-2- G9933 Update (Mfd. Since 05/22)

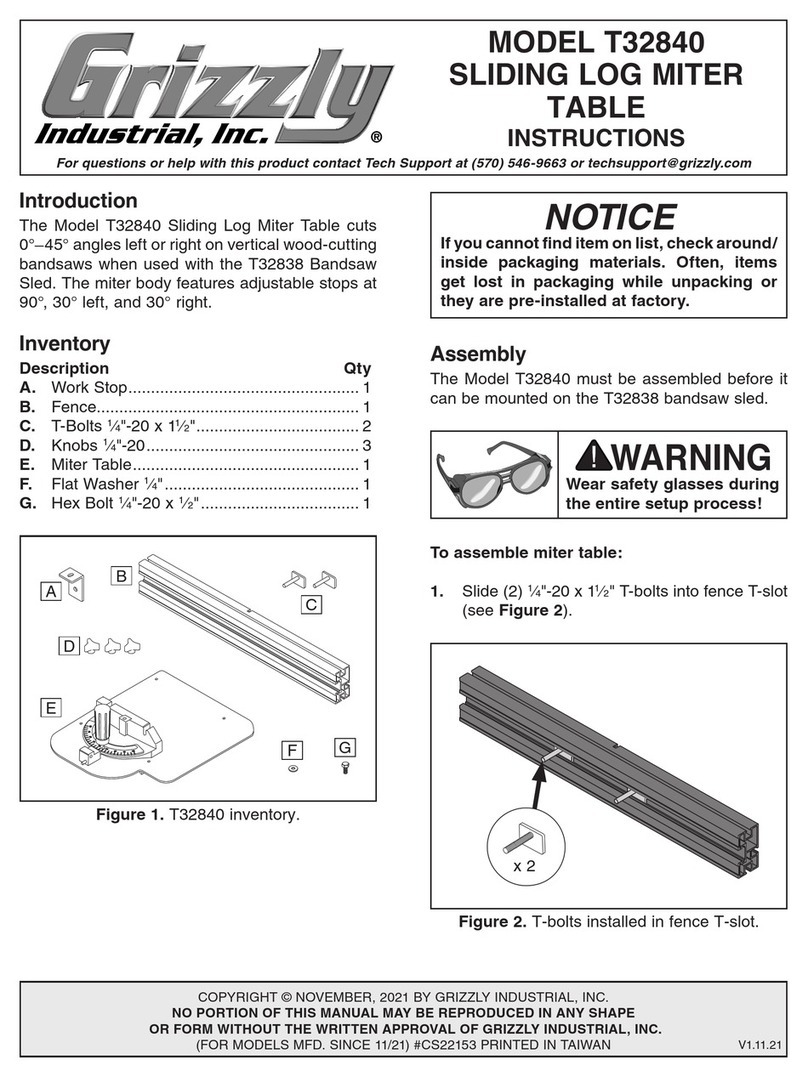

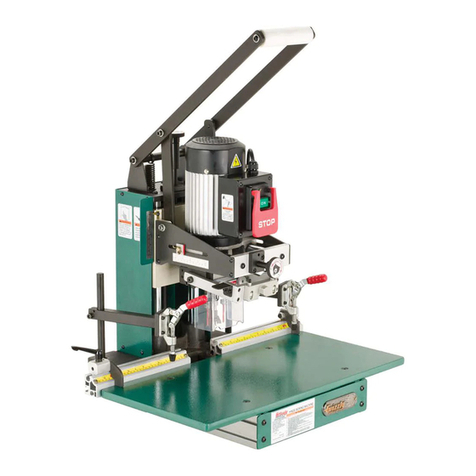

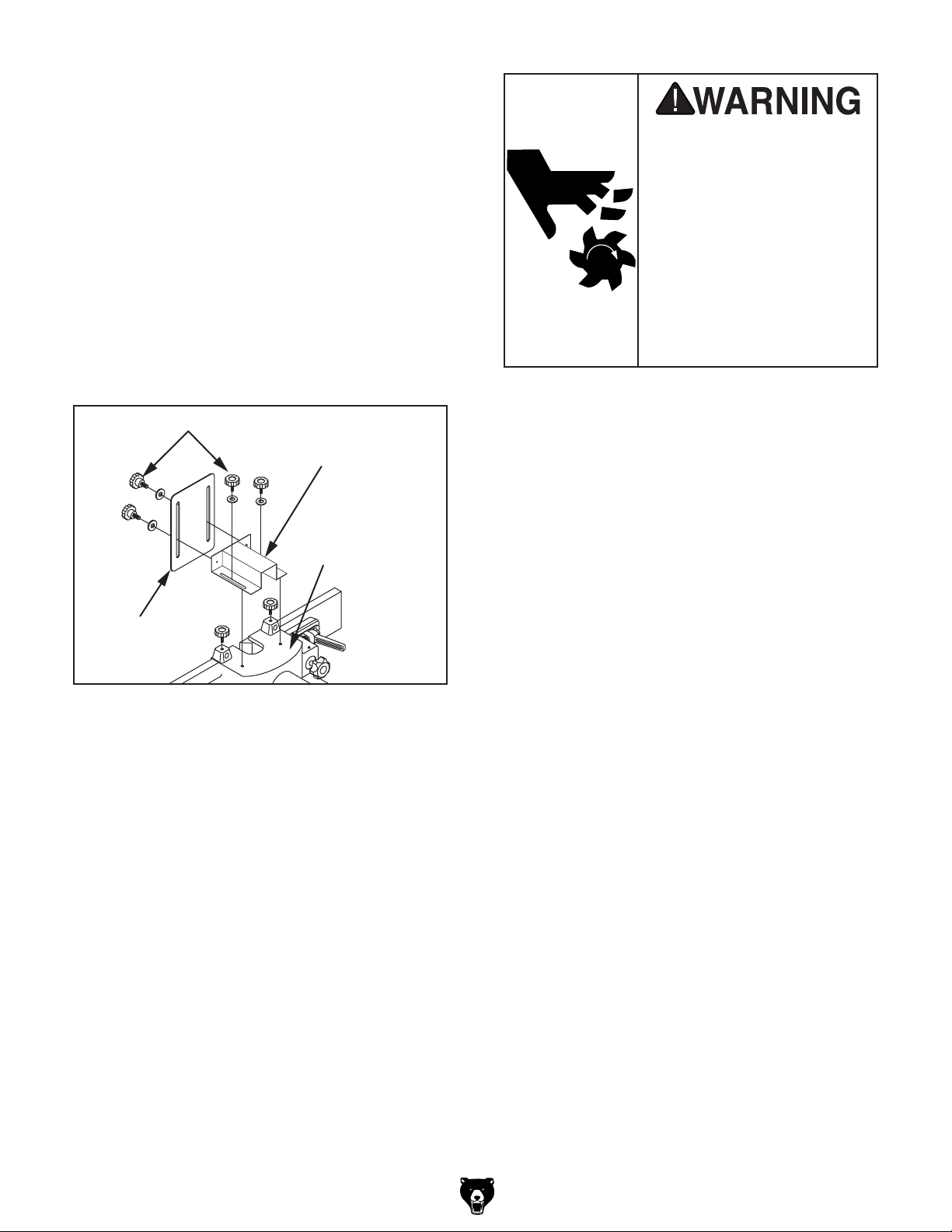

3. Secure the fence and guard assemblies to

the table with (6) M10-1.5 x 30 hex bolts and

10mm flat washers, as shown in Figure 1.

Connect an adequate dust collection system to

the 4" central dust hood. Make sure the dust

hose is supported in a vertical position above the

shaper table so that it is not in contact with any

other part of the shaper and will not interfere with

safe working conditions at each station.

Figure 1. Securing fence assembly and guard to

the table.

Guard Dust Port

x 6

Mounting Slot

Test Run

(Replaces Page 17 in Owner's Manual)

Dust Collection

Minimum CFM at Each Dust Port: 400 CFM

Do not confuse CFM recommendation with rat-

ing of dust collector. To determine CFM at dust

port, you must consider these variables: (1)

CFM rating of dust collector, (2) hose type and

length between dust collector and machine, (3)

number of branches or wyes, and (4) amount of

other open lines throughout system. Explaining

how to calculate these variables is beyond

scope of this manual. Consult expert or pur-

chase good dust collection "how-to" book.

This machine creates a lot of wood chips/

dust during operation. Breathing airborne

dust on a regular basis can result in perma-

nent respiratory illness. Reduce your risk

by wearing a respirator and capturing the

dust with a dust-collection system.

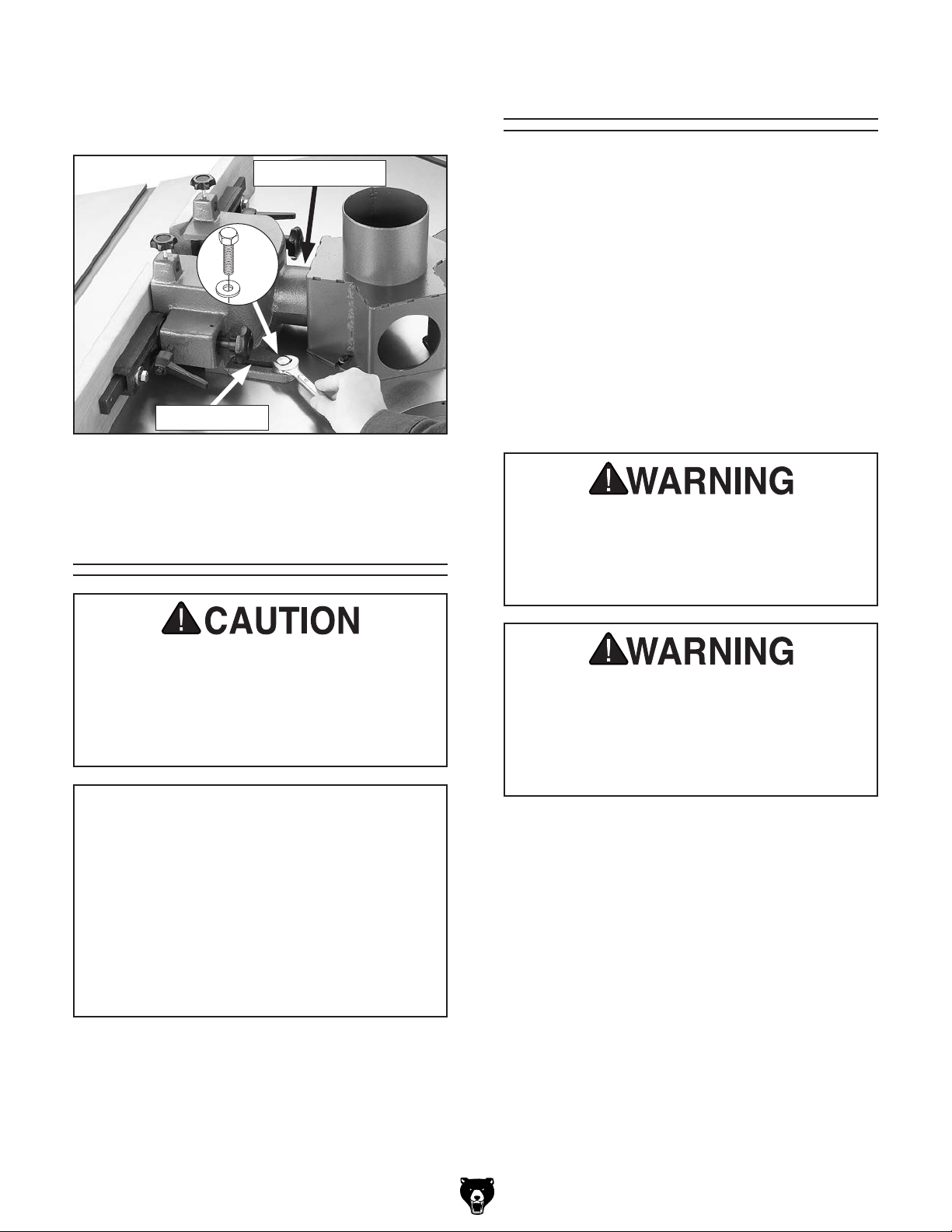

DO NOT start machine until all preceding

setup instructions have been performed.

Operating an improperly set up machine

may result in malfunction or unexpect-

ed results that can lead to serious injury,

death, or machine/property damage.

Serious injury or death can result from

using this machine BEFORE understanding

its controls and related safety information.

DO NOT operate, or allow others to operate,

machine until the information is understood.

To test run machine:

1. Clear all setup tools away from machine.

2. Press all EMERGENCY STOP buttons in.

3. Turn all spindle switches to OFF position.

4. Connect machine to power.

5. Twist EMERGENCY STOP buttons clockwise

until they spring out. This resets switches so

machine can start.

Once assembly is complete, test run the machine

to ensure it is properly connected to power and

safety components are functioning correctly.

If you find an unusual problem during the test run,

immediately stop the machine, disconnect it from

power, and fix the problem BEFORE operating the

machine again. The

Troubleshooting

table in the

SERVICE section of this manual can help.

The Test Run consists of verifying the following:

1) The motors power up and run correctly, and 2)

the EMERGENCY STOP button safety features

are functioning properly.