USING FUEL FILTER WITH PUMP

This pump is designed for use with a Fuel Filter.

This can be done by connecting the pump outlet direct to the Fuel Filter, using a straight steel extn.

Note: Pump outlet is threaded ¾” BSPT (F)

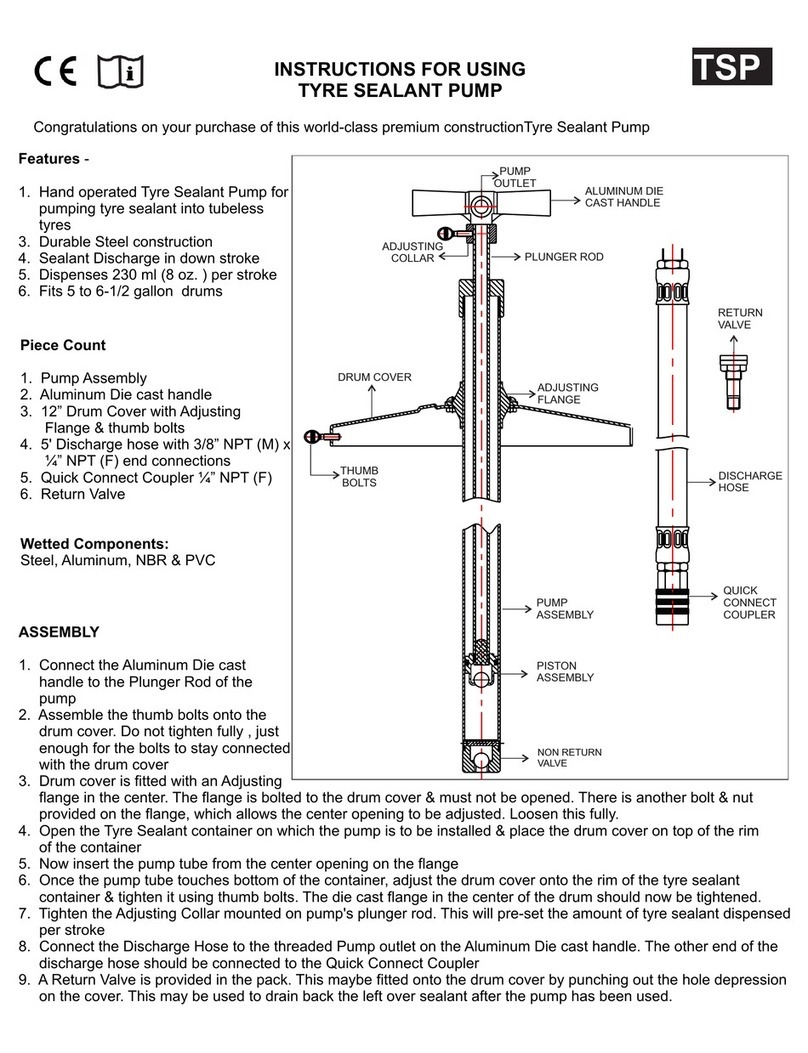

5. Tighten the suction tube onto the pump inlet. It is good practice to use a sealant such as Teflon in connecting

the suction tube to the pump inlet

6. Insert the pump assembly into the drum from the 2” bung opening on the drum

7. Once the bottom of the suction tube touches the base of the drum, securely fasten the bung onto the drum.

Now tighten the bung onto the suction tube

8. When using the pump for the first time or after an extended period of time or using the pump to lift Fuels/ Low

Viscosity Media; make sure to Prime before use. To Prime, POUR 30 ML OF MEDIA BEING PUMPED/ OIL

INTO THE PUMP OUTLET. RAPIDLY ROTATE THE PUMP HANDLE TILL PUMP STARTS DISPENSING.

In everyday use ,it may take about 10 rotations of the crank for pump to start dispensing

9 . When not in use, you may chose to lock the pump using a padlock. Crank has a link under it which fits onto

the Lock Latch on the pump body.

10. For Pump Models supplied with hose assembly, you may use the nozzle holder, located adjascent the crank

& crank shaft connection to store the hose when not in use

CAUTION:

No

smoking Safety gloves

must be worn

Wear your

safety glasses

Safety overalls

must be worn

1. Use of this equipment to pump fluids other than approved will void the manufacturing warranty

2. Never open the pump Assembly.

3. This pump is NOT U/L approved. If local laws do not allow for Fuels to be pumped using Non U/L approved pumps; you must

not use this pump for dispensing fuel.

4. This is a Rapid Action Pump & dispenses very large amount of media with each rotation. Be careful not to over dispense. It is also

recommended to lock the crank when not in use, as even slight un-intentional rotation will cause a lot of discharge

5. Never operate the pump near fire or source of spark. Some Media may be Explosive & Hazardous

6. Pump should only be used in well-ventilated areas. Never fill containers in confined areas, e.g. inside a vehicle. Do not operate pump in

areas where vapours can accumulate

7. Precautions are necessary to minimize the build-up of static charge, which could cause sparking

8. Always use Genuine anti-static hose when pumping petrol and other flammable liquids.

9. Fuel storage tanks and drums should be metal and grounded to earth. Ensure the floor or ground where fuel is stored or dispensed is

and remains electrically conducive

10. Wear anti-static or conductive footwear and avoid wearing silk and/or synthetic clothing, unless treated with anti-static solution

11. Avoid prolonged skin contact with petroleum products. Use of protective goggles, gloves and aprons is recommended in case of

accidental splashing or spillage. Change clothing and wash skin contact areas promptly with soap and water

12. When carrying out maintenance of this pump, for your own protection, thoroughly drain the pump and hose before disassembly. Clean

flammable liquids from components as they are removed from the pump. Follow precautions when handling flammable liquids

TROUBLESHOOTING

Pump does not dispense fluid

PROBLEM CAUSES REMEDYSr. Nr

1. 1.Pump not able to create adequate suction

2.Pump is drawing in air instead of fluid

3. Crank is not connected to crank shaft

1. Prime pump. Follow Step 9 above

2. Tighten all connections of suction tube

& of the suction tube with pump inlet

3. Loosen the grub screw on the crank.

Now align it with the depression on the

crank shaft & then tighten

Leakage of media from the

crankshaft

2. Damaged seal due to use with media

not suitable for use with pump

Seal needs to be replaced. Send to

distributor for service repair

Leakage of media from between the

cover plate & pump body

3. Damaged seal due to use with media

not suitable for use with pump

Seal needs to be replaced. Send to

distributor for service repair

S1240, Rev-D