INSTALLATION, OPERATION AND MAINTENANCE MANUAL

**WARNING**

DISCONNECT ALL ELECTRICAL POWER TO THE ERM PRIOR TO INSPECTION OR SERVICING.

FAILURE TO COMPLY WITH THIS SAFETY PRECAUTION COULD RESULT IN SERIOUS INJURY OR DEATH.

READ AND SAVE THESE INSTRUCTIONS

INSTALLATION

Greenheck Energy Recovery Modules (ERM) are thoroughly inspected

and test run at the factory, however damage may occur during handling

and shipping. Consequently, it is important to inspect the unit for visible

and concealed damage before beginning installation. Report any

damage to the shipper immediately. Turn the wheel by hand (clockwise

as viewed from the pulley side) to verify the wheel rotates freely. In

addition, assure all accessory items are present.

ELECTRICAL CONNECTIONS

The electrical supply must be compatible with that shown on the wheel

drive motor nameplate: voltage, phase, and amperage capacity (see

page 2 for specific requirements). Units are supplied with a receptacle

for the cassette plug and service box for wiring. Connect the ERM

wiring directly to blower wiring or to blower fan relay to assure power to

the ERM whenever fan is in operation. All wiring must be properly fused

and conform to local and national electrical codes.

DO NOT OPERATE THE ERM FOR ANY EXTENDED PERIOD WITHOUT

AIRFLOW ACROSS THE ENERGY WHEEL AS THE DRIVE MOTOR IS

COOLED BY THE AIRFLOW.

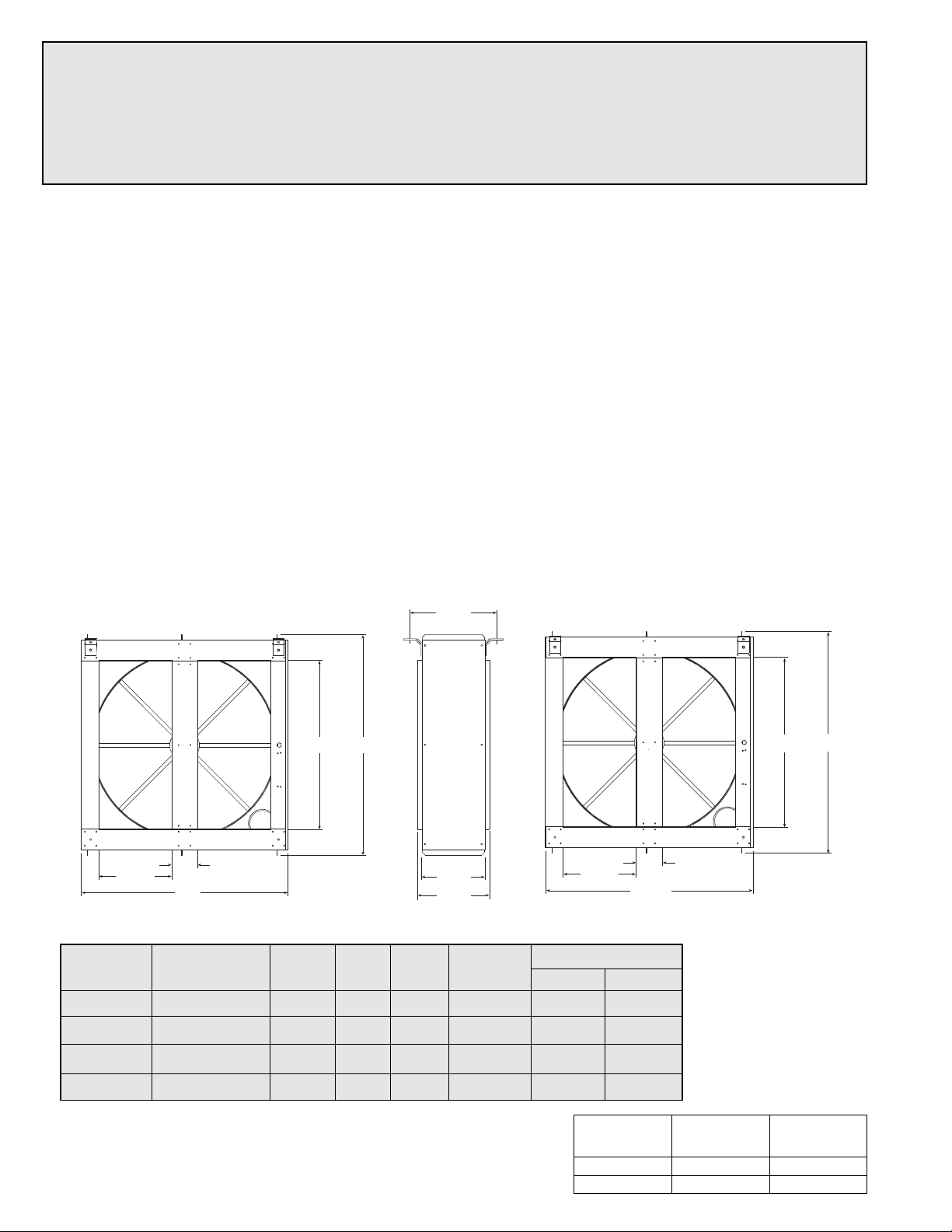

MOUNTING

The ERM is shipped with a mounting kit, which contains four hanging brackets, fasteners and a separate instruction sheet with

parts list. These brackets will support the ERM in either the vertical or horizontal position for design flexibility. A 3/8"x3/4" hex

head bolt is located at each corner of the ERM for attaching these brackets. To hang

the ERM:

Note: To reduce unit weight for handling purposes, the cassette may be removed from

the cabinet (reduces ERM-36 from 155 lbs. to 75 lbs., reduces ERM-52 from 280 lbs. to

110 lbs.).

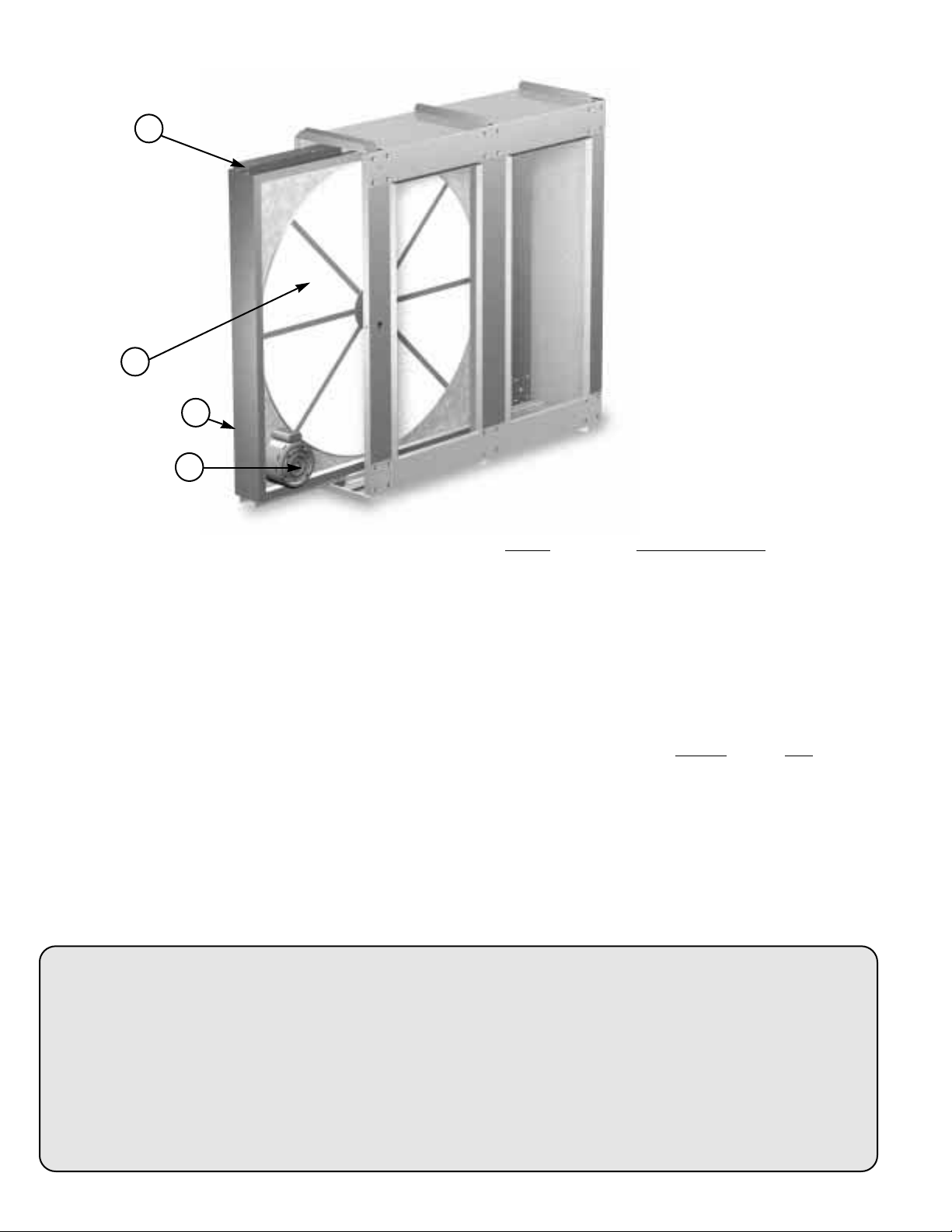

1. To remove the cassette from the cabinet, remove the access panel and unplug the

wheel drive motor at the electrical receptacle in the cabinet.

2. Replace the access panel before mounting to insure squareness.

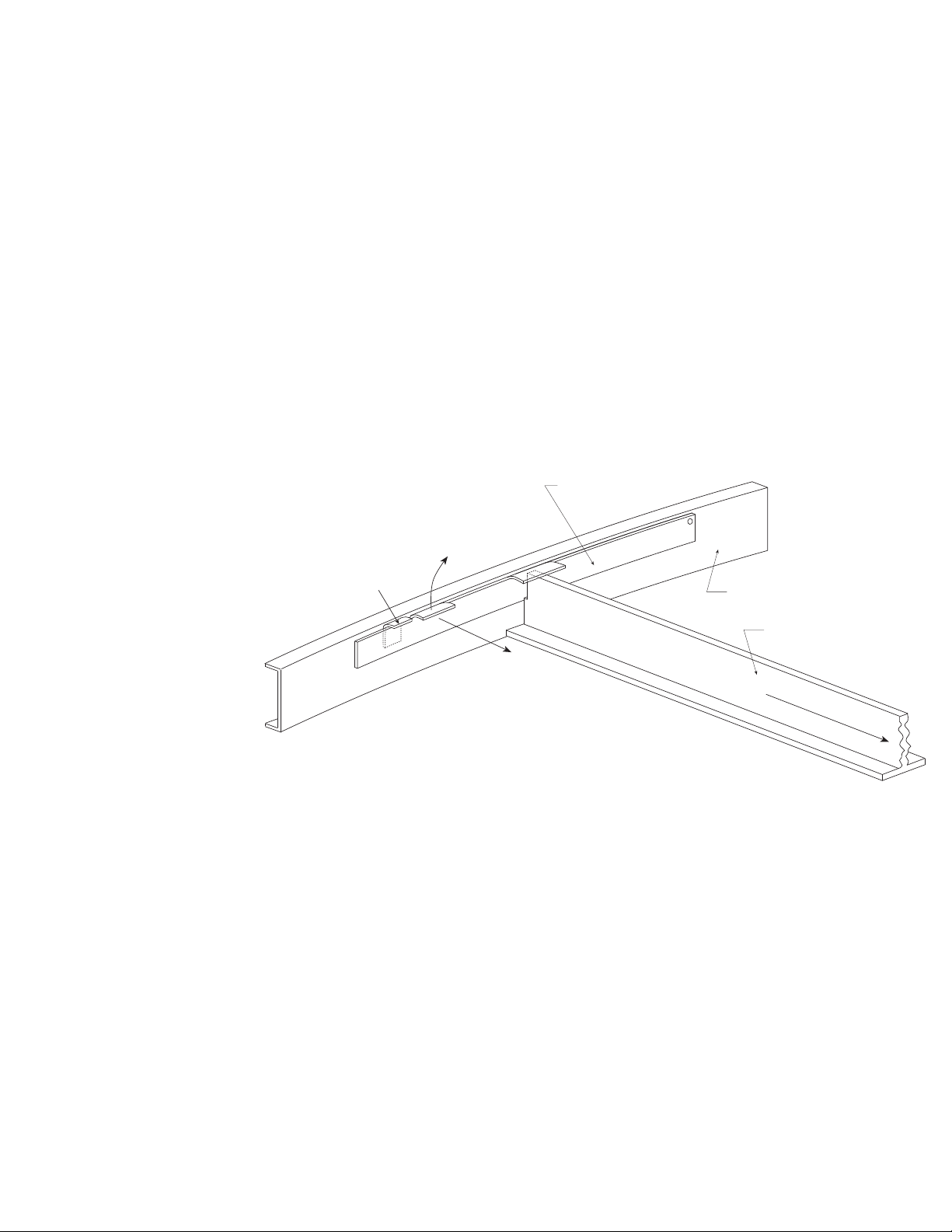

3. Remove the appropriate four bolts from the ERM and use to

secure the brackets as shown in Figure 1. These brackets are

designed for 3/8" threaded hanging rods.

4. To reinstall the cassette in the mounted ERM cabinet, align

the cassette sliders with the channels in the cabinet and slide

the cassette in place. Replace access panel when finished.

IMPORTANT: ERM MUST BE INSTALLED SUCH THAT THE

ENERGY WHEEL CASSETTE SLIDES IN AND OUT OF THE

CABINET PARALLEL TO THE FLOOR.

ENERGY RECOVERY MODULES

Models ERM-36 & 52

FIGURE 1

Part # 456785