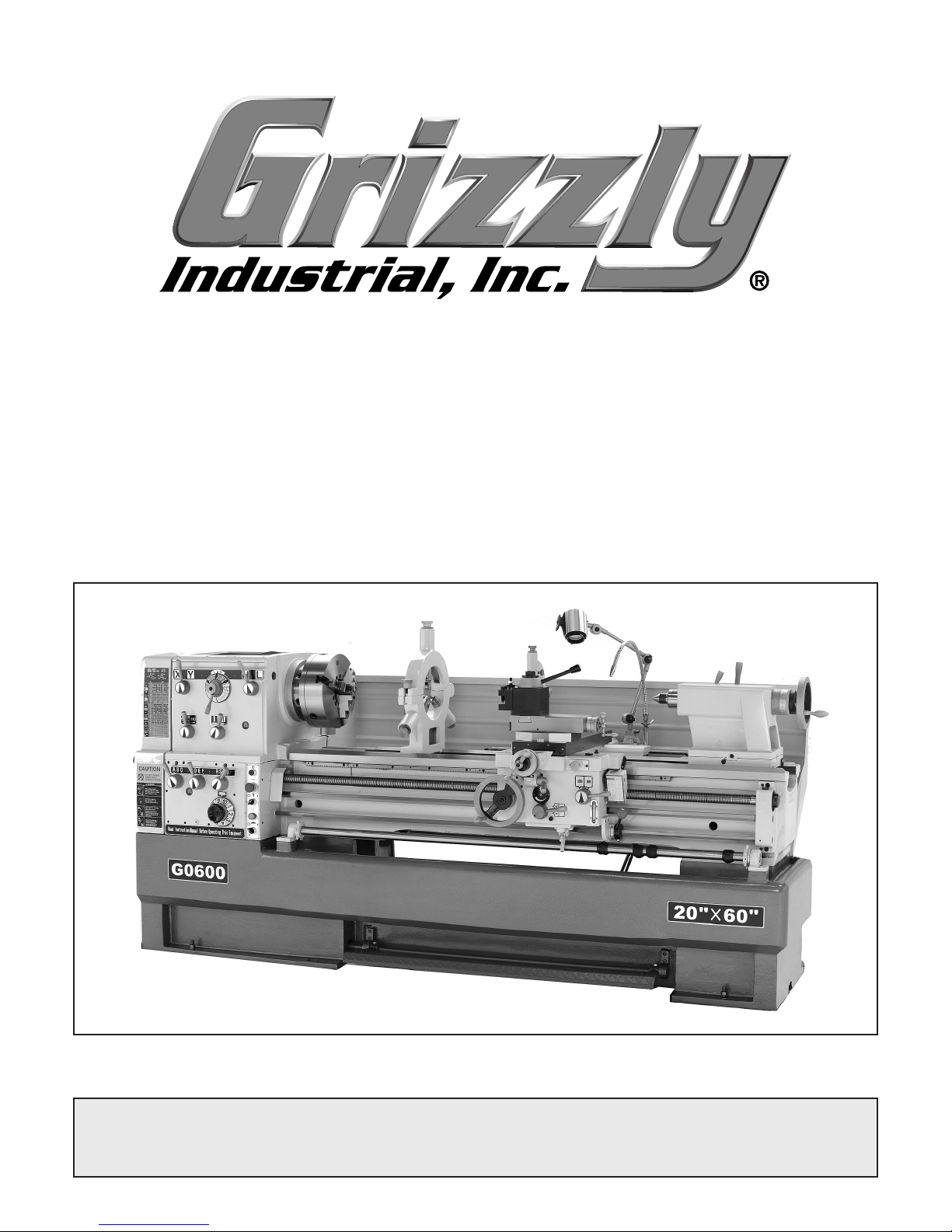

Table of Contents

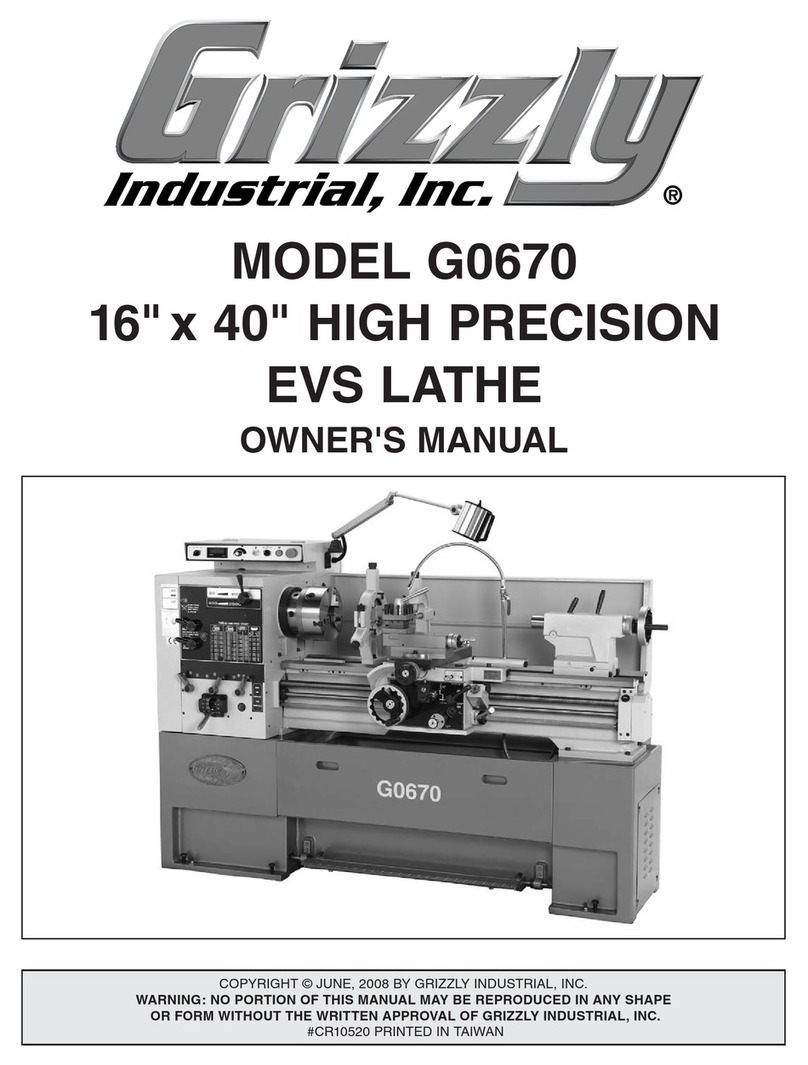

INTRODUCTION ............................................................................................................................... 3

Foreword .................................................................................................................................... 3

Contact Info ................................................................................................................................ 3

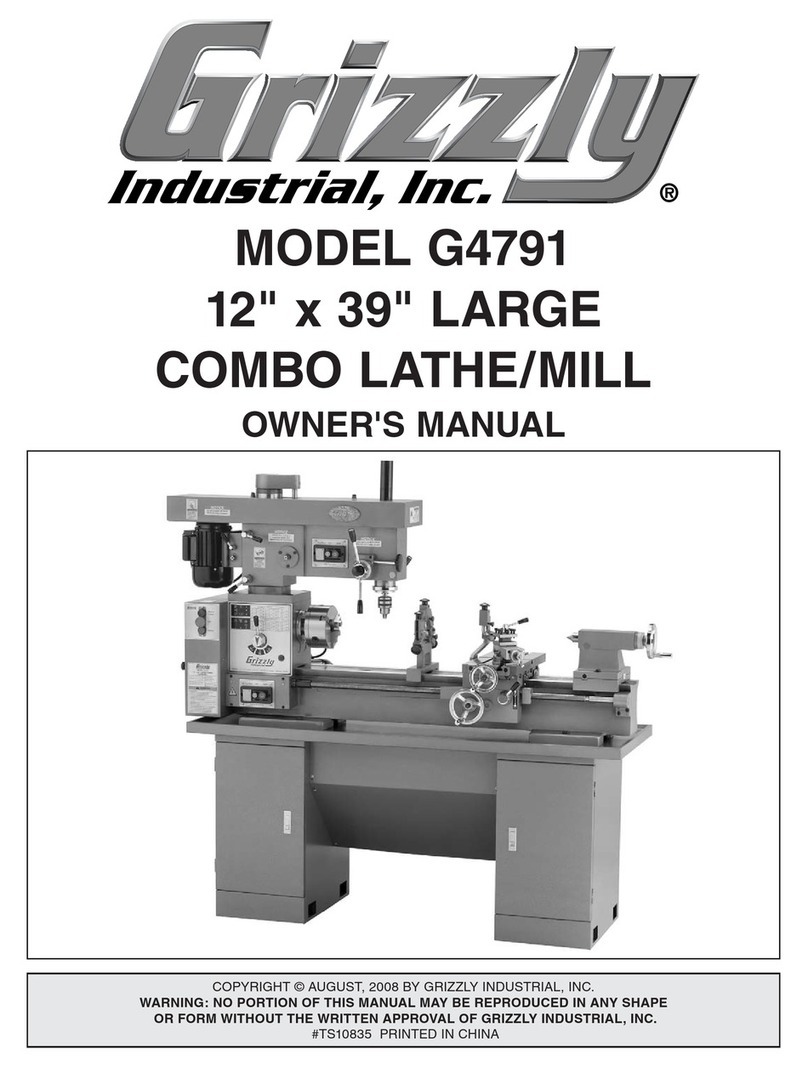

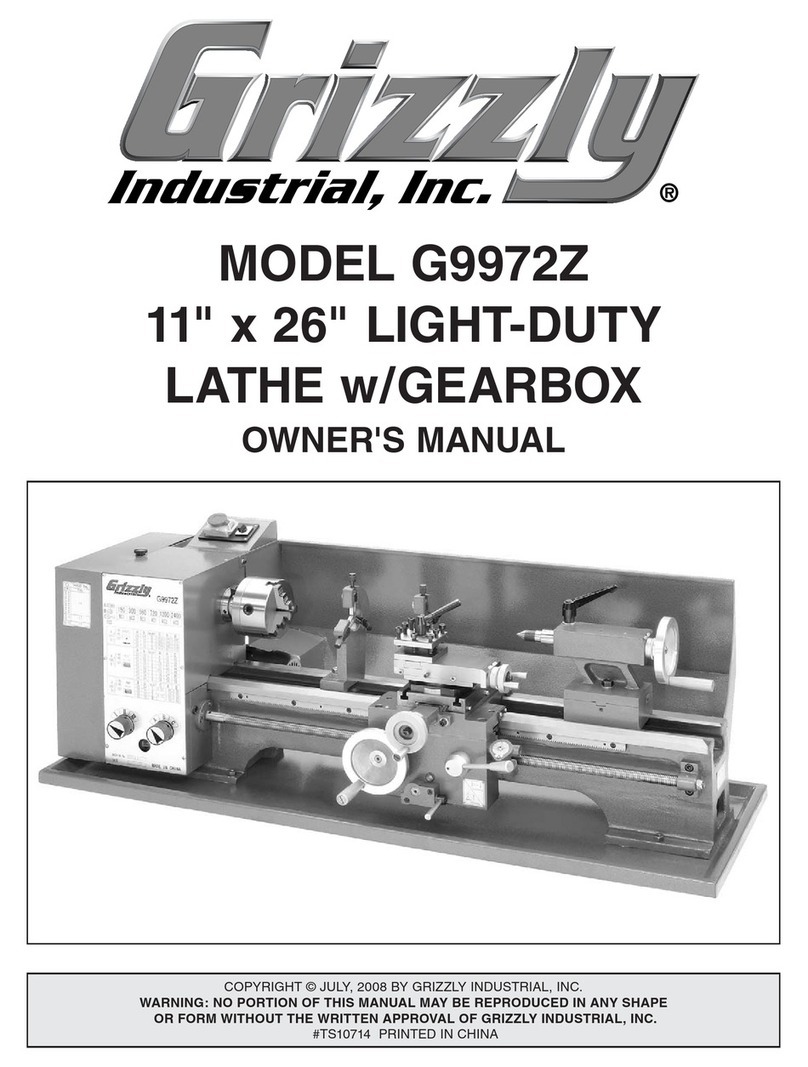

G0600 Data Sheet ..................................................................................................................... 4

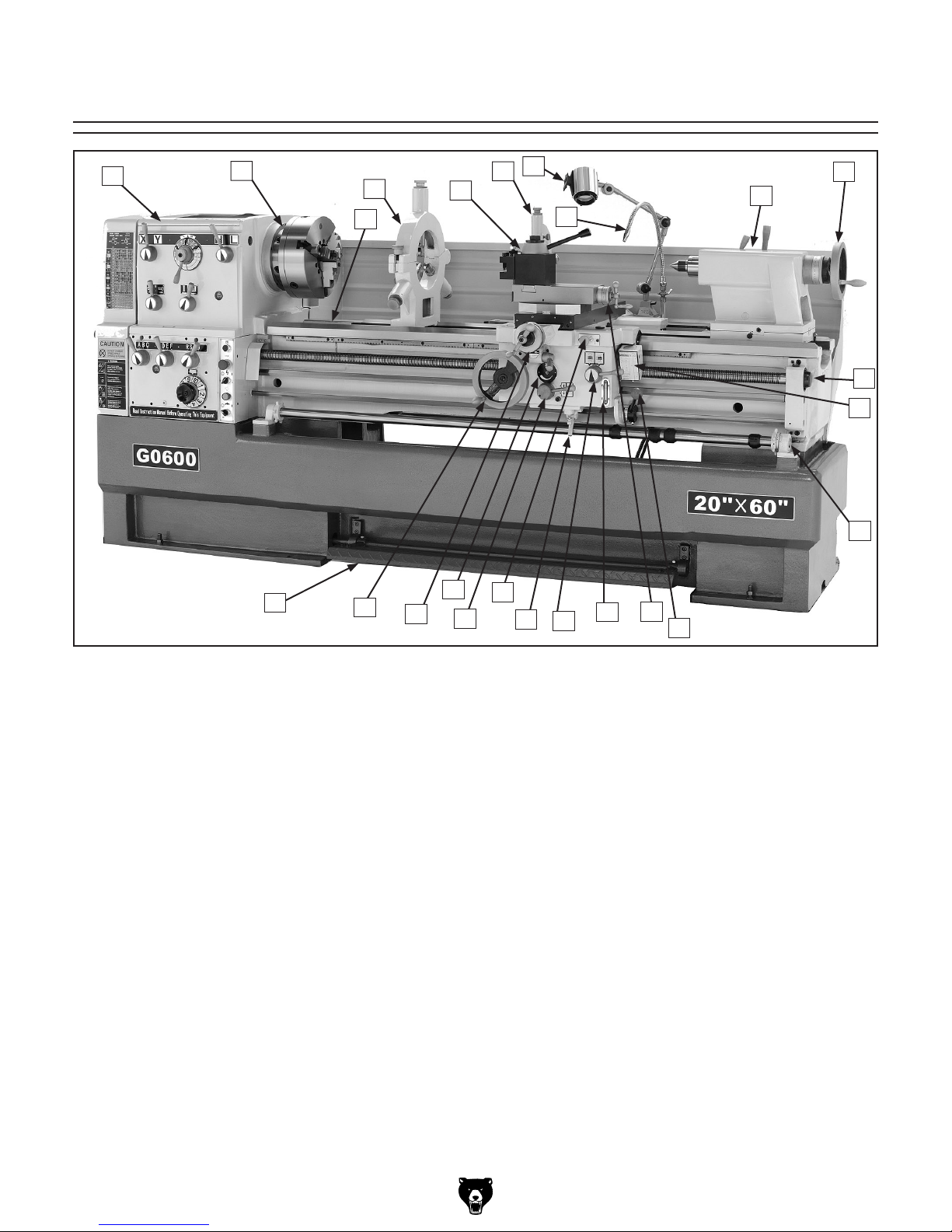

Identification ............................................................................................................................... 7

Headstock Controls .................................................................................................................... 8

SECTION 1: SAFETY ....................................................................................................................... 9

Additional Safety for Metal Lathes ........................................................................................... 11

Glossary of Terms .................................................................................................................... 12

SECTION 2: CIRCUIT REQUIREMENTS ...................................................................................... 13

220V 3-Phase .......................................................................................................................... 13

Operation .................................................................................................................................. 13

Phase Converter ...................................................................................................................... 13

SECTION 3: SETUP ....................................................................................................................... 14

Setup Safety ............................................................................................................................. 14

Items Needed for Setup ........................................................................................................... 14

Unpacking ................................................................................................................................ 14

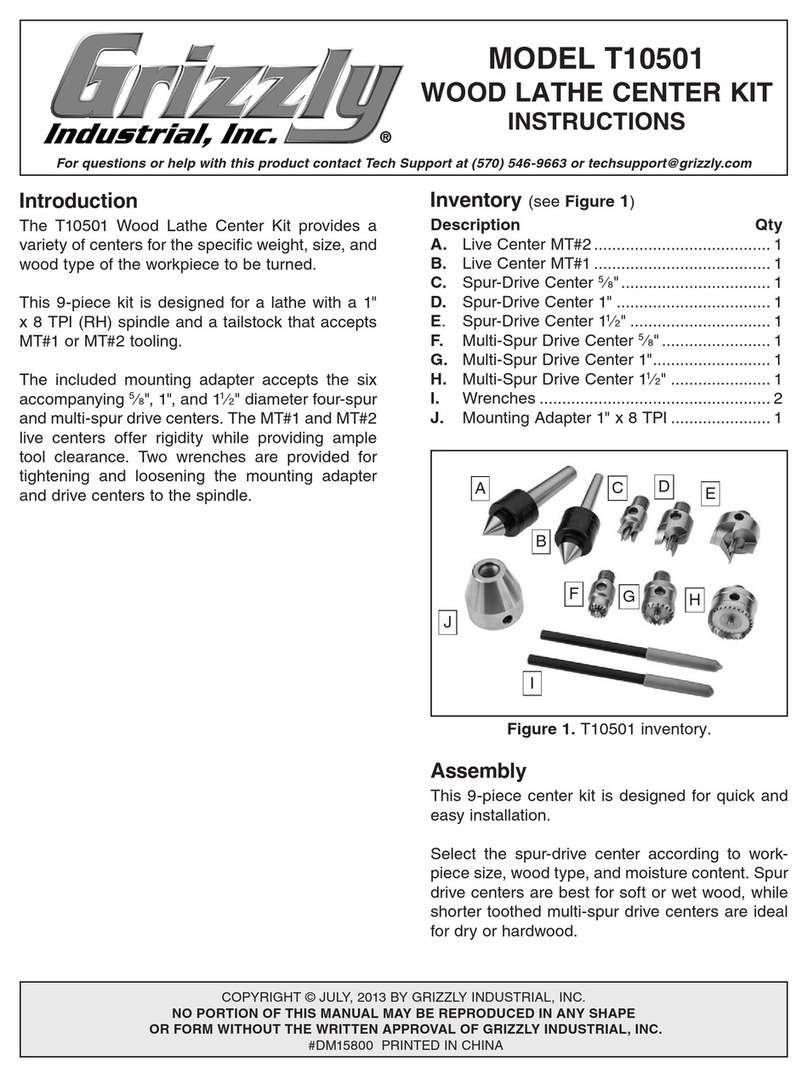

Inventory ................................................................................................................................... 15

Hardware Recognition Chart .................................................................................................... 16

Site Considerations .................................................................................................................. 17

Lifting & Moving the Lathe ....................................................................................................... 18

Cleanup .................................................................................................................................... 19

Test Run ................................................................................................................................... 20

Changing Motor Rotation ......................................................................................................... 22

Apron and Spindle Break-in .................................................................................................... 23

Spindle Balancing ................................................................................................................... 23

SECTION 4: OPERATIONS ........................................................................................................... 24

Operation Safety ...................................................................................................................... 24

General ..................................................................................................................................... 24

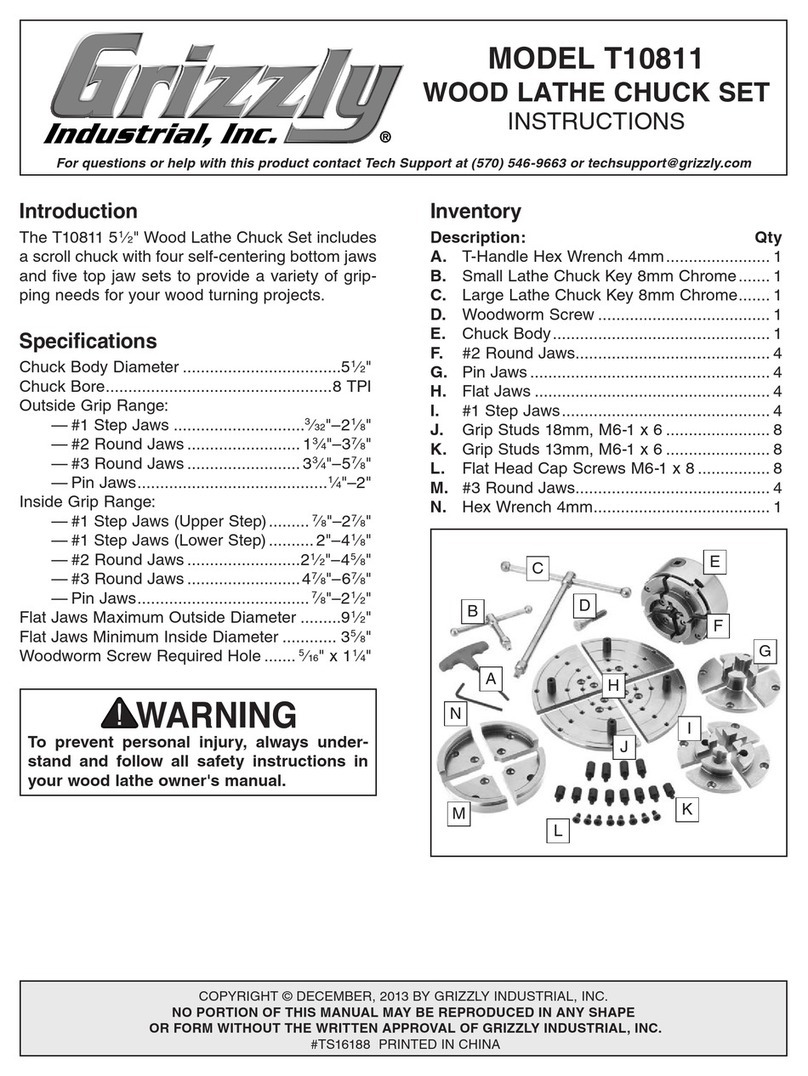

Chuck and Faceplate ............................................................................................................... 25

Mounting ................................................................................................................................. 25

Camlock Stud Adjustment ........................................................................................................ 27

Reversing Jaws ........................................................................................................................ 28

Gap Removal ........................................................................................................................... 29

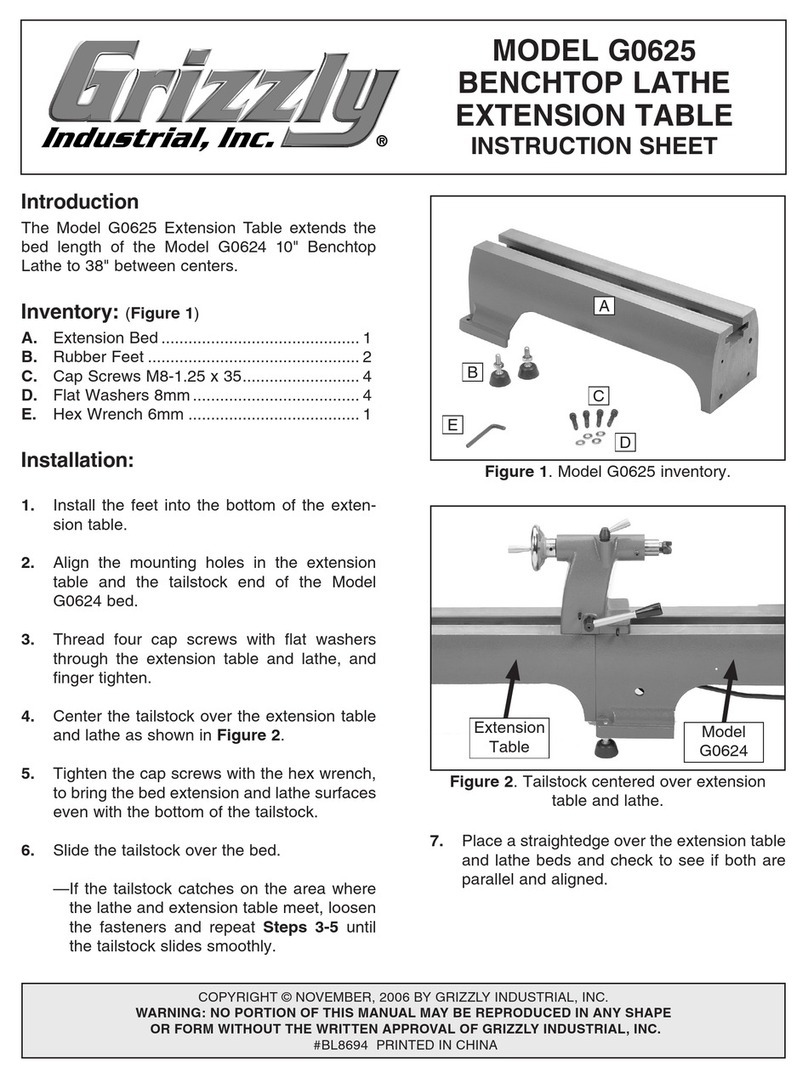

Tailstock ................................................................................................................................... 29

Aligning Tailstock ..................................................................................................................... 30

Drilling with Tailstock ................................................................................................................ 31

Cutting Tapers with Tailstock ................................................................................................... 31

Centers ..................................................................................................................................... 32

Steady Rest .............................................................................................................................. 33

Follow Rest .............................................................................................................................. 34

Setting Compound Slide .......................................................................................................... 34

Quick Change .......................................................................................................................... 35

Tool Post .................................................................................................................................. 35

Foot Brake ................................................................................................................................ 35

Setting Spindle RPM ................................................................................................................ 36

Manual Feed ............................................................................................................................ 38

Power Feed .............................................................................................................................. 38

Four-Position Apron Stop ......................................................................................................... 39

Starting Lathe ........................................................................................................................... 40

Using the Thread Chart ............................................................................................................ 41

Dimetrial and Modular Pitch Threading .................................................................................... 42

Inch and Metric Pitch Threading .............................................................................................. 44

Thread Dial ............................................................................................................................... 46