Greenlee GATOR ESG85GL User manual

Other Greenlee Cutter manuals

Greenlee

Greenlee GATOR ES32 User manual

Greenlee

Greenlee GATOR ESG45GL User manual

Greenlee

Greenlee GATOR Plus ESG45GL User manual

Greenlee

Greenlee 645-11/16 User manual

Greenlee

Greenlee 625-3/4 User manual

Greenlee

Greenlee EBS12ML User manual

Greenlee

Greenlee 756 User manual

Greenlee

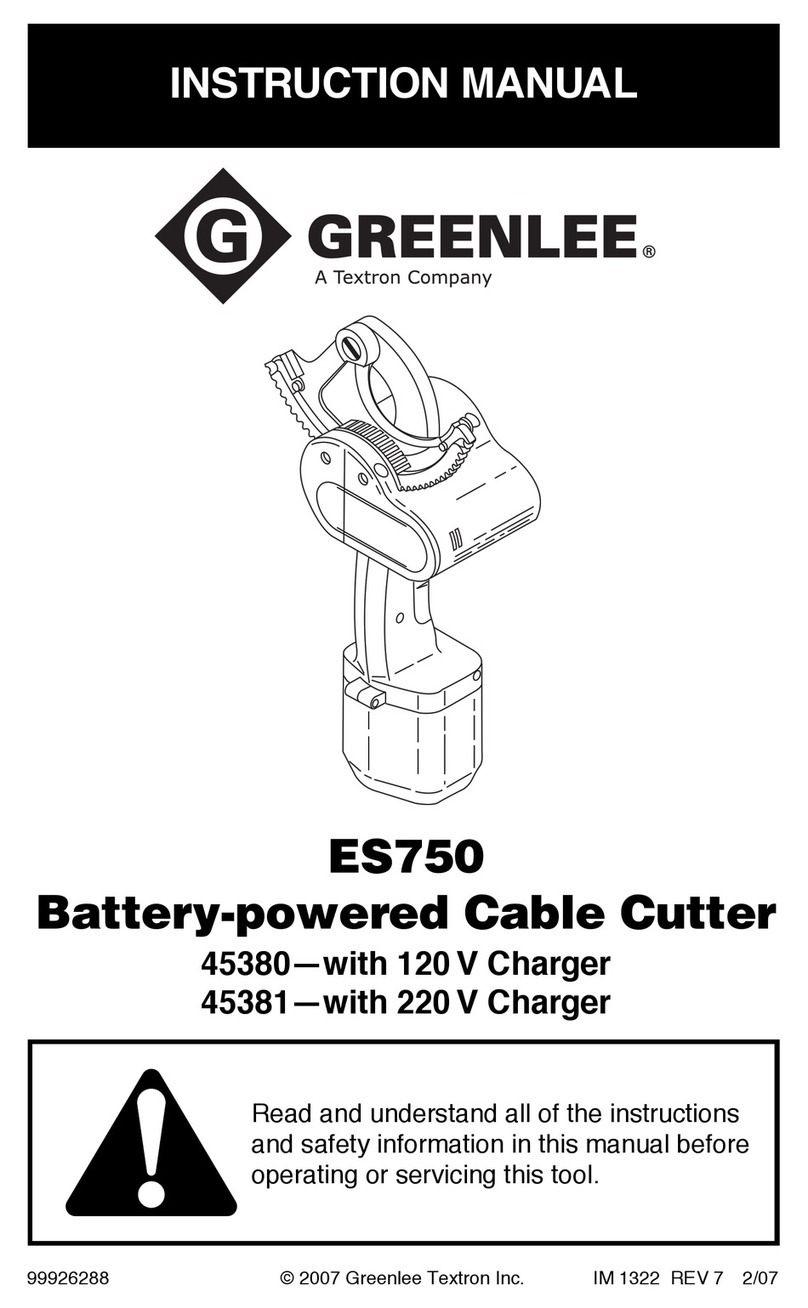

Greenlee ES750 User manual

Greenlee

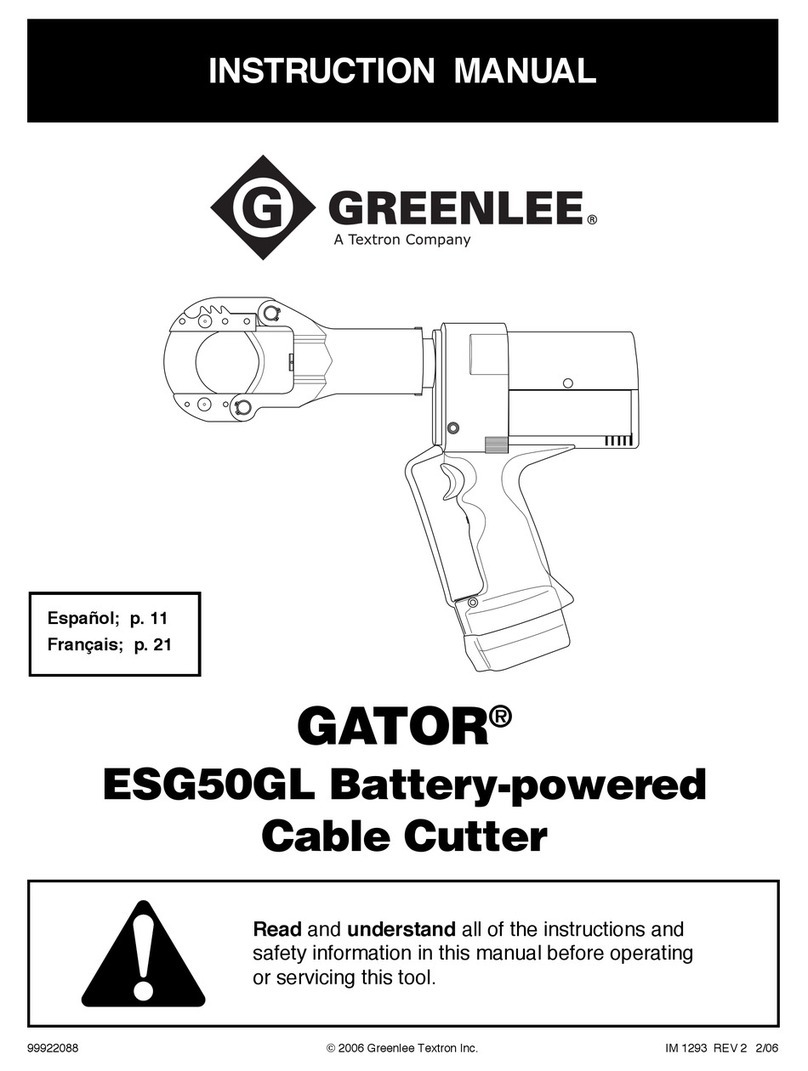

Greenlee GATOR ESG50GL User manual

Greenlee

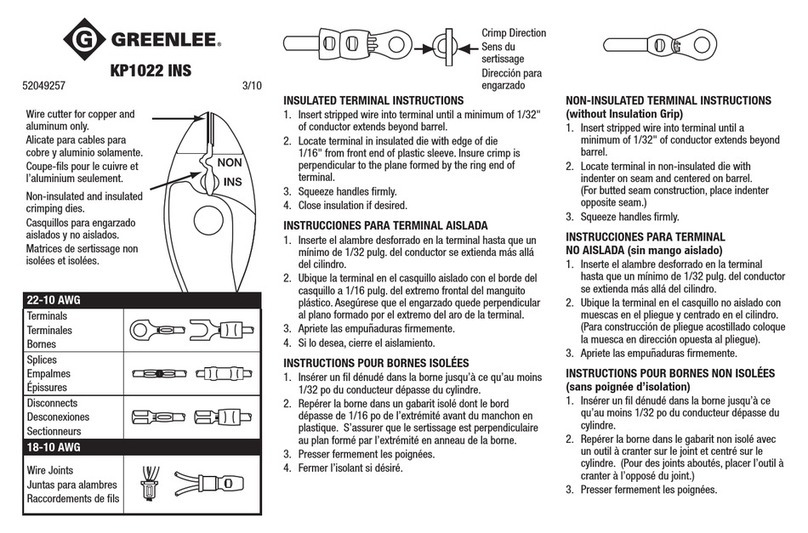

Greenlee KP1022 INS User manual

Greenlee

Greenlee SDG45 User manual

Greenlee

Greenlee Shear 30T User manual

Greenlee

Greenlee ES20LXR User manual

Greenlee

Greenlee GATOR ESG55LX User manual

Greenlee

Greenlee 881 Cam Track User manual

Greenlee

Greenlee GATOR ESG45L User manual

Greenlee

Greenlee C3 Auto Whip Clad Cable Cutter User manual

Greenlee

Greenlee Gator ES20HVX User manual

Greenlee

Greenlee GATOR EK425LXCJACSR User manual

Greenlee

Greenlee 645-3/4 User manual

Popular Cutter manuals by other brands

Milwaukee

Milwaukee HEAVY DUTY M12 FCOT Original instructions

SignWarehouse.com

SignWarehouse.com Bobcat BA-60 user manual

Makita

Makita 4112HS instruction manual

GEISMAR STUMEC

GEISMAR STUMEC MTZ 350S manual

Hitachi

Hitachi CM 4SB2 Safety instructions and instruction manual

Dexter Laundry

Dexter Laundry 800ETC1-20030.1 instruction manual