9

English (GB)

8. Preliminary checks

Before the commissioning check that:

• the pumping set corresponds to what was ordered and that

accessories, if any, are not missing,

• the packing is intact,

• the system voltage is the same as that of the mains,

• the installation room dimensions are adequate for the set to

install,

• the room has the proper air circulation,

• the system operating conditions comply with what is stated in

the dedicated paragraph.

9. Installation

Note that, with respect to the installation room

and specically for the construction works,

ventilation, air exchange, the evacuation of

exhaust fumes of the engine and the power

supply system, please refer to the system de-

sign. The timely execution in compliance with

regulations and provisions, should be done by

specialists appointed by the client, who take a

particular responsibility.

The EN 12845 and UNI 11292 standards provide the guidelines

regarding installation of the pumping sets that in any case are to

be integrated in observance of the re-ghting system regula-

tions, local provisions and good workmanship practices in force.

9.1 Foundation and anchorage

The following are general guidelines are in-

tended as suggestions. The design and execu-

tion must be properly carried out in accordance

with the relevant standards and regulations by

specialists commissioned by the client, who

will assume specic responsibility for the work.

Incorrect or not lasting anchorage may cause

serious damage to the pumping set or even to

the and the system.

The pumping set Hydro EN must be placed on a at surface

such as a oor or a concrete foundation.

The support base frame must be suciently heavy to ensure a

permanent support for the entire pumping set and must be able

to absorb any vibration, normal mechanical stresses or shocks.

As a rule of thumb, the weight of the concrete foundation should

be 1,5 times the weight of the pump set.

The dimensions of the foundation must be larger than the size

of the pumping unit that will have to accommodate.

The fastening must ensure tightness over time and have

characteristics such as to withstand the vibration of the system

during its operation.

Are not generally accepted dowels vibration dampers to x the

pumping set baseframe on the ground and should be carefully

evaluated fastening systems in areas with seismic characteris-

tics.

9.2 Installation room - ventilation and dimensions

The Hydro EN pumping units must be installed in a weather-

proof room protected against freezing that is well ventilated

to ensure that the electric motors and the diesel engines are

satisfactorily cooled:

Ambient T (min.): > +4°C for sets with electric pumps

> +10°C in the case of sets with diesel pump

Ambient T (max): < +40°C with pumps running at maximum

load and in any ambient condition.

Pay attention to correct evacuation of the diesel engine exhaust

fumes, for which an adequate ducts must be installed.

The installation room of the pump unit must be suitably sized

according to current regulations, local regulations, good work-

manlike manner and taking into account:

• the overall dimensions of the pumping set,

• ease of access to the parts of the set both for the commis-

sioning, routine checks and maintenance,

• the need to have an adequate exchange of air within the

room to ensure a correct cooling of the machines.

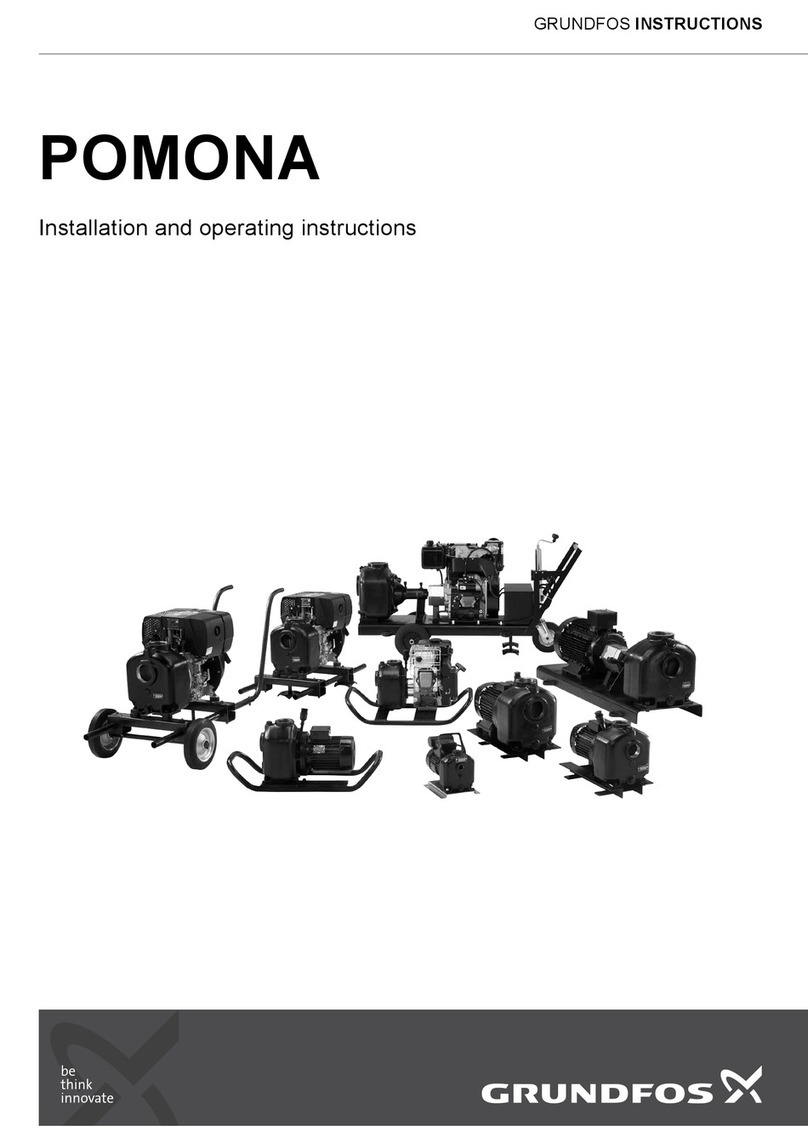

The pictures below give an indication of the minimum free space

to leave around the pumping set.

When sizing room openings for eective air

exchange, also consider the place of installa-

tion and the presence of other machines or heat

sources in the same room.

The installation of motors in closed environments always

requires appropriate recirculation of fresh air in the room in

order to ensure elimination of the heat generated during opera-

tion and adequate cooling of the machinery.

Openings and ventilation ducts for hot air expulsion, should

generally be dimensioned to means of analytic calculation.

9.3 Diesel pumps with direct air cooling

A fan (driven by the engine itself), generates an air ow that is

conveyed on the motor and ensures cooling. The heat is then

released into the environment and must be extracted from the

room.

9.4 Diesel pumps with water/water heat exchanger

cooling

In the pumping sets of the Hydro EN series, for liquid cooled

engines, the engine cooling is operate through a water/water

heat exchanger with expansion tank.

With this system the engine is cooled by the water of the re-

ghting system.