16.

Step 19

Step 17

17.

Note:Use the shims from your old cutterhead

if available. If not available, newspaper is

approximately 0.003" thick and will work for

shimming (we don't recommend shimming

more than 0.004" on either side, as this may

affect how the bearing block seats in the cast-

ing).

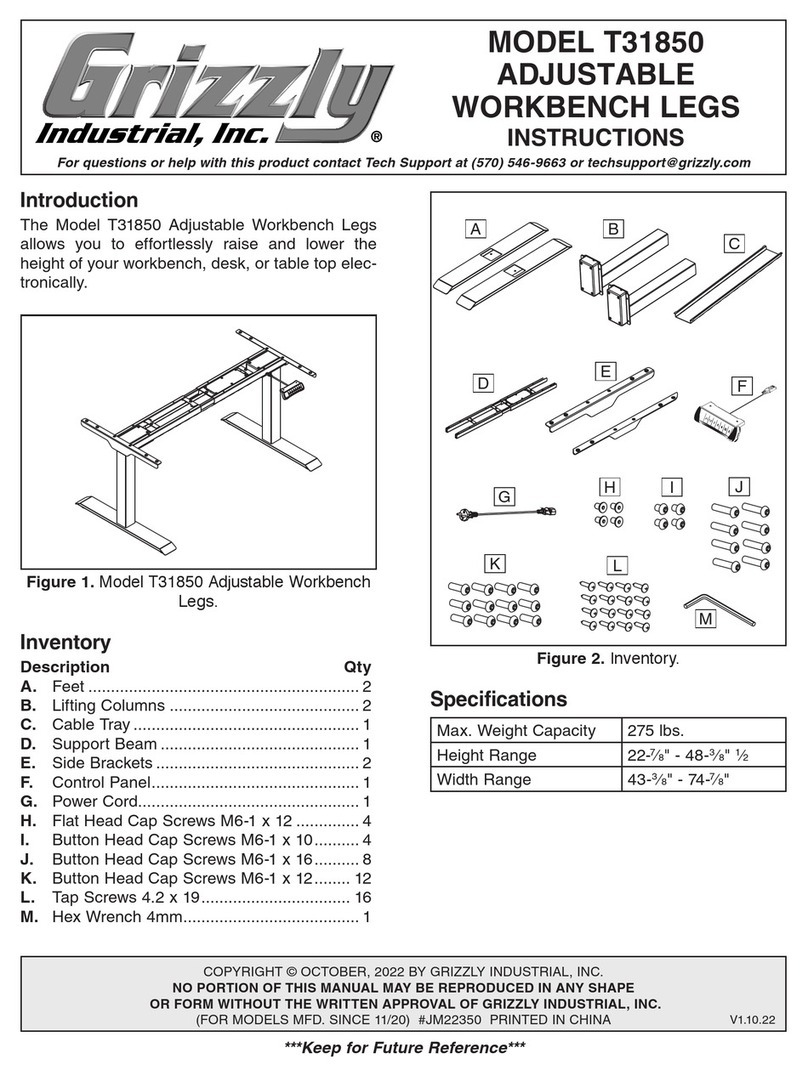

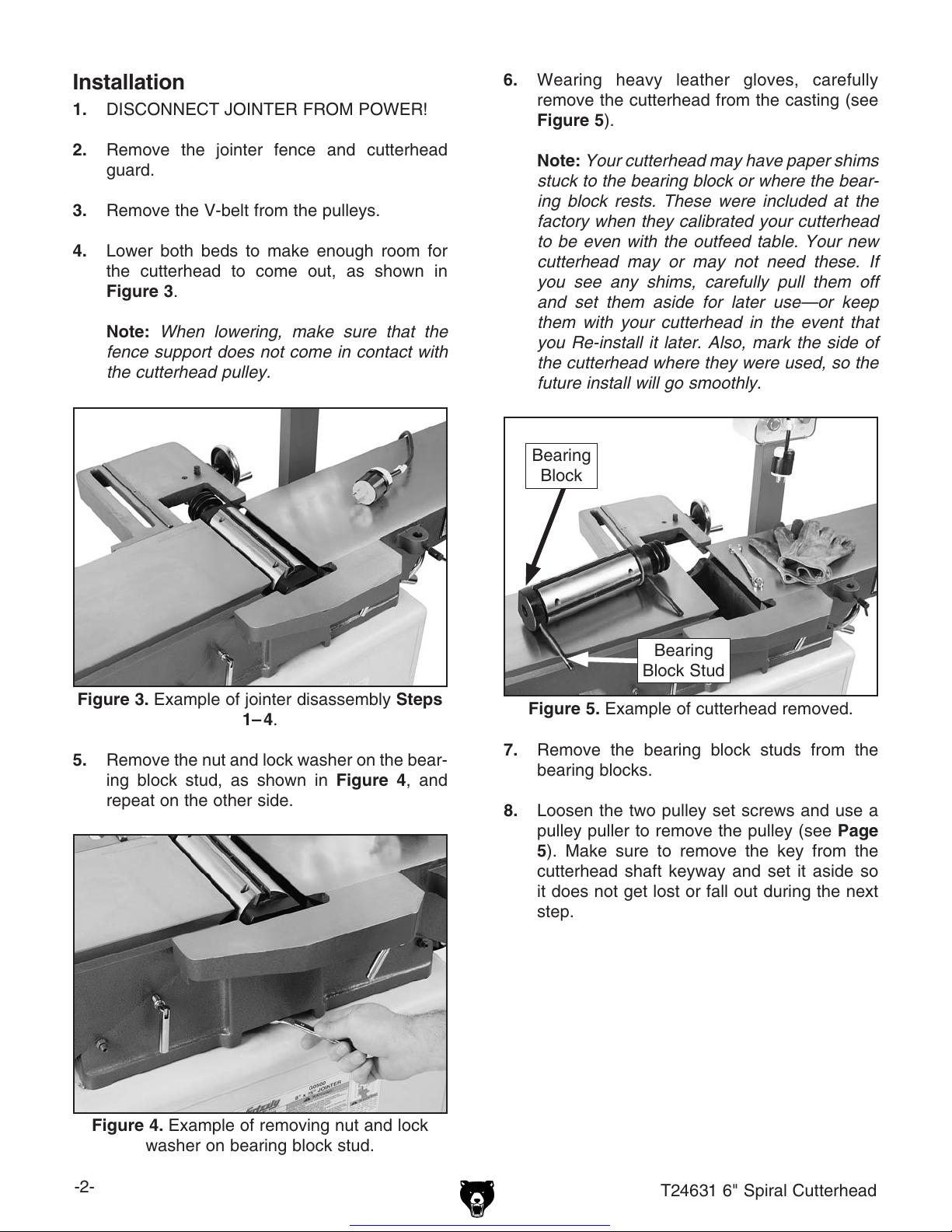

18. Steps 15–17

Straightedge

Outfeed Table

Figure 7.

14.

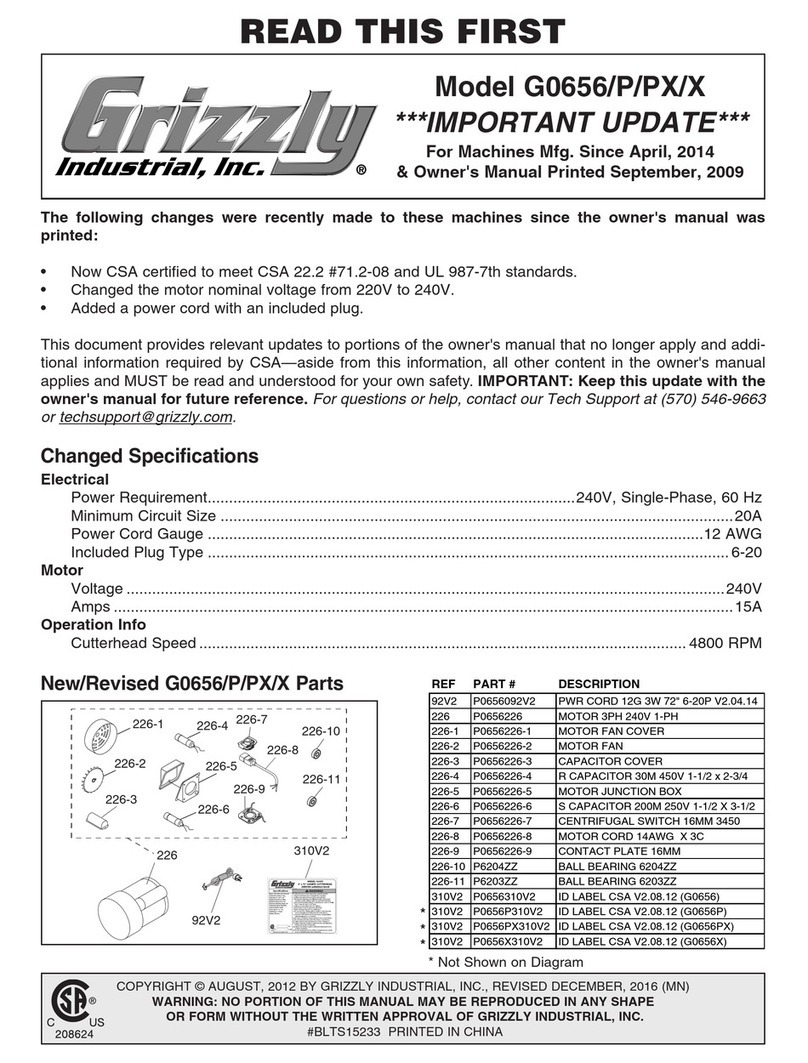

Figure 6.

15.

Figure 7

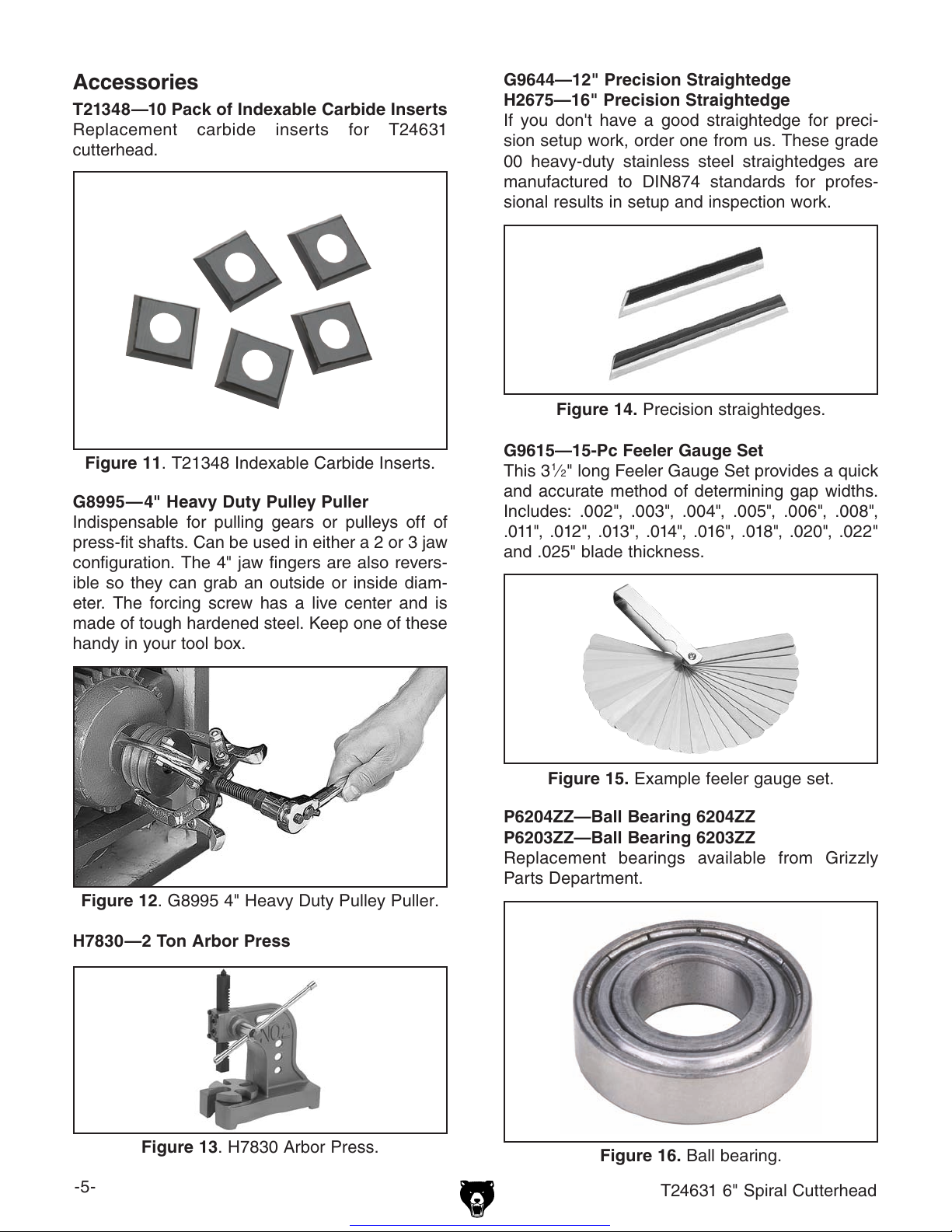

9.

Note: It is difficult to remove the bearings

without damaging them. This is why we

strongly recommend installing new bearings

on the cutterhead—instead of trying to reuse

the original ones and then repeating this pro-

cedure again in the near future.

10.

11.

12.

13. Figure 6

Get other manuals https://www.bkmanuals.com