English (GB)

7

4. Safety

4.1 General safety instructions

5. Transportation, delivery and storage

5.1 Transportation

The individual components of the pump must be packed carefully

to prevent any damage to the surface protection during

transportation.

All lifting equipment must be rated for the purpose and checked

for damage before any attempts to lift the components are made.

The lifting equipment rating must under no circumstances be

exceeded.

5.2 Delivery

On delivery, the pump and any accessories supplied with it

should be checked for transport damage. This also applies when

the equipment is delivered to the installation site.

If the pump or any accessories have been damaged during

transportation, contact your local Grundfos company before

continuing to install the equipment. Do not dismantle a damaged

new component for further inspection, unless instructed by your

local Grundfos company.

The packaging material must be disposed of according to local

regulations.

5.3 Storage

The pump must be stored in a dry location in which the

temperature is not subject to major fluctuations.

If the pump has been stored for more than one year, the gearbox

oil must be changed. The oil must be changed even if the pump

has never been in use. This is necessary because of natural

aging of mineral oil lubricants.

6. Installation

During installation, the pump must only be lifted when using the

suspension point.

The lifting equipment supplied with the pump as well as the wire

used for lifting and lowering the pump into the tank must not be

used as universal lifting equipment.

6.1 Positioning

Correct positioning of the pump is essential to ensure trouble-free

operation and long life. The following guidelines must be

observed:

• If more pumps are installed in the same tank, they must not

generate opposite flows.

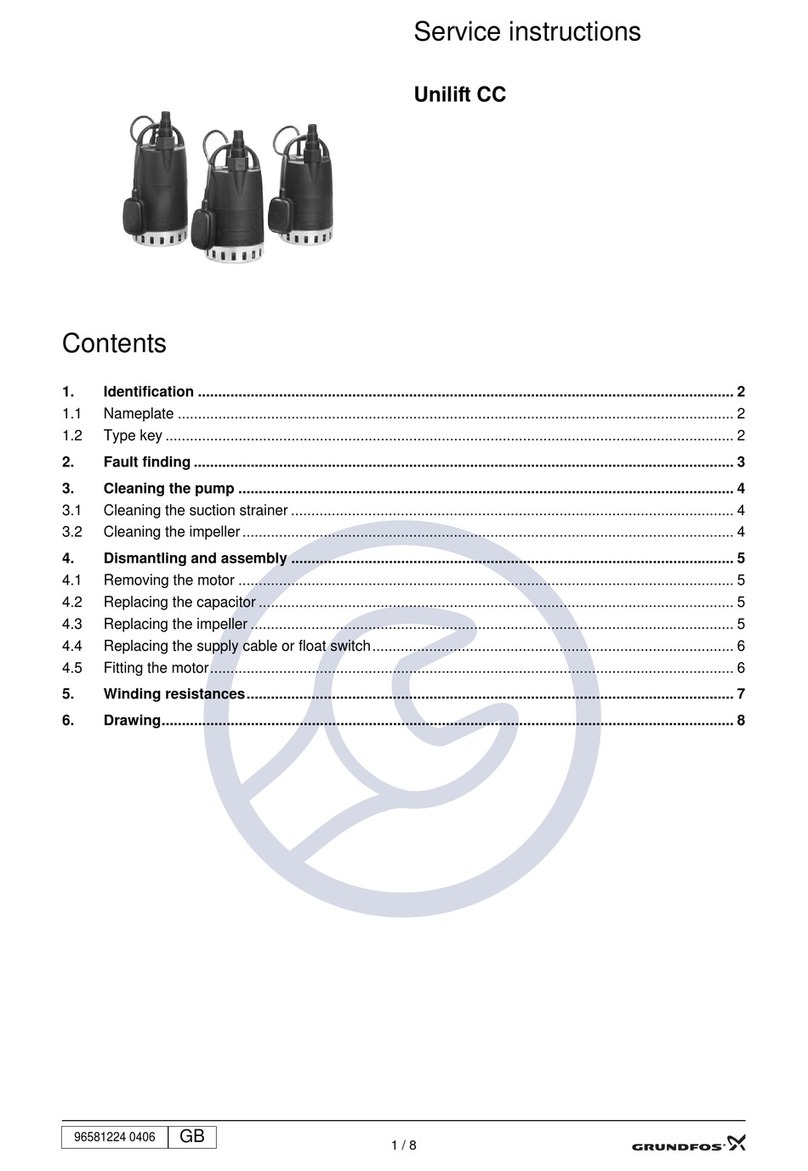

• The distance from the centre of the pump to the tank bottom

(Hmin) must be equal to the impeller diameter. See fig. 3.

• The distance from the top of the pump rack to the liquid

surface (HABOVE) must fulfil one of the following two

requirements:

– For pumps with vortex shield, the distance must at least be

equal to the impeller diameter.

– For pumps without vortex shield, the distance must at least

be equal to 1.5 times the impeller diameter. See fig. 3.

Fig. 3 Distance to liquid surface and tank bottom

Warning

Before starting work on the product, make sure

that the fuses have been removed or the mains

switch has been switched off. Make sure that the

power supply cannot be accidentally switched

on.

Warning

These safety instructions as well as the

instructions in each individual section must be

followed when transporting, storing, handling

and operating the pump.

The pump must be installed, connected, started

up and serviced by qualified persons.

Beware of rotating parts.

Make sure that persons cannot accidentally fall

into the tank, e.g. by installing a cover or railing.

Warning

Make sure that the pump cannot roll or fall over.

Warning

Before attempting to lift or otherwise handle the

individual components of the pump, observe any

local regulations that set limits for the weight of

the components to be lifted manually by

individuals, i.e. handled without the use of lifting

equipment.

Warning

A damaged pump must not be installed.

Never hang the pump by the supply cable.

Never let the pump run while hanging in the

lifting equipment.

TM02 9478 2704

Hmin HAbove