Page 10

11. BALANCING THE UNIT (RNC 1.5, RNC 2.0 & RNC 2.0ES ONLY)

TOOLS REQUIRED TO

BALANCE THE HRV/ERV

•

A Magnehelic gauge capable of

measuring 0 to 2.0 inch of water (0 to

500 Pa) and two (2) plastic hoses.

• A balancing reference chart located

on the HRV/ERV access door panel.

CONSIDERATION WHEN

BALANCING THE HRV/ERV

• Seal all the unit ductwork with tape.

Close all windows and doors.

•

Insure all exhaust devices such as range

hood, dryer and bathroom fans are OFF.

• Make sure that all filters are clean

and that there is no obstruction in

ductwork

• Make sure that the forced air system

blower is “ON” when connected to an

existing forced air system ductwork.

•

If it is a direct duct system installation

ensure forced air system blower is

“OFF”.

USING THE DUOTROL

SELECTOR SWITCH

When on Balancing Mode, the Selector

Switch allows you to choose the motor

you want to set.

GREEN LIGHT

Mode Selector

A) Closed Duotrol Cover

1. INTER (Exhaust Motor)

2. CONT (Both Motors)

3. OFF (Supply Motor)

YELLOW LIGHT

Balancing Mode

B) Open Duotrol Cover

1. UP (Exhaust Motor)

2. MIDDLE (Both Motors)

3. DOWN (Supply Motor)

IMPORTANT: Insure the HRV/ERV has

completed the defrost sequence. That

the dehumidistat is deactivated by

turning the round dial to the “OFF”

position, the Range is” NORMAL”, the

mode is “CONT” and the Cycle per Hour

is set at “0/0”.

NOTE: The unit is considered balanced

even if there is a difference of ±10 cfm

(or ± 5 l/s or 17 m³/h) between the two

air flows

DUOTROL™ BALANCING SYSTEM PROCEDURES

Step 1: Place the Magnehelic gauge on a level surface and

adjust the needle to zero.

Step 2: Connect the two (2) plastic hoses to the gauge on

the HIGH & LOW pressure connections.

Step 3: Once the total ventilation requirements are

determined, you can start balancing the HRV/ERV.

(Refer to 1. Ventilation Requirements)

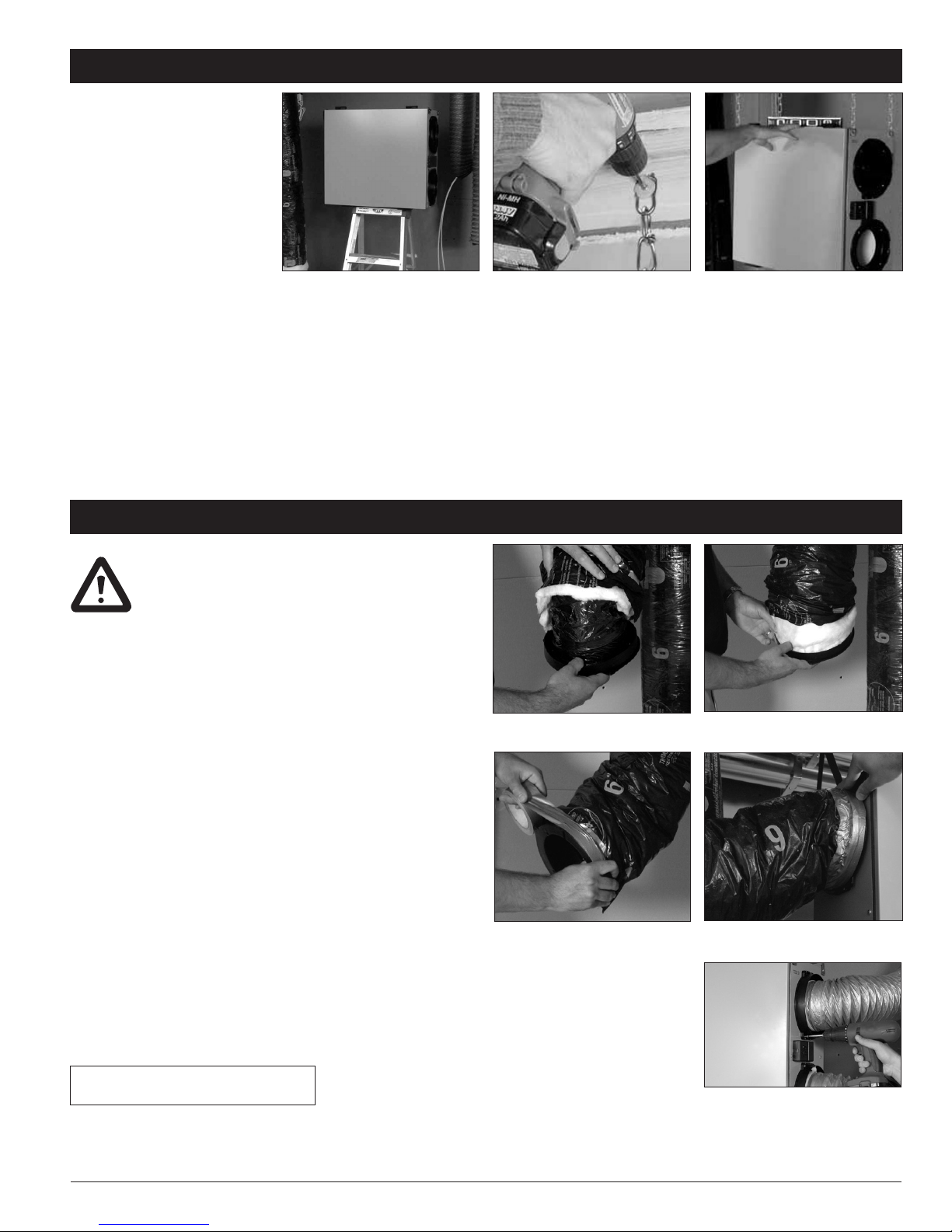

Step 4: Remove the (4) four nylon knock out seals located on

the HRV/ERV access door. (Ref fig 11.1)

Fig 11.1

Fresh Air

from Outside

Stale Air

to Outside

Stale Air

from Home

Fresh

Air

Stale

Air

Fresh Air

to Home

Remove all four (4)

nylon knock out seals.

Do not discard.

LOWLOW

LOW

LOW

HIGH

HIGH

HIGH

HIGH

Aspiration

d'air frais

Évacuation

d'air vicié

Aspiration

d'air vicié

Air frais

Air vicié

Distribution

d'air frais

BASBAS

BAS

BAS

HAUT

HAUT

HAUT

HAUT

Enlever les quatre (4)

bouchons de nylon.

Ne pas les jeter.

Pressure / Pression Fresh air / Air frais Stale air / Air vicié

IN. W.G. Pascal CFM L/s CFM L/s

PO. d’eau (Pa) PCM PCM

0.36 90 216 102 - -

0.34 85 209 99 222 105

0.32 80 200 94 214 101

0.30 75 192 91 207 98

0.28 70 183 86 198 93

0.26 65 173 82 189 89

0.24 60 163 77 180 85

0.22 55 153 72 170 80

0.20 50 142 67 159 75

0.18 45 131 62 148 70

0.16 40 119 56 136 64

0.14 35 107 50 124 59

0.12 30 95 45 111 52

0.10 25 82 39 97 46

0.08 20 68 32 83 39

0.06 15 55 26 69 33

0.04 10 55 26 54 25

Balancing chart 2.0Balancing chart 1.5

Pressure / Pression Fresh air / Air frais Stale air / Air vicié

IN. W.G. Pascal CFM L/s CFM L/s

PO. d’eau (Pa) PCM PCM

0.60 149 186 88 187 88

0.58 144 182 86 184 87

0.56 139 177 84 180 85

0.54 135 172 81 176 83

0.52 130 167 79 173 82

0.50 125 162 76 169 80

0.48 120 157 74 165 78

0.46 115 152 72 161 76

0.44 110 146 69 156 74

0.42 105 141 67 152 72

0.40 100 136 64 147 69

0.38 95 130 61 143 67

0.36 90 125 59 138 65

0.34 85 119 56 133 63

0.32 80 113 53 128 60

0.30 75 107 50 123 58

0.28 70 102 48 117 55

0.26 65 96 45 112 53

0.24 60 90 42 106 50

0.22 55 84 40 100 47

0.20 50 78 37 94 44

0.18 45 71 34 88 42

0.16 40 65 31 82 39

0.14 35 59 28 76 36

0.12 30 52 25 69 33

0.10 25 46 22 62 29

0.08 20 39 18 56 26

0.06 15 33 16 49 23

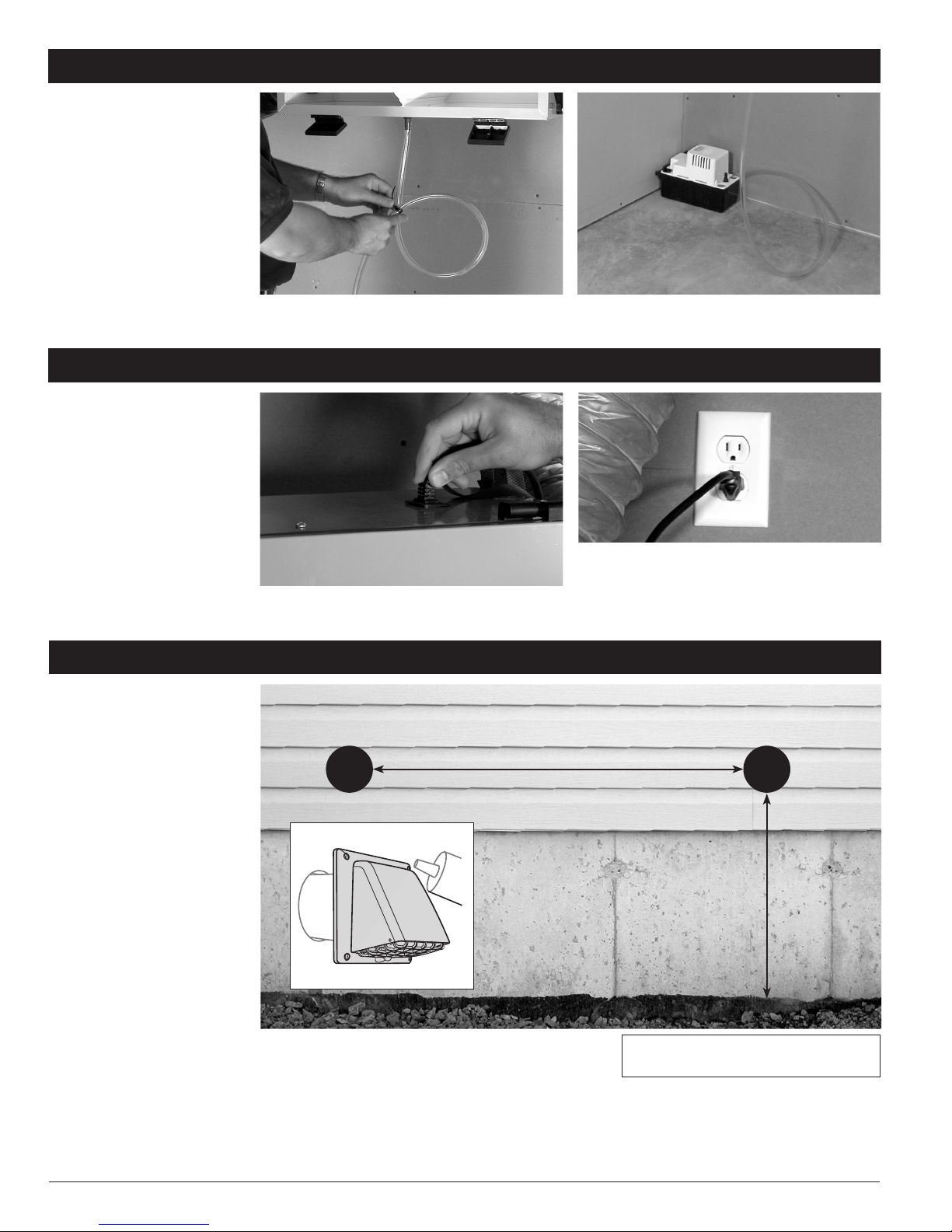

Step 5: Connect the two (2) plastic hoses from the gauge

to the HIGH & LOW balancing pressure taps on the fresh or

stale air side located on the HRV/ERV access door (Ref Fig

11.2 )

Fig 11.2

Fresh Air

from Outside

Stale Air

to Outside

Stale Air

from Home

Fresh

Air

Stale

Air

Fresh Air

to Home

Remove all four (4)

nylon knock out seals.

Do not discard.

LOWLOW

LOW

LOW

HIGH

HIGH

HIGH

HIGH

Aspiration

d'air frais

Évacuation

d'air vicié

Aspiration

d'air vicié

Air frais

Air vicié

Distribution

d'air frais

BASBAS

BAS

BAS

HAUT

HAUT

HAUT

HAUT

Enlever les quatre (4)

bouchons de nylon.

Ne pas les jeter.

Pressure / Pression Fresh air / Air frais Stale air / Air vicié

IN. W.G. Pascal CFM L/s CFM L/s

PO. d’eau (Pa) PCM PCM

0.36 90 216 102 - -

0.34 85 209 99 222 105

0.32 80 200 94 214 101

0.30 75 192 91 207 98

0.28 70 183 86 198 93

0.26 65 173 82 189 89

0.24 60 163 77 180 85

0.22 55 153 72 170 80

0.20 50 142 67 159 75

0.18 45 131 62 148 70

0.16 40 119 56 136 64

0.14 35 107 50 124 59

0.12 30 95 45 111 52

0.10 25 82 39 97 46

0.08 20 68 32 83 39

0.06 15 55 26 69 33

0.04 10 55 26 54 25

Balancing chart 2.0Balancing chart 1.5

Pressure / Pression Fresh air / Air frais Stale air / Air vicié

IN. W.G. Pascal CFM L/s CFM L/s

PO. d’eau (Pa) PCM PCM

0.60 149 186 88 187 88

0.58 144 182 86 184 87

0.56 139 177 84 180 85

0.54 135 172 81 176 83

0.52 130 167 79 173 82

0.50 125 162 76 169 80

0.48 120 157 74 165 78

0.46 115 152 72 161 76

0.44 110 146 69 156 74

0.42 105 141 67 152 72

0.40 100 136 64 147 69

0.38 95 130 61 143 67

0.36 90 125 59 138 65

0.34 85 119 56 133 63

0.32 80 113 53 128 60

0.30 75 107 50 123 58

0.28 70 102 48 117 55

0.26 65 96 45 112 53

0.24 60 90 42 106 50

0.22 55 84 40 100 47

0.20 50 78 37 94 44

0.18 45 71 34 88 42

0.16 40 65 31 82 39

0.14 35 59 28 76 36

0.12 30 52 25 69 33

0.10 25 46 22 62 29

0.08 20 39 18 56 26

0.06 15 33 16 49 23

Note: If the gauge needle drops below zero, reverse the

plastic

hose connections.

Step 6: Press the (+) and (–) buttons on the Duotrol™

simultaneously until you see the yellow light. Once the

indicator light turns yellow and the unit goes to high speed

you are in balancing mode. When in balancing mode the

selector switch on the Duotrol™ becomes the motor selector

switch. INTER (Right Motor = Stale Airflow), CONT (Both

Motors) and OFF (Left Motor = Fresh Airflow)

Step 7: To adjust the (fresh air), select the «OFF» position

on the Duotrol™. Ensure the plastic hoses from the gauge

are connected to the HIGH & LOW balancing pressure taps

on the fresh airflow side located on the HRV/ERV access

door. (Ref Fig 11.2). To adjust the airflow rates, press the

(–) button to decrease or press the (+) button to increase

the airflow rates until you reach the calculated fresh airflow

requirements.

Step 8: To adjust the (stale air)select the «INTER» position

on the Duotrol™. Ensure the plastic hoses from the gauge

are connected to the HIGH & LOW balancing pressure taps on

the stale air side located on the HRV/ERV access door. (Ref

Fig 11.2) To adjust the airflow rates, press the (–) button to

decrease or press the (+) button to increase the airflow rates

until you reach the calculated stale airflow requirements.

Step 9: Once this is completed, you have balanced the

airflow rates of your HRV/ERV. To exit the balancing mode

you must press (+) and (–) buttons on the Duotrol™

simultaneously until solid green LED appears then release.

The indicator light will turn green to indicate normal operation

mode. Seal the (4) four balancing pressure taps with the

nylon knock out seals removed in Step 4.

Step 10: Mark down the balanced air flow rates information

on a label including in the kit. Apply the label to the HRV/ERV

access door for future reference (e.g. date, balance airflow

rate, your name, phone number and business address).

Note: Once the HRV/ERV is balanced, switch to «CONT» on

the Duotrol™ By using (+) and (–) buttons you can set the

continuous speed.

For Balancing Charts,

- Refer to page 16 of this manual

- Visit www.greentek.ca

- Scan QR code with your smartphone

RNC 1.5 Balancing Chart

RNC 2.0 Balancing Chart

RNC 2.0ES Balancing Chart