MicroGuard 511 Retrofit i W450512 03/08

Contents

Introduction......................................................................................................................................................................................... 1

System Components............................................................................................................................................................... 1

Extension Sensor ...................................................................................................................................................................... 1

Pressure Transducers........................................................................................................................................................... 1

Anti Two Block (ATB)............................................................................................................................................................... 1

Display............................................................................................................................................................................................ 1

Function Kick-Out ...................................................................................................................................................................... 2

Operator Settable Alarms .................................................................................................................................................... 2

Boom Angle Sensor................................................................................................................................................................. 2

Area Alarm .................................................................................................................................................................................. 2

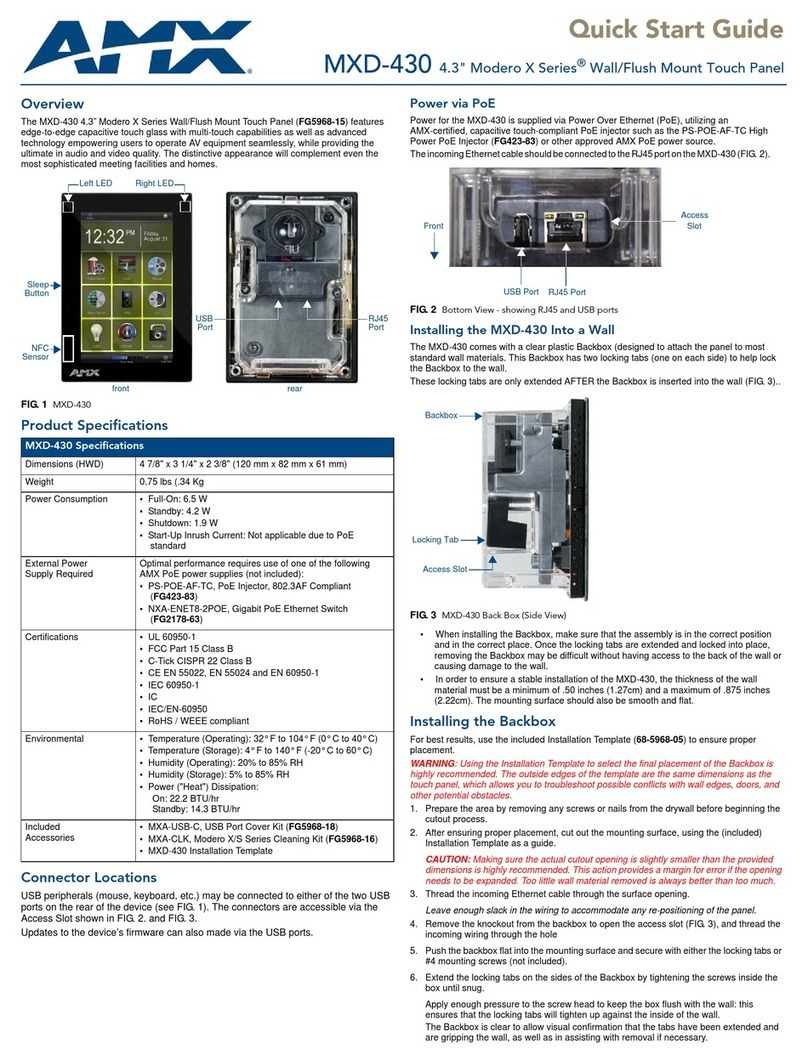

Operator Console ............................................................................................................................................................................. 3

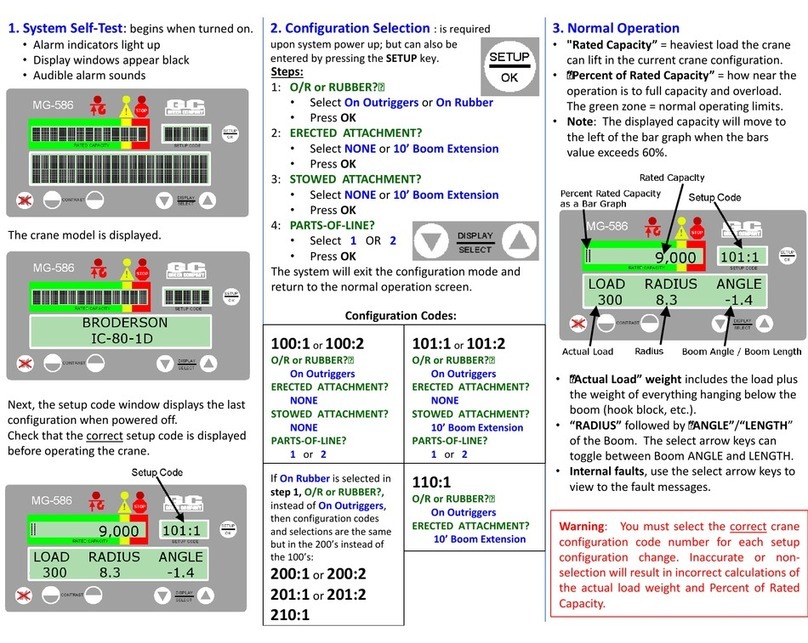

Crane Configuration ............................................................................................................................................................... 3

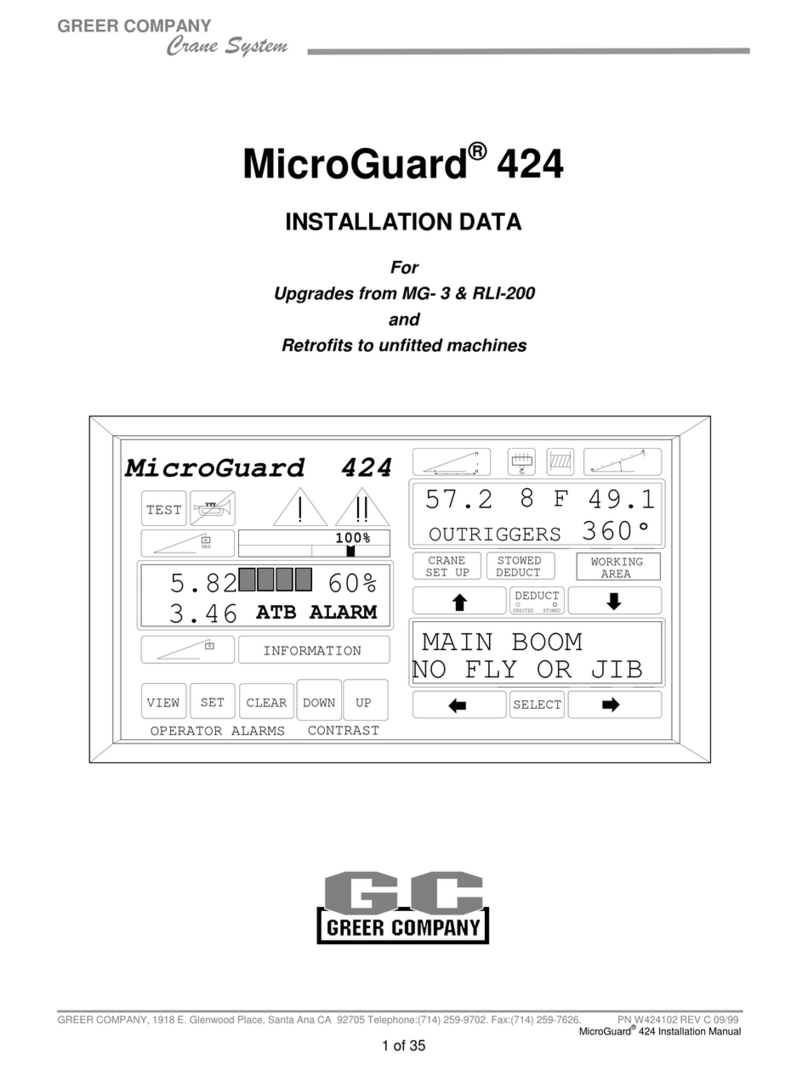

Display Console.......................................................................................................................................................................... 4

Operation.............................................................................................................................................................................................. 6

Power Up Self-Test................................................................................................................................................................... 6

Adjusting Brightness & Contrast ..................................................................................................................................... 6

Counterweight............................................................................................................................................................................ 7

Outriggers .................................................................................................................................................................................... 7

Tires and Rigging/Travel...................................................................................................................................................... 7

Stowing the Jib........................................................................................................................................................................... 8

Erecting the Jib ........................................................................................................................................................................ 8

Auxiliary Head............................................................................................................................................................................. 8

Selecting the Winch ................................................................................................................................................................ 8

Setting the Parts of Line ...................................................................................................................................................... 9

Cancel Alarm Button............................................................................................................................................................... 9

Reset Function Kick-Out .................................................................................................................................................... 10

Operator Settable Alarms ................................................................................................................................................ 10

Accessing the Operator Alarms............................................................................................................................. 10

Setting Minimum Boom Angle Alarm................................................................................................................... 10

Setting Maximum Boom Angle Alarm ................................................................................................................ 11

Setting Maximum Boom Length Alarm .............................................................................................................. 11

Setting Maximum Tip Height Alarm...................................................................................................................... 11

Accessing Swing and Work Area Alarms.......................................................................................................... 11

Swing Alarms ......................................................................................................................................................................... 12

Setting the Swing Left and Swing Right Alarms.............................................................................................. 12

Setting the Work Area Alarm.................................................................................................................................. 15