Link-Belt MG-534 Calibration i W450160 10/07

Table of Contents

Introduction......................................................................................................................................................................................... 1

Required Tools ........................................................................................................................................................................... 1

Number Conversion ................................................................................................................................................................ 1

Number Entry ............................................................................................................................................................................. 2

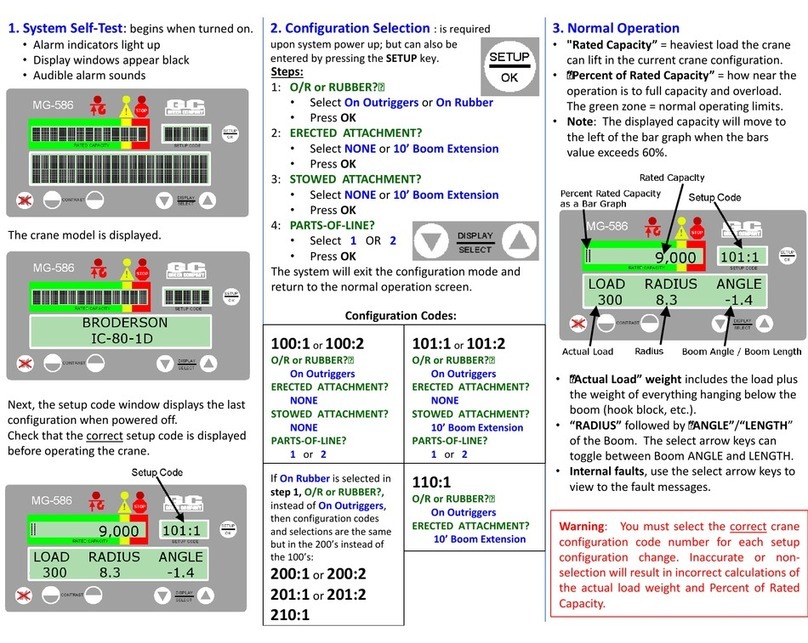

The Display................................................................................................................................................................................... 3

Calibration Mode .............................................................................................................................................................................. 4

Menu 00 – Error Codes ............................................................................................................................................................... 6

Group “A” Fault Codes............................................................................................................................................................ 7

Group “B” Fault Codes............................................................................................................................................................ 9

Group “C” Fault Codes......................................................................................................................................................... 10

Group “D” Fault Codes......................................................................................................................................................... 11

Menu 01 – Crane Data.............................................................................................................................................................. 12

Menu 02 – Zero Sensor............................................................................................................................................................ 14

Boom Extension Sensor Zero.......................................................................................................................................... 14

Boom Angle Sensor Zero .................................................................................................................................................. 15

Menu 03 – Span ........................................................................................................................................................................... 17

Boom Angle Sensor.............................................................................................................................................................. 17

Boom Extension Sensor ..................................................................................................................................................... 18

Menu 04 – Swing Pot Zero...................................................................................................................................................... 20

Swing Pot Zero ....................................................................................................................................................................... 20

Swing Pot Direction .............................................................................................................................................................. 21

Menu 05 – Main Boom Radius/Moment......................................................................................................................... 22

First Length .............................................................................................................................................................................. 23

Second Length ........................................................................................................................................................................ 25

Third Length............................................................................................................................................................................. 27

Menu 06 – Boom Deflection Correction ........................................................................................................................... 30

Menu 07 – Head Angle.............................................................................................................................................................. 32

Menu 08 – Attachments .......................................................................................................................................................... 35

Menu 09 – Winches ................................................................................................................................................................... 37

Menu 10 – Rope Limits............................................................................................................................................................. 39

Menu 11 – Alarms....................................................................................................................................................................... 41

Menu 12 – Digital Inputs........................................................................................................................................................... 43

Menu 13 – Monitor ..................................................................................................................................................................... 44

Menu 15 – Pressure .................................................................................................................................................................. 45

Appendix A....................................................................................................................................................................................... A-1

Glossary of terms ................................................................................................................................................................. A-1