3 PB

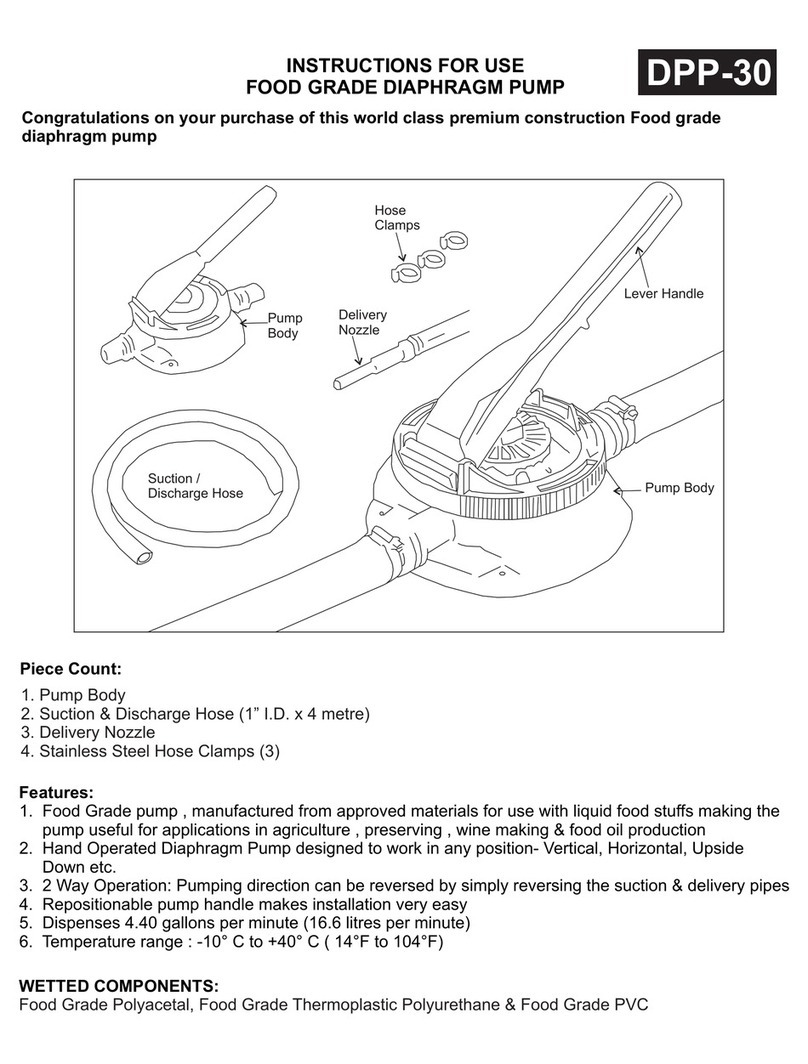

3. Assemble the

filter (3) on the

suction hose and

fasten in place

with a hose

clamp.

4. Screw the pump

body (1) onto

the drum or tank,

taking care to

place the pump in

a vertical position.

5. Assemble the delivery

hose onto the delivery

nozzle of the pump

body and fasten the

bent spring over the

delivery nozzle with a

clamp as described

on the “Bent Spring

Device” instruction

sheet.

6. Assemble the

dispensing nozzle

(3) onto the

opposite end of the

delivery hose and

fasten in place with

a hose clamp.

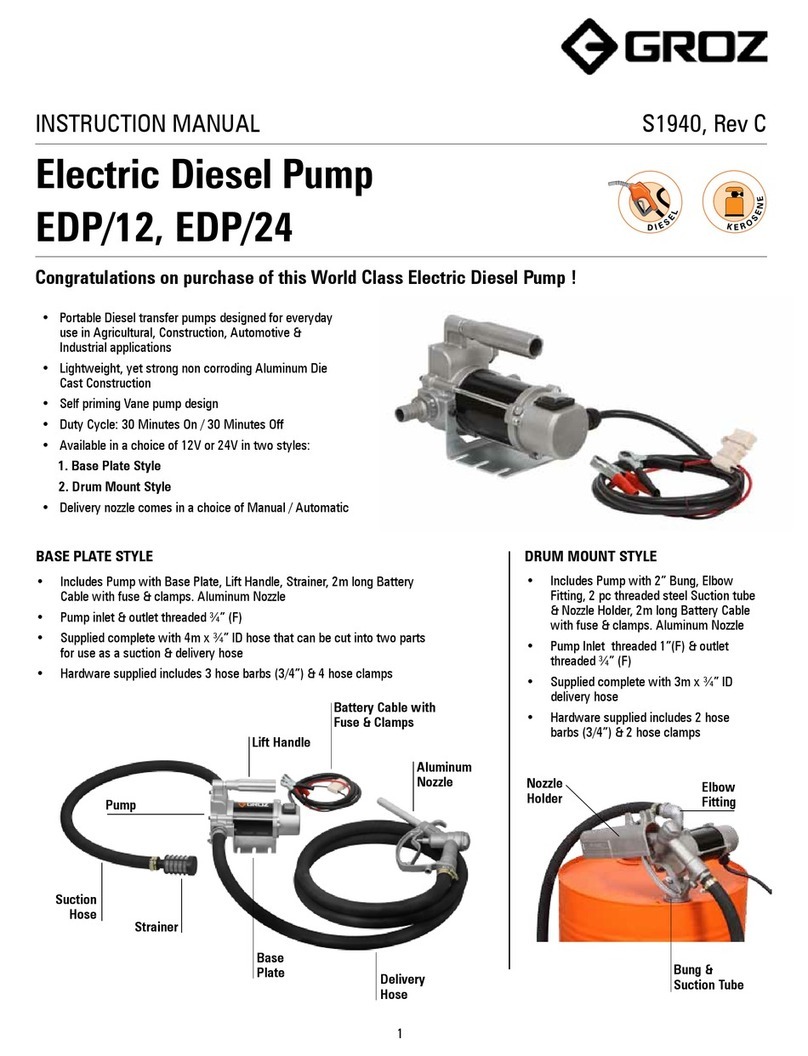

• The motor and switch are not of an anti-explosive type. Do

not use the pump in areas where there is risk of explosion.

• Do not use the pump for gasoline, inflammable liquids with

PM < 55° C, Food Liquids, Corrosive Chemical Products and

Solvents.

• Do not smoke or use open flame during refuelling.

• Avoid spilling diesel, which is harmful to the environment.

• Never operate the pump when empty.

• Do not leave the motor running under delivery in closed

condition ( i.e when the Trigger (9) is not pressed ) for

more than five minutes .

• The pump only works in a vertical position.

• The pump must only be used under the surveillance of the

operator

• Before connecting the pump to the power supply, ensure

that the voltage complies with the limitations indicated.

Power that is out of specified limits can damage the electrical

components.

Max. acceptable variation = +/- 5% of the nominal value

1. PRIMING PROCEDURE :- Open the nozzle by pressing the

trigger (9). Start the pump by repeatedly activating the lever

(8) until the liquid starts flowing from the dispensing nozzle.

2. When fluid starts flowing out, start the motor using the

switch (10) and proceed to fuelling.

3. When finished, release the Trigger and switch off the motor.

COMMISSIONING AND USE

The operator must repeat “PRIMING PROCEDURE” under

the following situations -

• After an extended stop,

• If liquid does not flow,

• If the motor is re-started

• After a power failure.

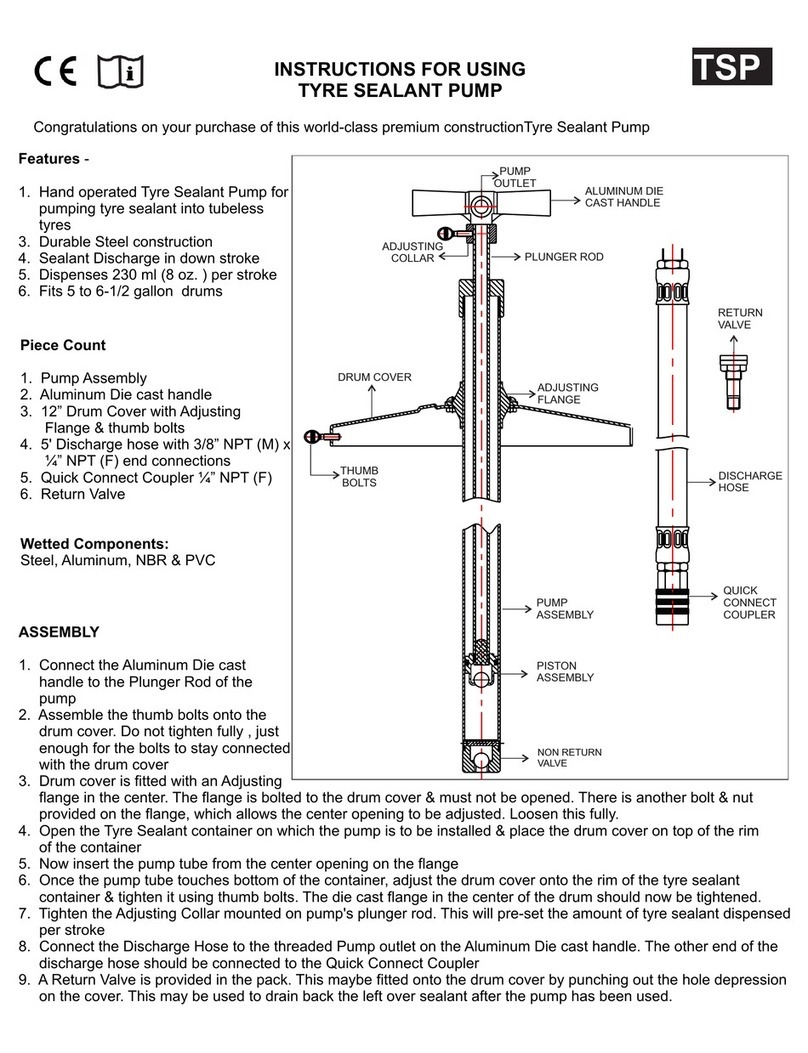

Bent

Spring

Device

Straight end of the bent spring should be oriented

to the top of the pump and held by the clamp

7. Now connect the pump to power source .