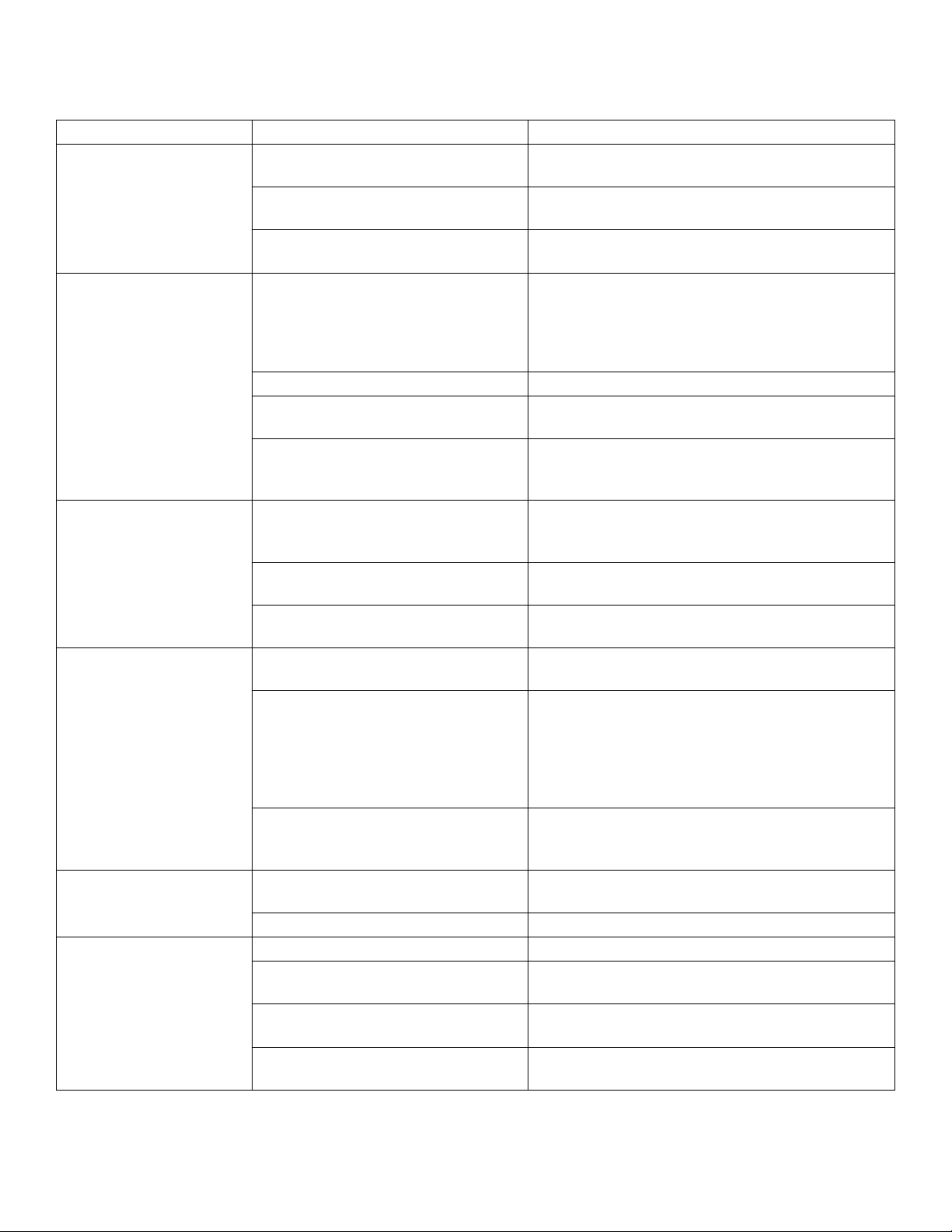

9

PROBLEM POSSIBLE CAUSE SOLUTION

The motor runs but

the pump will not prime

Themotorisrotatinginthewrongdirection

(thebatteryterminalsarereversed)

ReconnecttheREDclampto(+)terminal&BLACKclamp

to(-)terminalofbattery

TheBypassValve(11)isdirty/sticky InspectSpring(10)&BypassValve(11).

Clean/replaceifrequired

ThereisanairleakintheSuctionTube(38)

orfuelleakagefromthreadedjoints

InspectSuctionTube(38),hoses,jointsandre-sealwith

PTFETape(34)ifrequired

Pump discharge is low

Lowsupplyvoltage

1. Cleanthebatteryclamps&terminals.Ensurethatthe

supplyvoltageis12Vor24Vasperthepumpmodel

2. Checkwear&tearofMagnetAssembly(14),Armature

Assembly(15)&CarbonBrushAssembly(18).Replace

defectiveparts

Thetankisnotvented Ensurethatthetankisventedtoatmosphere

ThereisanairleakintheSuctionTube(38)

orfuelleakagefromthreadedjoints

InspectSuctionTube(38),hoses,jointsandre-sealwith

PTFETape(34)ifrequired

TheFuelControlNozzle(28)orsuctionline

isblocked

1. Ensurethatthestrainer/filter/hose/nozzleisclean

2. EnsurethattheSuctionTube(38)isatleast25mm

abovethebottomoftank&fuellevelisnottoolow

The motor stalls when the

nozzle is closed

Lowsupplyvoltage

1. Cleanthebatteryclamps&terminals.Ensurethatthe

supplyvoltageis12Vor24Vasperthepumpmodel

2. Checkmotor&replaceifitisfaulty

TheBypassValve(11)isdirty/sticky InspectSpring(10)&BypassValve(11).

Clean/replaceifrequired

StickingVanes(4) EnsuretheVanes(4)slidefreelyinsidetheRotor(6).

ReplaceVanesifrequired

The switch will not turn ON

the pump

Blownfuse OpenfusecoverlocatedinBatteryCable(26).

Replaceblownfuse(15Amp)

DefectiveRockerSwitch(25)

CheckRockerSwitch(25)andreplaceitiffaultyasperthe

followingsteps:

1. LoosenthreeSlottedHeadScrews(24).

2. RemoveSwitchCover(23)afterdisconnectingthe

couplerattachedtoit.GrabthelockingclipsofRocker

Switch&pushoutwardstoremoveit.

Damagedordefectivemotor

Checkwear&tearofMagnetAssembly(14),Armature

Assembly(15)&CarbonBrushAssembly(18).

Replacemotorassemblyifneeded.

Fuel leakage

Pumpoperatingtimeextendedwithnozzle

closed Donotexceed5minutesofoperationwithnozzleclosed

ArmatureshaftwornfromRotorside ReplaceMotorAssembly

Motor overheating

StickingVanes(4)orRotor(6)binding ChecktomakesureVanes&Rotorturnfreelyonshaft

Pumpoperatingtimeextendedwithnozzle

closed

Donotexceed5minutesofoperationwithnozzleclosed

TheFuelControlNozzle(28)orsuctionline

isclogged

Inspectandcleanifrequired

Pumpoperatedformorethan30minutes

continuously

Limitoperationto30minutesperhour

TROUBLESHOOTING

(Refer to EXPLODED VIEW - Page 6)

Table 5