Part Number 462101

Installation Instruction Supplement

Refer to:

‘Installation Instructions for FD, DFD, SSFD, & KFD

Models’ (Part Number 452763)

or

‘Installation Instructions for FSD-XXX, DFD-XXX, CFSD-

XXX, & SSFSD-XXX Series Fire & Combination Fire

Smoke Dampers’ (Part Number 461336)

or

‘Installation Instructions for FD & DFD 150X Series

Curtain Fire Dampers’ (Part Number 453946) for

additional details.

Metal Stud Framing for Fire Dampers in

Drywall Partitions Utilizing One Retaining

Angle

FD & DFD Series

1½ Hour Curtain Fire Dampers and

FSD Series

1½ Hour Combination Fire Smoke Dampers

Vertical Mount

“UL Classified (see complete marking on

product)”

“UL Classified to Canadian safety standards (see

complete marking on product)”

Standards UL555 & UL555S

Classifications filed at UL under Listing R13317

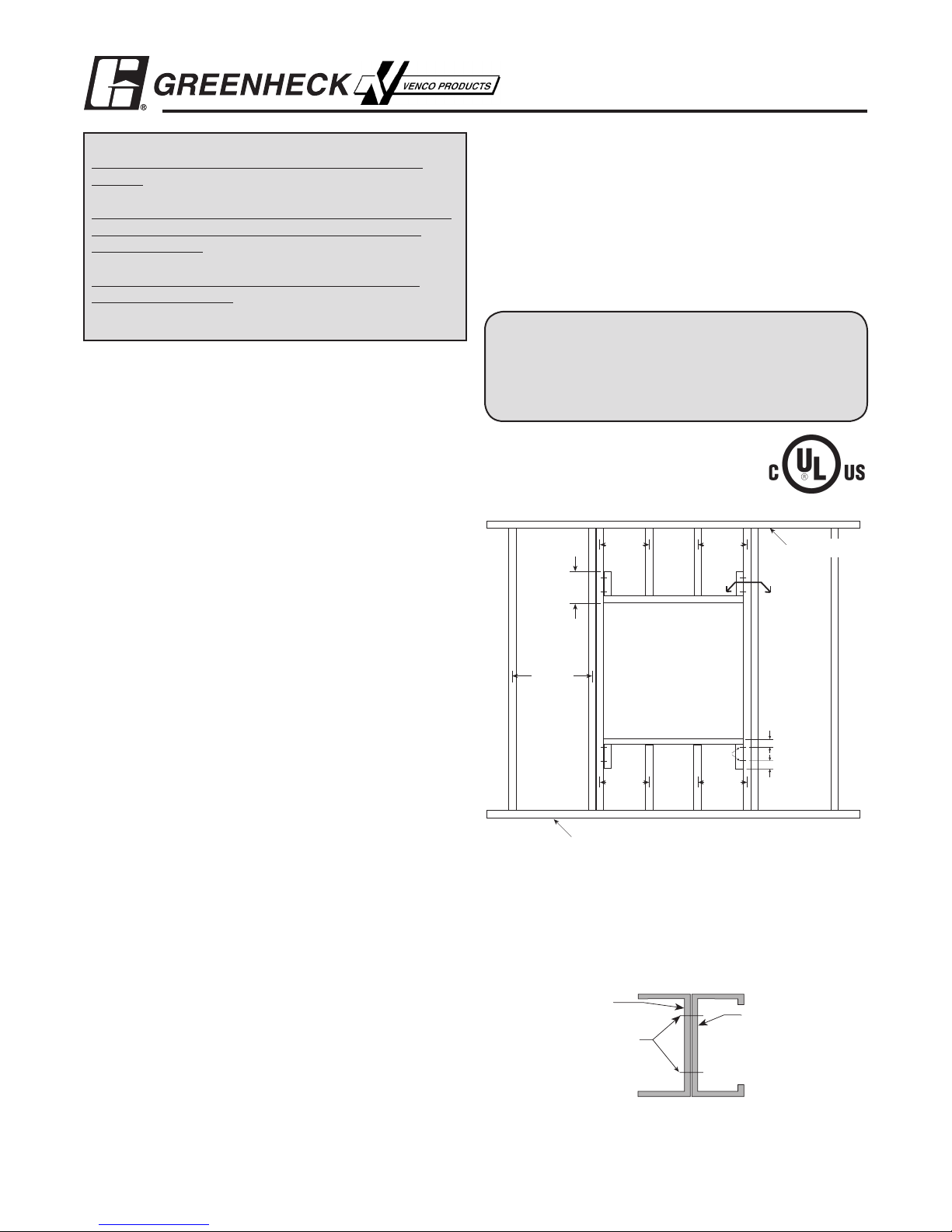

Notes

1.Gypsum panels must be screwed 12 in. (305mm)

on center maximum to all stud and runner flanges

surrounding opening. (See Figure 1 and Figure 2).

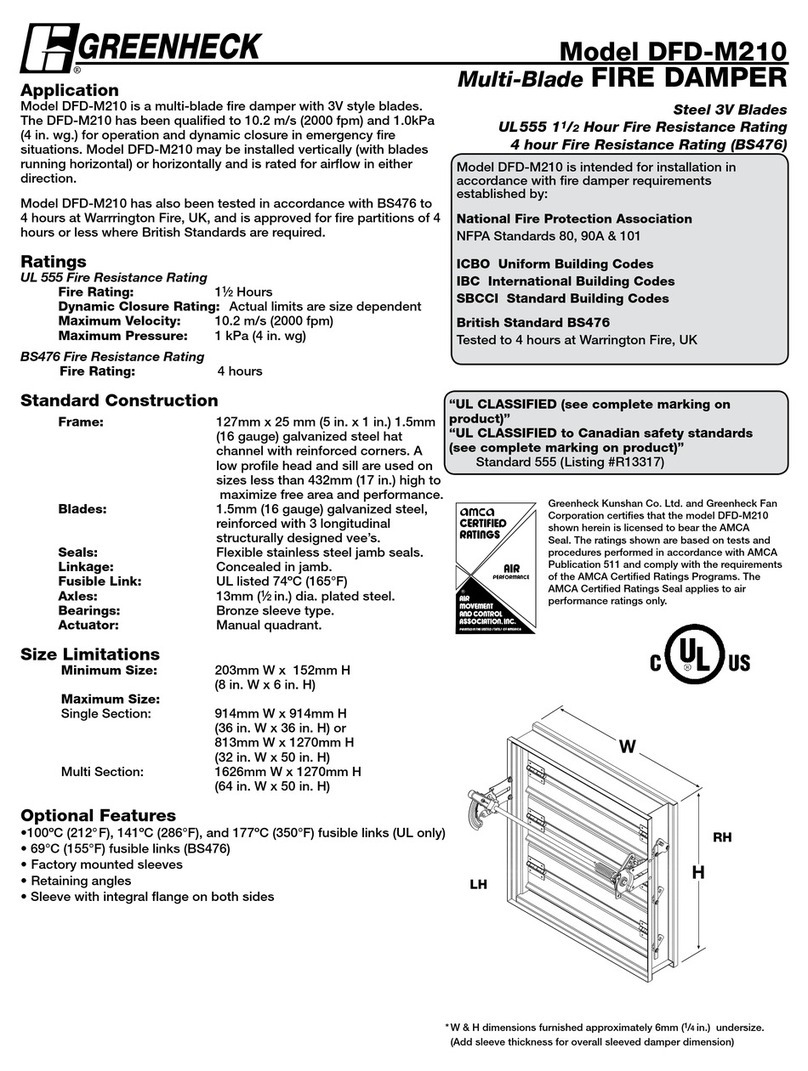

2.Fire damper and sleeve assemblies 80 in. W x 50 in. H

(2032mm x 1270mm), 50 in. W x 80 in. H (1270mm x

2032mm), or 40 in. W x 100 in. H (1016mm x 2540mm)

and smaller only require retaining angles on one side

of the partition (See Figure 3 and Figure 4). Retaining

angles must be attached to the sleeve and the partition.

Larger damper assemblies require retaining angles on

both side of the partition. Retaining angles must be

attached to the sleeve.

• Retaining angles must be a minimum of 16 gauge

(1.5mm) steel and have a minimum of 1½ in. x 1½ in.

(38mm x 38mm) legs.

• Retaining angles must be attached to the sleeve using

one of the methods shown below:

• tack or spot welds

• #10 sheet metal screws and bolts

• Retaining angles must be attached to the partition using

drywall screws of a length such that the screw engages

the stud/track by a minimum of ½ in. (13mm).

• A minimum of two connections per side, top, and bottom,

12 in. (305mm) on center maximum for openings of

48 in. W x 36 in. H (1219mm x 914mm) and less, and 6 in.

(152mm) on center for openings 80 in. W x 50 in. H

(2032mm x 1270mm), 50 in. W x 80 in. H (1270mm x

2032mm), or 40 in. W x 100 in. H (1016mm x 2540mm)

or less.

• Retaining angles must overlap the partition a minimum of

1 in. (25mm).

Grille Installations (Dampers up to 36 in. x 36 in.

[914mm x 914mm] maximum)

• Angle legs may be reversed and one leg inserted into the

wall/floor opening. Retaining angles used in conjunction

with grille installations must be a minimum of 16 gauge

(1.5mm) steel and have a minimum of 5/8 in. x 1 in.

(15mm x 25mm) of sleeve into the studs. Space screws a

maximum of 6 in. (152mm) on center and a maximum of

2 in. (51mm) from the corners (minimum of 2 screws per

side). See Figure 5 and Figure 6.

Note: Screws used to attach grille are allowed to penetrate

reversed angle leg.

2

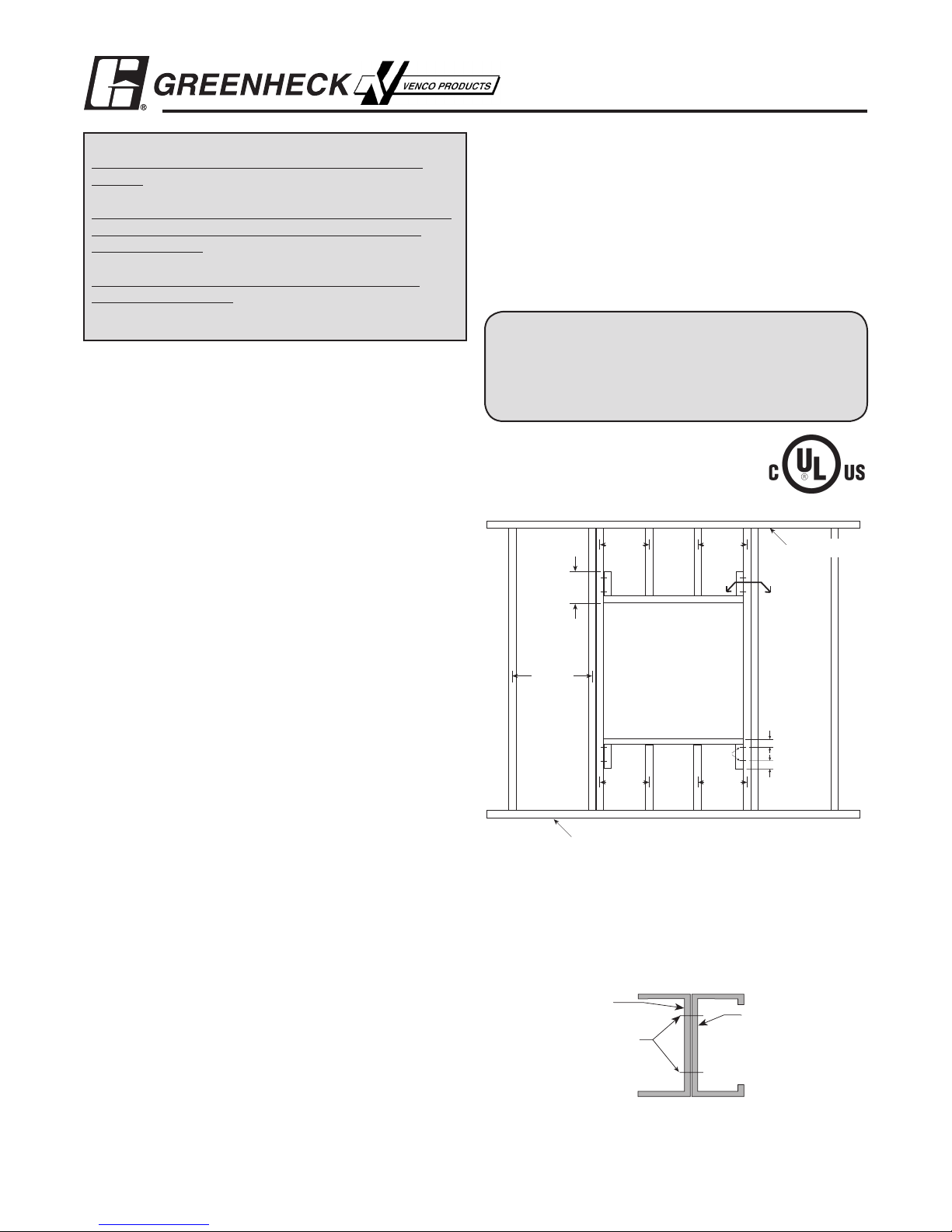

1⁄2in. Min.

Runner

Screws

2

1⁄2in.

Min. Stud

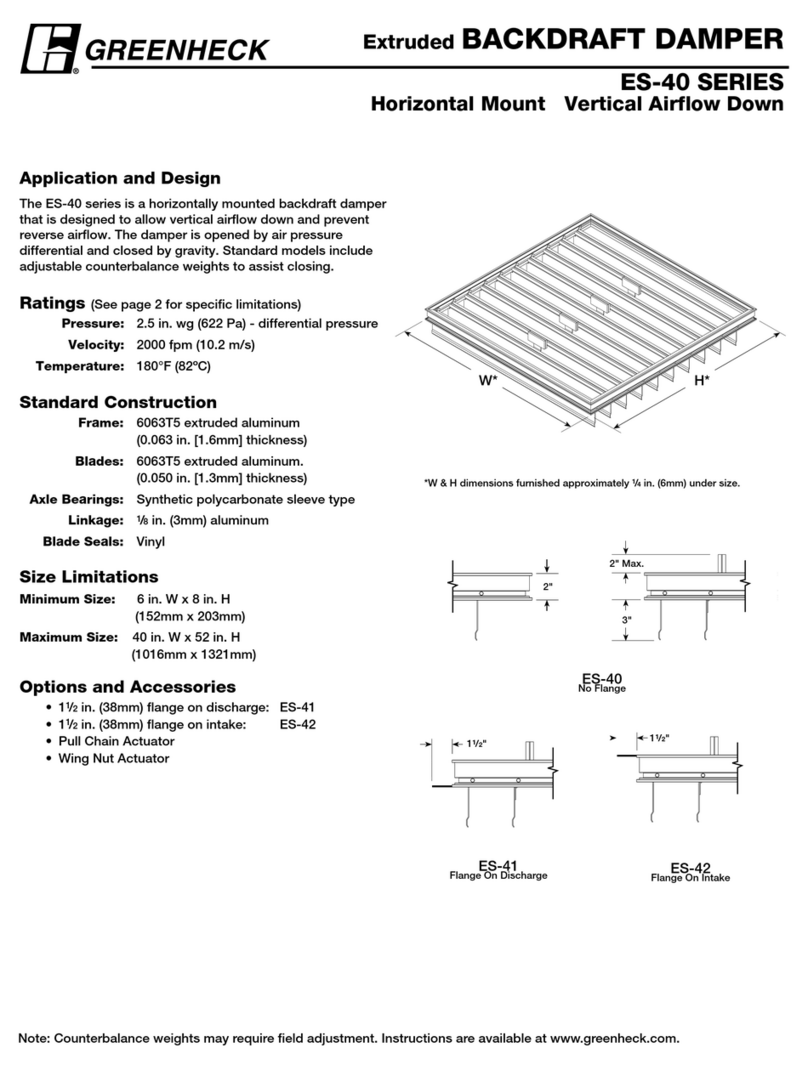

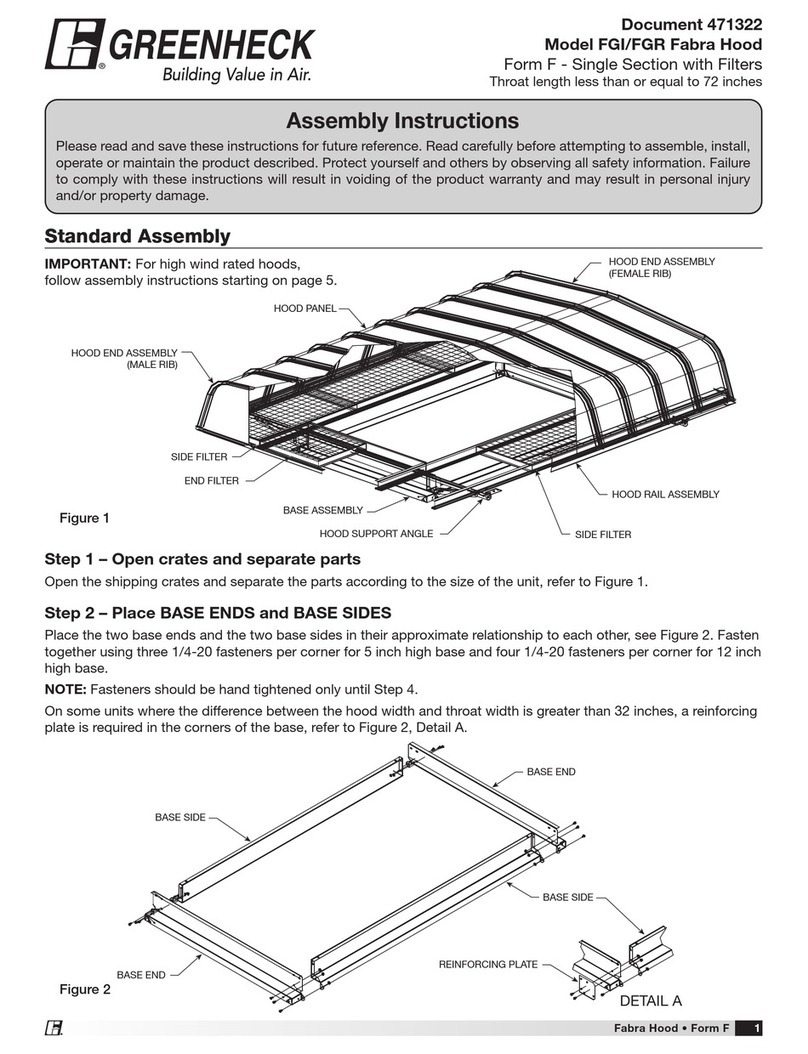

Figure 2: Section A-A

12 in.

24 in. o.c.

Maximum

Floor Runner

2 in.

Ceiling Runner

2 Panhead

Screws

24 in. o.c.

Maximum

(metal studs)

24 in. o.c.

Maximum

(metal studs)

16 in. o.c.

Maximum

(wood studs)

16 in. o.c.

Maximum

(wood studs)

2 in.

See Section A-A

Figure 1: Opening Preparation Detail (Double

vertical studs are not required for openings 36 in. x

36 in. (914mm x 914mm) or smaller.