6 OM-AH/1E (CE) INTERNATIONAL

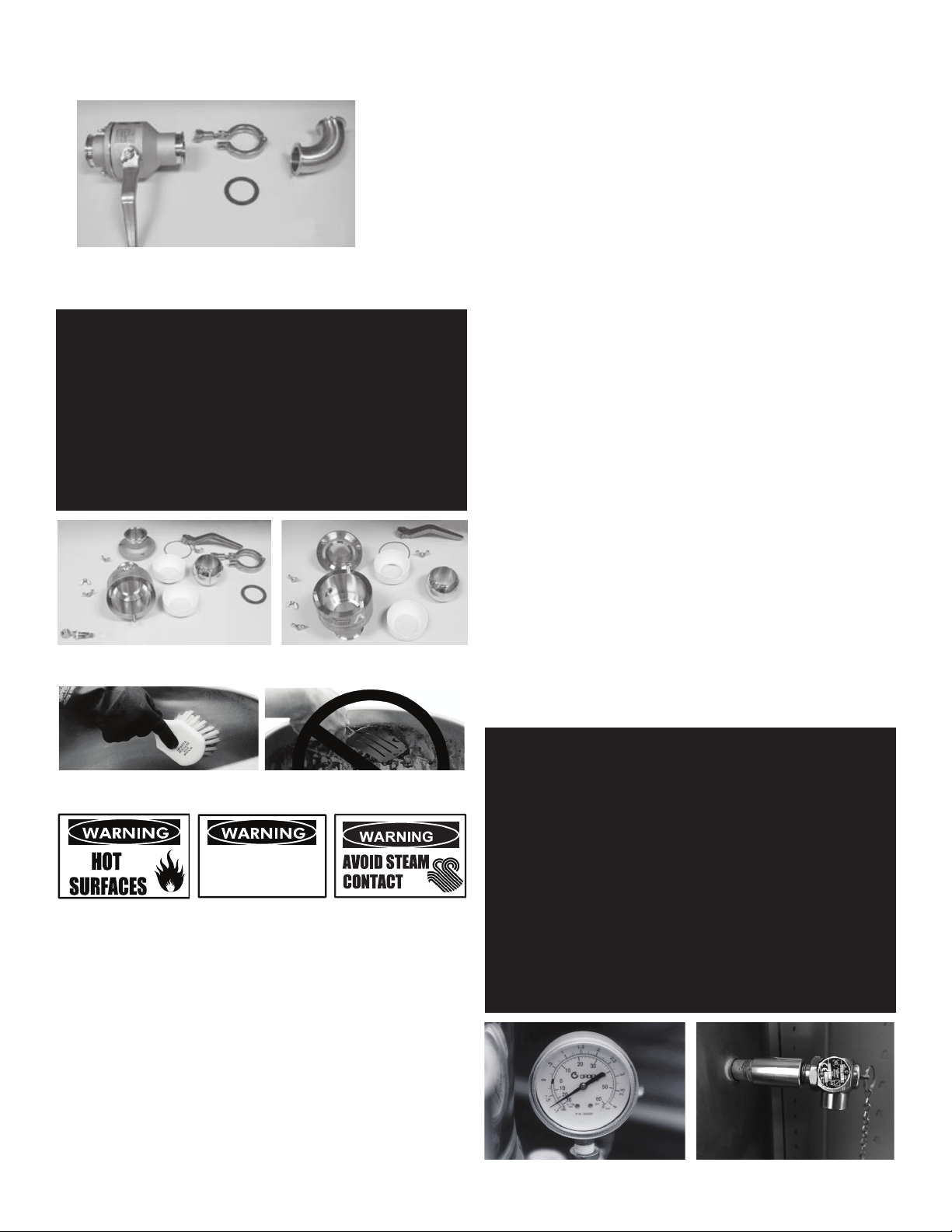

3. Ball Valve

Some kettles are equipped with an optional valve.

CLEANING

WARNING: KEEP WATER AND SOLUTIONS AWAY FROM CONTROLS AND ELECTRICAL

EQUIPMENT. NEVER SPRAY THE SUPPORT HOUSING OR ELECTRICAL

CONNECTIONS.

CAUTION: MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS

MEMBRANES, AND CLOTHING. PRECAUTIONS SHOULD BE TAKEN. WEAR

RUBBER GLOVES, GOGGLES OR FACE SHIELD, AND PROTECTIVE CLOTHING.

READ THE WARNINGS AND FOLLOW THE DIRECTIONS ON THE LABEL OF

THE CLEANER CAREFULLY.

CAUTION: NEVER LEAVE A SANITIZER IN CONTACT WITH STAINLESS STEEL SURFACES

LONGER THAN 30 MINUTES. LONGER CONTACT CAN CAUSE CORROSION.

WARNING: AVOID DIRECT CONTACT WITH HOT SURFACES. DIRECT SKIN CONTACT

COULD RESULT IN SEVERE BURNS.

Optional ball valves can be easily disassembled for cleaning.

Parts can be cleaned in standard sanitizer or dish washing.

Use a brush, sponge, cloth, plastic or

rubber scraper, or plastic wool to clean.

Don’t use metal implements

or steel wool when cleaning.

OM-TD

11

Don’t scrape with tools, steel wool or other

abrasives.

Use brushes, sponges or cloth to clean your

kettles

e) Allow hot water to fully drain from

product before moving the basket away

from the kettle. Do not rest the kettle

basket on the kettle rim or pouring lip. If

the basket is too heavy for one

individual to lift and safely move, get

help from another person. Remove

product immediately from the basket into

another container, being sure to avoid

contact with hot product and hot basket

or. . .

f) Place basket with food on stable, at

surface, setting it inside a solid steamer

or bake pan, to catch any remaining hot

water which might drain from product.

Cleaning

1. Suggested Tools:

a. A good cleaner.

b. Kettle brushes in good condition.

c. A good sanitizer.

d. Film remover.

CAUTION

MOST CLEANERS ARE HARMFUL TO THE

SKIN, EYES, MUCOUS MEMBRANES, AND

CLOTHING. PRECAUTIONS SHOULD BE

TAKEN. WEAR RUBBER GLOVES,

GOGGLES OR FACE SHIELD, AND

PROTECTIVE CLOTHING. READ THE

WARNI N GS AND FOLLOW T H E

DIRECTIONS ON THE LABEL OF THE

CLEANER CAREFULLY.

2. Procedure

a. Clean food-contact surfaces as soon as

possible after use. If the unit is in

continuous use, thoroughly clean and

sanitize the interior and exterior at least

once every 12 hours.

WARNING

AVOID ANY DIRECT CONTACT WITH HOT

SURFACES. DIRECT SKIN CONTACT

COULD RESULT IN SEVERE BURNS.

b. Scrape and ush out food residues. Be

careful not to scratch the kettle with

metal implements.

c. Prepare a hot solution of the detergent/

cleaning compound as instructed by the

supplier.

d. Clean the unit thoroughly, inside and

outside.

e. Rinse the kettle thoroughly with hot

water, then drain completely.

11

OM-TD

11

WEAR EYE

PROTECTION

WEAR EYE

PROTECTION

OM-TD

11

Don’t scrape with tools, steel wool or other

abrasives.

Use brushes, sponges or cloth to clean your

kettles

e) Allow hot water to fully drain from

product before moving the basket away

from the kettle. Do not rest the kettle

basket on the kettle rim or pouring lip. If

the basket is too heavy for one

individual to lift and safely move, get

help from another person. Remove

product immediately from the basket into

another container, being sure to avoid

contact with hot product and hot basket

or. . .

f) Place basket with food on stable, at

surface, setting it inside a solid steamer

or bake pan, to catch any remaining hot

water which might drain from product.

Cleaning

1. Suggested Tools:

a. A good cleaner.

b. Kettle brushes in good condition.

c. A good sanitizer.

d. Film remover.

CAUTION

MOST CLEANERS ARE HARMFUL TO THE

SKIN, EYES, MUCOUS MEMBRANES, AND

CLOTHING. PRECAUTIONS SHOULD BE

TAKEN. WEAR RUBBER GLOVES,

GOGGLES OR FACE SHIELD, AND

PROTECTIVE CLOTHING. READ THE

WARNI N GS AND FOLLOW T H E

DIRECTIONS ON THE LABEL OF THE

CLEANER CAREFULLY.

2. Procedure

a. Clean food-contact surfaces as soon as

possible after use. If the unit is in

continuous use, thoroughly clean and

sanitize the interior and exterior at least

once every 12 hours.

WARNING

AVOID ANY DIRECT CONTACT WITH HOT

SURFACES. DIRECT SKIN CONTACT

COULD RESULT IN SEVERE BURNS.

b. Scrape and ush out food residues. Be

careful not to scratch the kettle with

metal implements.

c. Prepare a hot solution of the detergent/

cleaning compound as instructed by the

supplier.

d. Clean the unit thoroughly, inside and

outside.

e. Rinse the kettle thoroughly with hot

water, then drain completely.

11

OM-TD

11

WEAR EYE

PROTECTION

WEAR EYE

PROTECTION

SUGGESTED CLEANING SUPPLIES

1. Cleaner, such as Klenzade HC-10 or HC-32 from ECOLAB, Inc. or equivalent.

2. Kettle brushes in good condition

3. Sanitizer such as Klenzade XY-12.

4. Film remover such as Klenzade LC-30.

PRECAUTIONS

Before cleaning, shut off the kettle by turning the main power switch to “OFF,” and

shut off all electric power to the unit at a remote switch, such as the circuit breaker.

PROCEDURE

1. Clean food-contact surfaces as soon as possible after use. If the unit is in

continuous use, thoroughly clean and sanitize the interior and exterior at least

once every 12 hours.

2. Scrape and flush out food residues. Be careful not to scratch the kettle with

metal implements.

3. Prepare a hot solution of the detergent/cleaning compound as instructed

by the supplier. Clean the unit thoroughly. A cloth moistened with cleaning

solution can be used to clean controls, housings, and electrical conduits.

4. Rinse the kettle and draw-off valve parts thoroughly with hot water, then drain

completely.

5. As part of the daily cleaning program, clean soiled external and internal

surfaces. Remember to check the sides of the unit and control housing,

underside of cover, etc.

6. To remove burnt on foods, use a brush, sponge, cloth, plastic or rubber scraper,

or plastic wool with the cleaning solution.To reduce effort required in washing,

let the detergent solution sit in the kettle and soak into the residue. Do NOT use

abrasive materials or metal tools that might scratch the surface. Scratches

make the surface harder to clean and provide places for bacteria to grow.

Do NOT use steel wool, which may leave particles in the surface and cause

eventual corrosion and pitting.

7. The outside of the unit may be cleaned with a warm water (100°F or less)

spray. Do not use a high pressure spray.

8. The outside of the unit may be polished with a stainless steel cleaner such as

“Zepper” from Zep Manufacturing Co.

9. When equipment needs to be sanitized, use a solution equivalent to one that

supplies 200 parts per million available chlorine. Obtain advice on sanitizing

agents from your supplier of sanitizing products.

10. It is recommended that each piece of equipment be sanitized just before use.

11. Clean the kettle thoroughly. If there is difficulty removing mineral deposits or a

film left by hard water or food residues, then use a de-liming agent, following

manufacturer directions.

12. Rinse and drain the unit thoroughly before further use.

13. If cleaning problems persist, contact your cleaning product representative for

assistance. The supplier has a trained technical staff with laboratory facilities

to serve you.

MAINTENANCE

WARNING: AVOID ANY EXPOSURE TO THE STEAM BLOWING OUT OF THE PRESSURE

RELIEF VALVE. SEVERE BURNS CAN RESULT ON EXPOSED SKIN. FAILURE

TO CHECK PRESSURE RELIEF VALVE OPERATION PERIODICALLY COULD

RESULT IN PERSONAL INJURY AND/OR DAMAGE TO EQUIPMENT.

CAUTION: KEEP GREASE AWAY FROM ELECTRICAL PARTS LOCATED NEAR THE

GEARS.

WARNING: TO AVOID INJURY, READ AND FOLLOW ALL PRECAUTIONS STATED ON THE

LABEL OF THE WATER TREATMENT COMPOUND.

WARNING: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY

THE MANUFACTURER OR THEIR AUTHORIZED DISTRIBUTORS CAN CAUSE

INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT AND WILL

VOID ALL WARRANTIES.

CAUTION: INSURE ELECTRICAL POWER IS REMOVED AND THE GAS IS TURNED OFF AT

THE SHUTOFF VALVE PRIOR TO PERFORMING ANY MAINTENANCE ON THIS

KETTLE.

WARNING: THIS KETTLE IS DESIGNED TO BE WATER RESISTANT. FAILURE TO FOLLOW

PROPER MAINTENANCE PROCEDURES MAY VOID THE WARRANTY.

The pressure gauge should show a vacuum of -20

to -30 inches of mercury (Hg) vacuum or a range of

-0.7 to -1.0 Bar when the kettle is cold.

The open end of the pressure relief valve

must face downward.