Greenlee GATOR EK06FT User manual

Other Greenlee Crimping Tools manuals

Greenlee

Greenlee UAP32GL GATOR User manual

Greenlee

Greenlee K28GL User manual

Greenlee

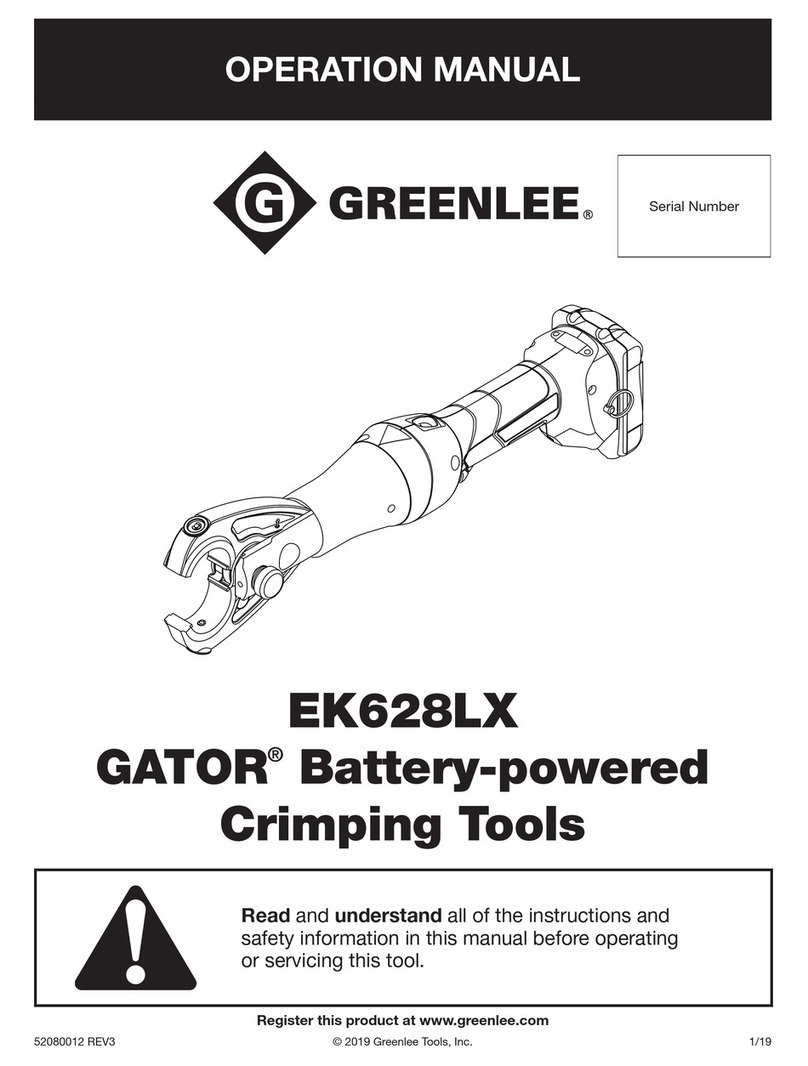

Greenlee GATOR EK628LX User manual

Greenlee

Greenlee EK6ATLX User manual

Greenlee

Greenlee K2-1BGL User manual

Greenlee

Greenlee RK06AT User manual

Greenlee

Greenlee GATOR EK410 User manual

Greenlee

Greenlee Quick Draw 7804SB User manual

Greenlee

Greenlee GATOR EK6IDCVX User manual

Greenlee

Greenlee GATOR EK06AT User manual

Greenlee

Greenlee GTS-1930 User manual

Greenlee

Greenlee GATOR EK1240K User manual

Greenlee

Greenlee K05-Syncro User manual

Greenlee

Greenlee GATOR EK1240 User manual

Greenlee

Greenlee 1990 User manual

Greenlee

Greenlee GATOR GREEK628LX11 User manual

Greenlee

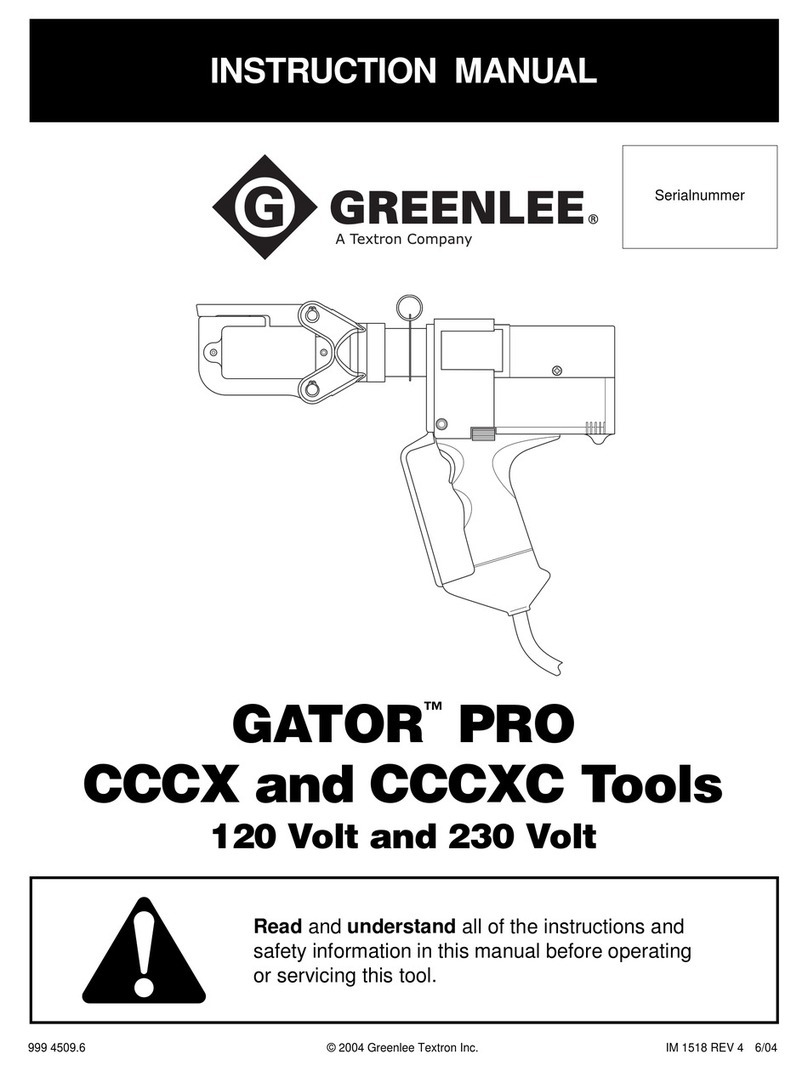

Greenlee CCCX User manual

Greenlee

Greenlee GATOR RK425 User manual

Greenlee

Greenlee LPK1240K User manual

Greenlee

Greenlee E12CCXLX User manual

Popular Crimping Tools manuals by other brands

Tyco Electronics

Tyco Electronics 90035-3 instruction sheet

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual