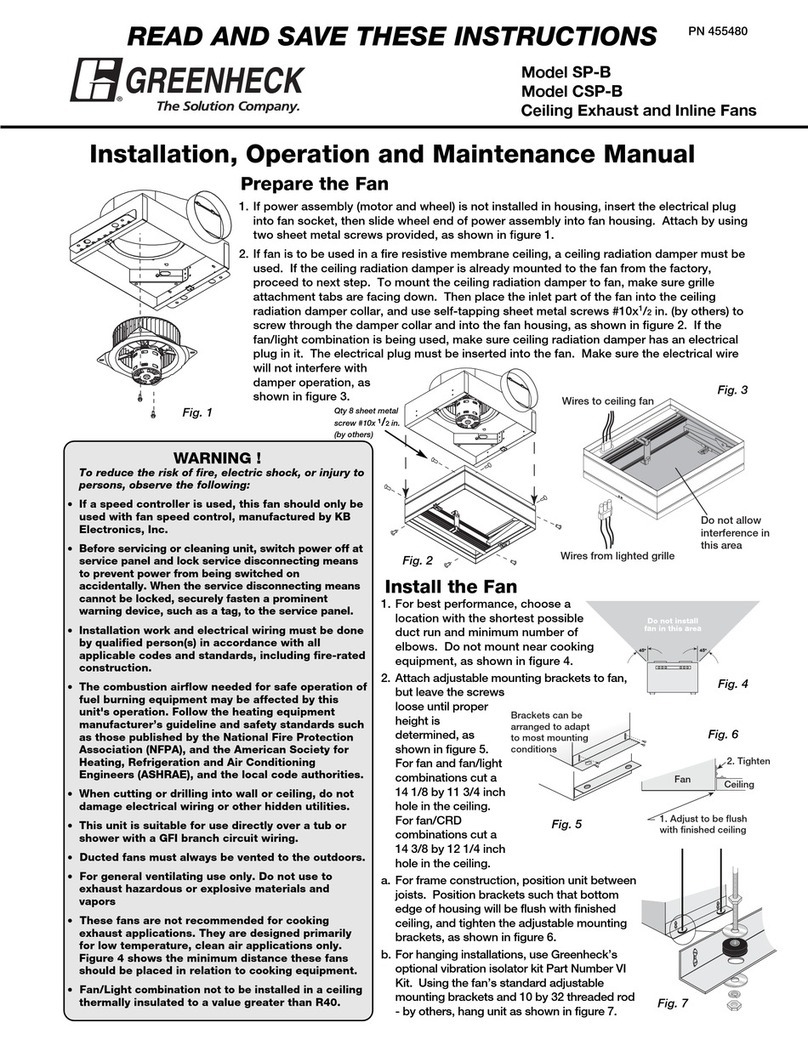

Opening + 2 in. Min.

1.00 in. Min. Typ.

Fasteners

Clamping

Screw

Nut

Retaining

Plate Assembly

Clamping Screw

Minimum Wall/Floor Opening

= Nominal Dia. + 7/8 in.

Opening + 2 in. Min.

1.00 in. Min. Typ.

Fasteners

Clamping

Screw

Nut

Retaining

Plate Assembly

Clamping Screw

Minimum Wall/Floor Opening

= Nominal Dia. + 7/8 in.

Installation instructions available at www.greenheck.com.