G4003G Gunsmith's Lathe -1-

Table of Contents

INTRODUCTION ............................................... 2

Foreword ........................................................ 2

Contact Info ................................................... 2

Machine Data Sheet ...................................... 3

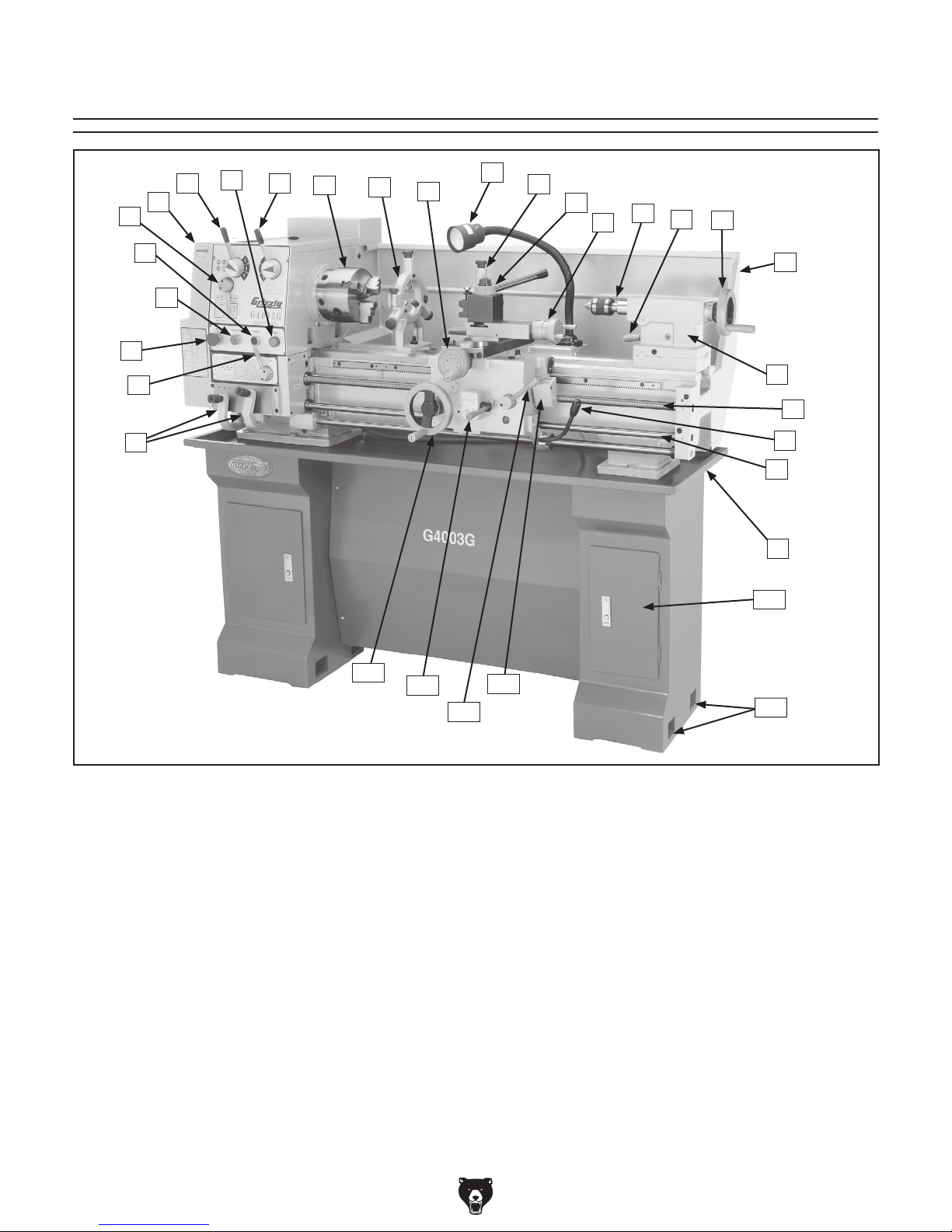

Identification ................................................... 5

SECTION 1: SAFETY ....................................... 6

Additional Safety Instructions for Lathes ....... 8

Glossary of Terms ......................................... 9

SECTION 2: CIRCUIT REQUIREMENTS ...... 10

220V Single-Phase ...................................... 10

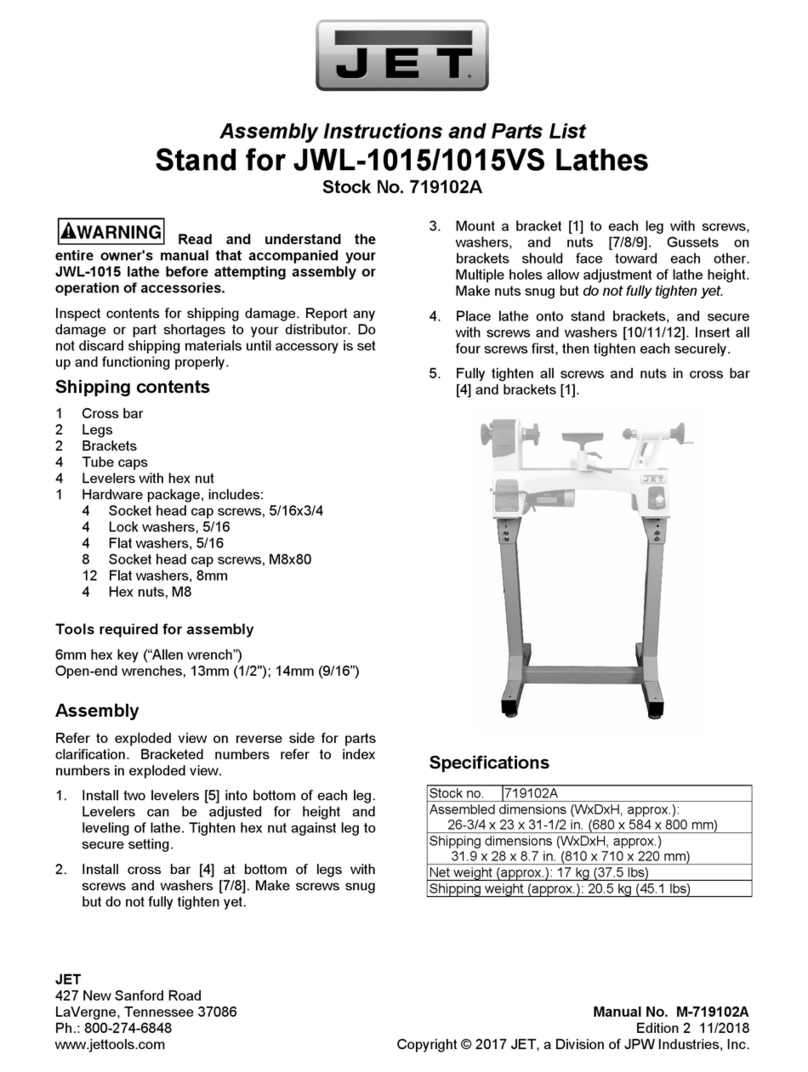

SECTION 3: SETUP ....................................... 11

Setup Safety ................................................ 11

Items Needed for Setup ............................... 11

Unpacking .................................................... 11

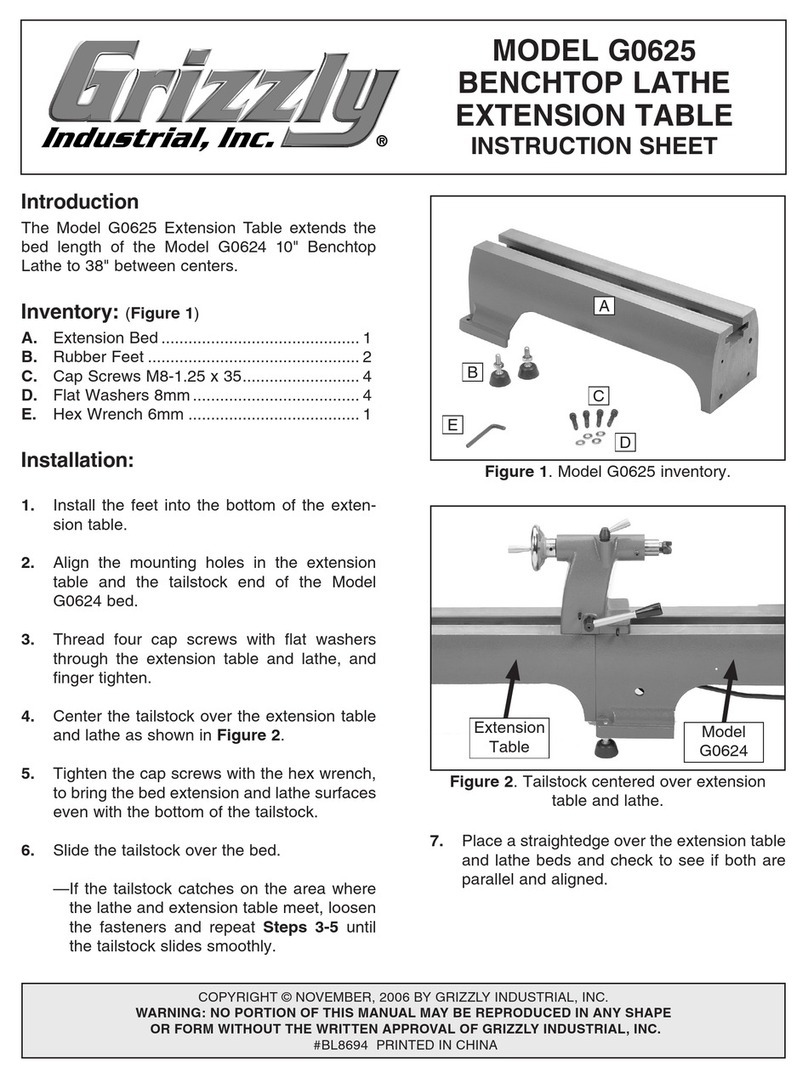

Inventory ...................................................... 12

Site Considerations ...................................... 13

Clean Up ...................................................... 13

Mounting to Shop Floor ............................... 14

Cabinet Base Assembly ............................... 14

Lifting & Moving ........................................... 15

Test Run & Break-In ................................... 16

Tailstock Setup ............................................ 17

SECTION 4: OPERATION .............................. 19

Operation Safety .......................................... 19

Spindle Speeds ............................................ 19

Mounting Chuck and Faceplate .................. 20

Centers ........................................................ 22

Spider ........................................................... 22

Steady Rest ................................................. 23

Follow Rest .................................................. 23

Feed Direction Lever ................................... 24

Feed Rod Lever ........................................... 24

Gearbox Levers ........................................... 25

Feed Rate Chart .......................................... 25

Carriage/Cross Feed Lever ......................... 26

Half-Nut Lever and Inch Threading ............. 26

Change Gears and Metric Threading .......... 28

Carriage Handwheels .................................. 29

Tool Post & Holder ...................................... 30

Tailstock Controls ........................................ 30

SECTION 5: ACCESSORIES ......................... 31

SECTION 6: MAINTENANCE ......................... 33

Basic Maintenance ...................................... 33

Lubrication ................................................... 33

SECTION 7: SERVICE ................................... 35

Troubleshooting ........................................... 35

Gibs .............................................................. 37

Bearing Preload ........................................... 38

Wiring—Electrical Box ................................ 41

Wiring—Motor & Control Panel .................. 43

Wiring—Plug, Light & Spindle Switch ......... 45

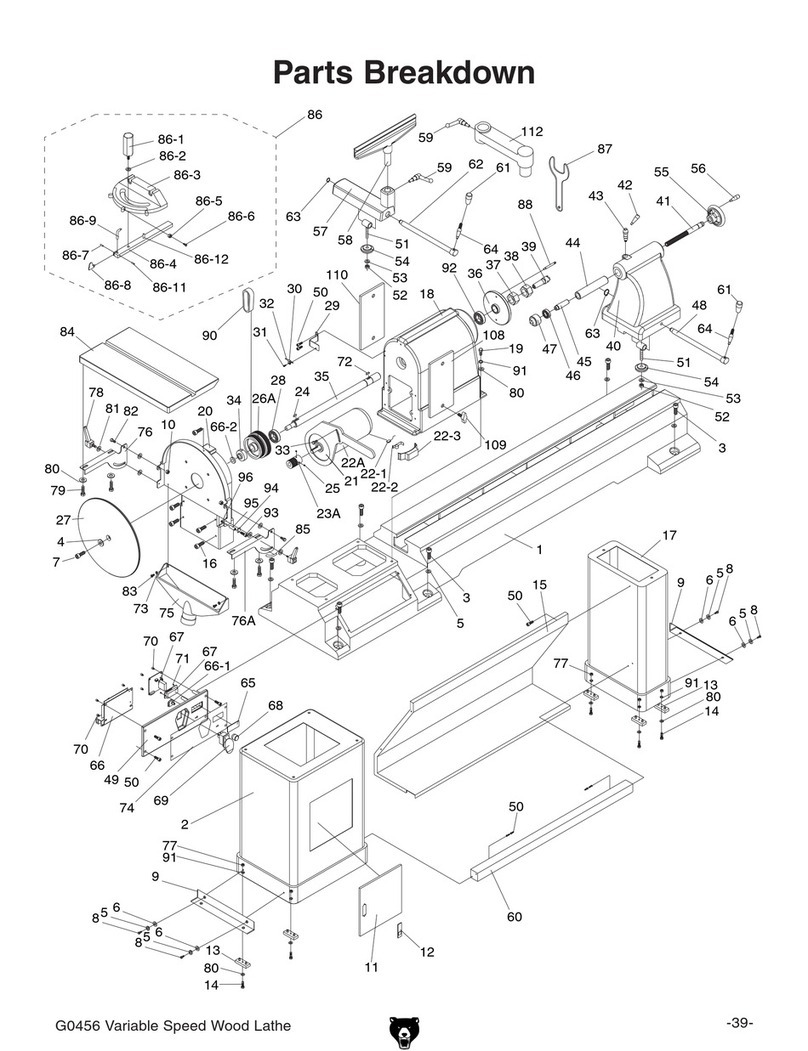

SECTION 8: PARTS ....................................... 47

Components ................................................. 47

Gearbox Gearing ......................................... 48

Gearbox Shifters .......................................... 50

Quick Change System ................................. 52

Apron ........................................................... 54

Saddle .......................................................... 56

Compound Slide .......................................... 58

Tailstock ....................................................... 59

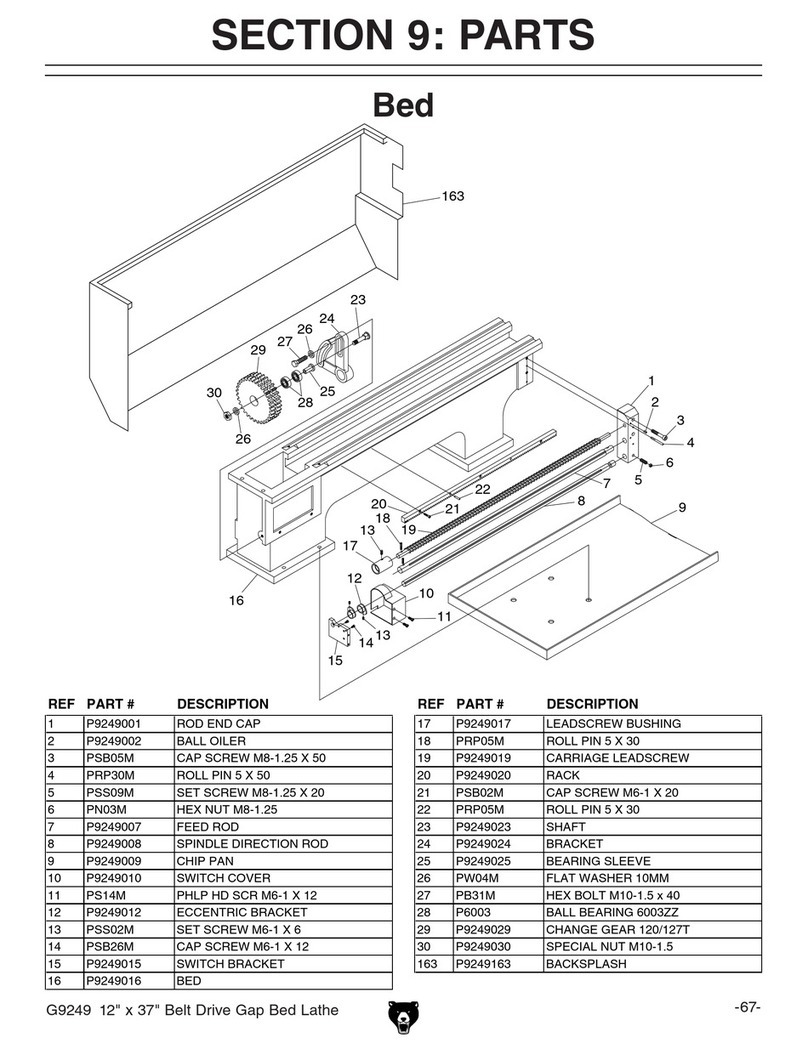

Lathe Bed & Motor ....................................... 60

Base ............................................................. 61

Feed Rod ..................................................... 63

Machine Labels ............................................ 64

Electrical Components ................................. 65

Steady & Follow Rest Assemblies ............... 66

WARRANTY AND RETURNS ........................ 69