Table of Contents

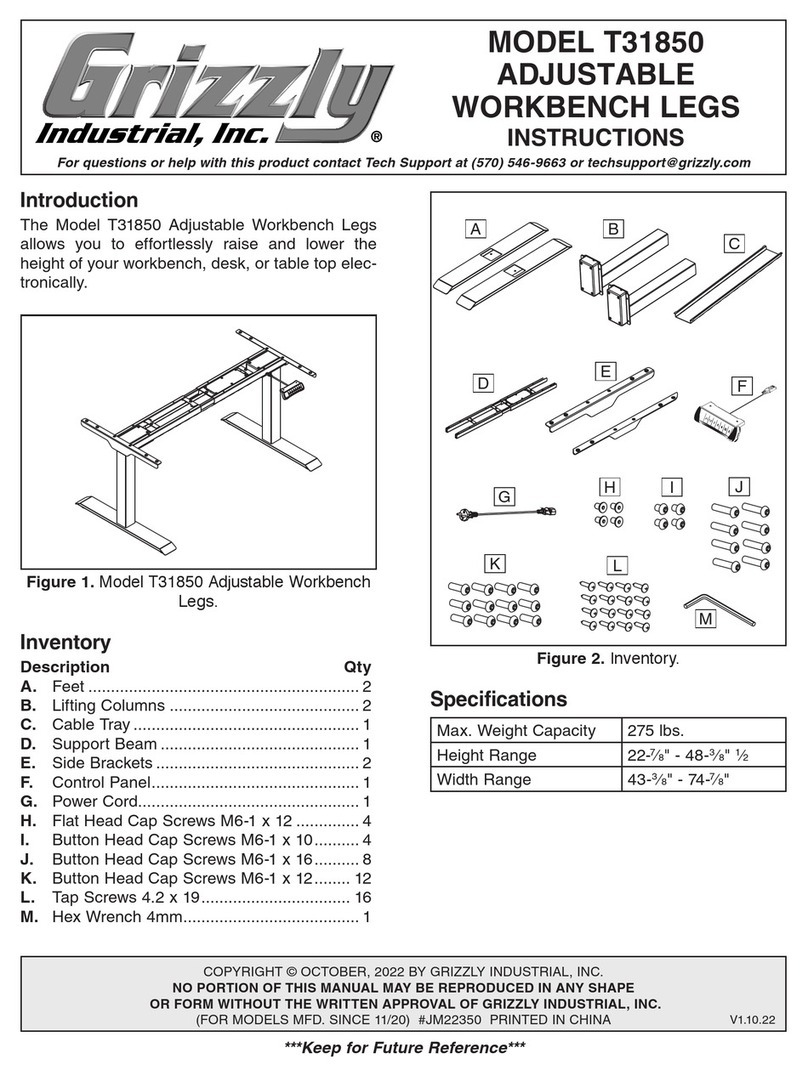

INTRODUCTION............................................... 2

Manual Accuracy ........................................... 2

Contact Info.................................................... 2

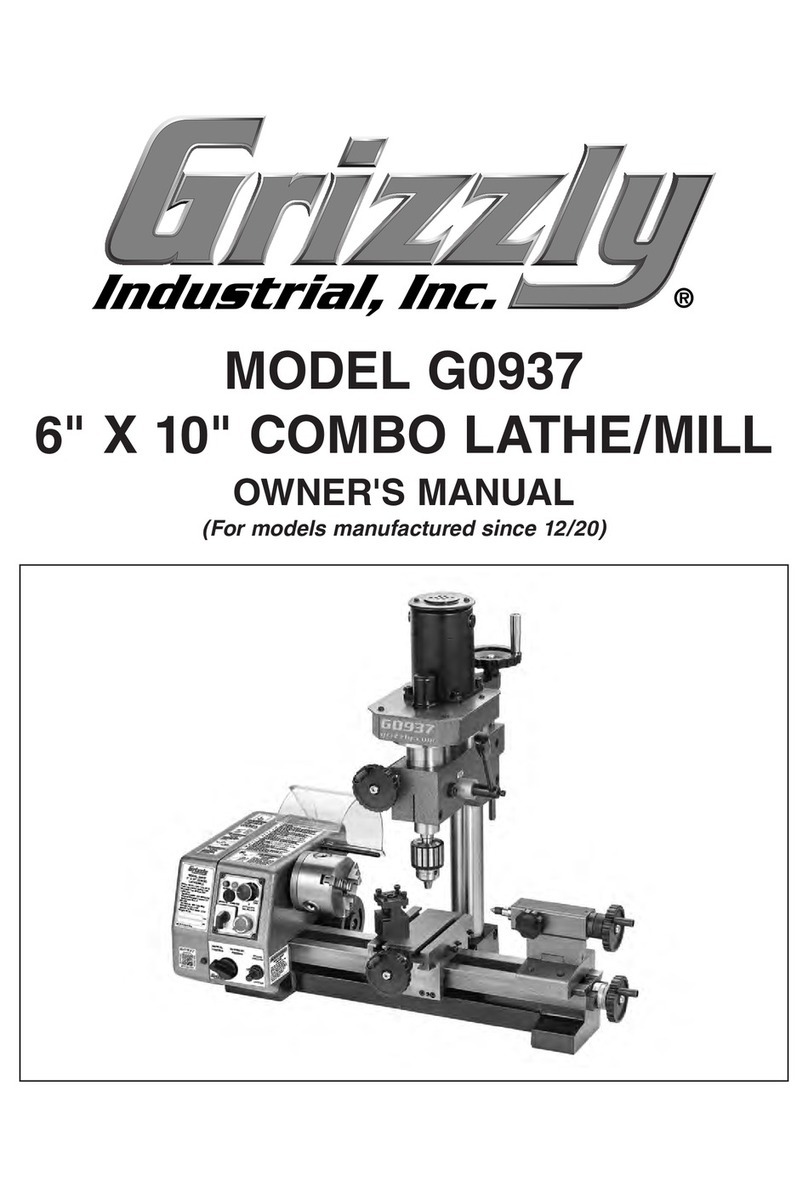

Machine Description ...................................... 2

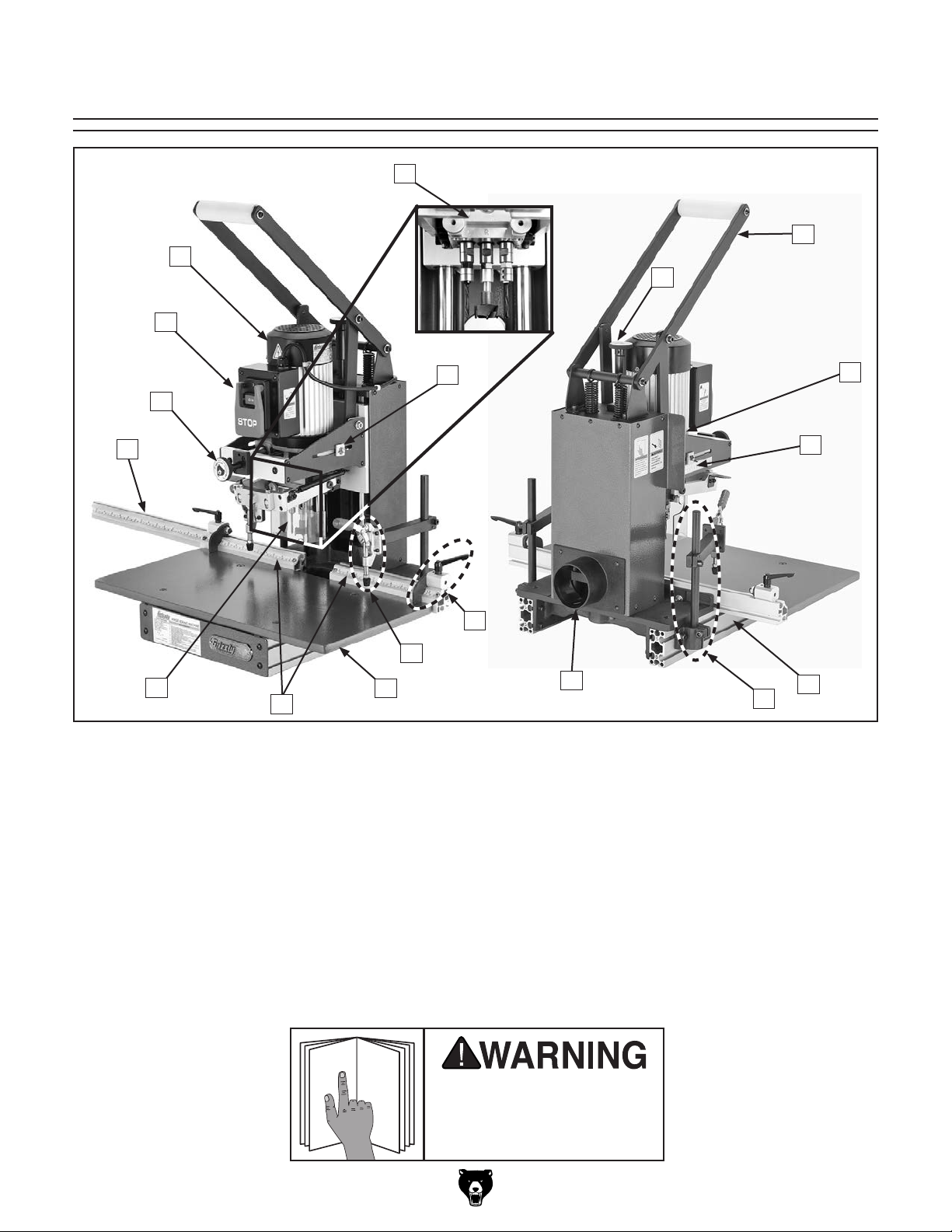

Identification ................................................... 3

Machine Data Sheet ...................................... 4

SECTION 1: SAFETY....................................... 6

Safety Instructions for Machinery .................. 6

Additional Safety for Boring Machines ........... 8

SECTION 2: POWER SUPPLY ........................ 9

Availability .................................................... 9

Full-Load Current Rating ............................. 9

Circuit Information ....................................... 9

Circuit Requirements for 110V .................... 9

Circuit Requirements for 220V .................... 9

Grounding Requirements .......................... 10

Extension Cords ........................................ 10

Voltage Conversion ................................... 11

SECTION 3: SETUP ....................................... 12

Needed for Setup ......................................... 12

Unpacking .................................................... 12

Inventory ...................................................... 13

Cleanup ........................................................ 13

Site Considerations ...................................... 14

Weight Load .............................................. 14

Space Allocation ........................................ 14

Physical Environment ................................ 14

Electrical Installation .................................. 14

Lighting ...................................................... 14

Lifting & Placing ........................................... 15

Mounting ...................................................... 15

Assembly ..................................................... 16

Dust Collection ............................................. 19

Power Connection........................................ 19

Connecting Power ..................................... 19

Disconnecting Power ................................. 19

Test Run ...................................................... 20

SECTION 4: OPERATIONS ........................... 21

Basic Controls .............................................. 21

Disabling & Locking Switch.......................... 22

Setup Overview............................................ 22

Operation Overview ..................................... 22

Hold-Down Clamps ...................................... 23

Boring Head Setup ...................................... 24

Selecting Boring Head & Bits .................... 24

Replacing Boring Head ............................. 24

Installing & Adjusting Boring Bits .............. 25

Headstock Setup.......................................... 26

Drilling Depth ............................................. 27

Setback Distance ....................................... 27

Operation ................................................... 28

Swing Arm Test Fit & Adjustment ............. 28

Fence Stop Setup ........................................ 29

Determining Number of Hinges ................. 29

Two-Hinge Door ........................................ 30

Three-Hinge Door ...................................... 30

Four-Hinge Door ........................................ 31

SECTION 5: ACCESSORIES ......................... 32

SECTION 6: MAINTENANCE......................... 35

Schedule ...................................................... 35

Cleaning ....................................................... 35

Lubrication ................................................... 35

Headstock Slides ....................................... 36

Depth & Throat Adjustment Shafts ............ 36

Pivot Points ................................................ 36

Boring Head Assembly .............................. 36

SECTION 7: SERVICE ................................... 37

Troubleshooting ........................................... 37

Motor & Electrical ...................................... 37

Operation ................................................... 38

SECTION 8: WIRING...................................... 39

Wiring Safety Instructions ............................ 39

Wiring Diagram ............................................ 40

110V Wiring ............................................... 40

Machine Re-wired for 220V ....................... 40

SECTION 9: PARTS....................................... 41

Body ............................................................. 41

Table ............................................................ 43

Headstock .................................................... 44

Handle .......................................................... 45

Machine Labels ............................................ 46

WARRANTY AND RETURNS ........................ 49