The companies of the STAUFF Group assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information,

product or process disclosed in this document.

Reference herein to any specic commercial product, process, service by trade name, trademark, manufacturer, or otherwise, does not constitute or

imply its endorsement, recommendation, or favouring by STAUFF.

Subject to change without prior notication.

Content

1. Overview .......................................................................................................................................................................................................................6

2. Oil Quality Index.............................................................................................................................................................................................................7

2.1. Introduction............................................................................................................................................................................................................7

2.2. Oil Degradation ......................................................................................................................................................................................................7

2.3. OQI Value vs Loss Factor Percentage ......................................................................................................................................................................7

2.4. Traffic Lights ..........................................................................................................................................................................................................7

2.5. Numbering/Levels ..................................................................................................................................................................................................7

2.6. Clean Point (Start Point)..........................................................................................................................................................................................8

2.7. Loss Factor Percentage and OQI Value....................................................................................................................................................................8

2.8. Scaling ..................................................................................................................................................................................................................8

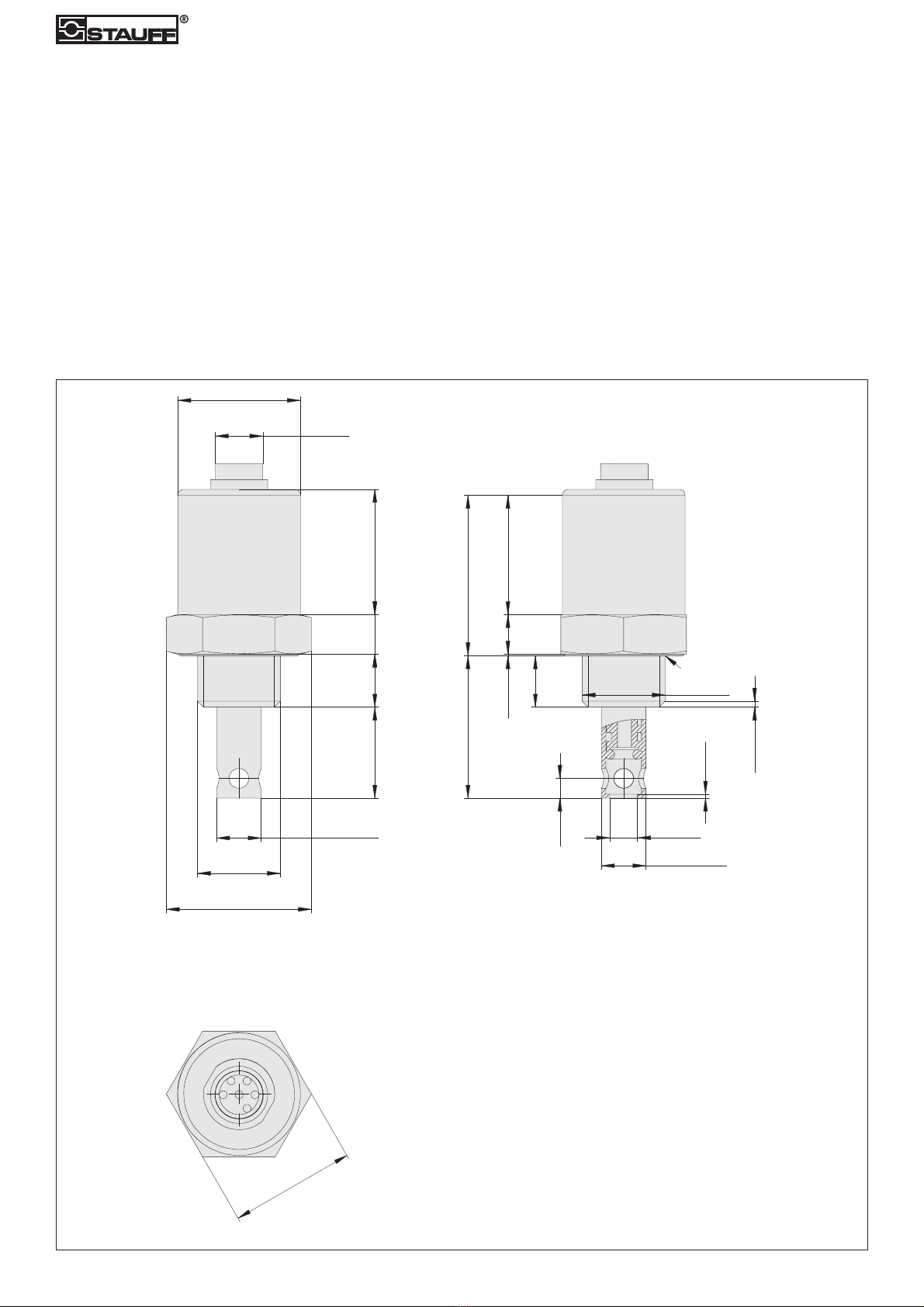

3. Oil Condition Sensor Type OCS - Technical Data .............................................................................................................................................................9

3.1. Safety Notes...........................................................................................................................................................................................................9

3.2. Dimensions ............................................................................................................................................................................................................9

3.3. Mechanical Installation..........................................................................................................................................................................................10

3.4. Precautions ...........................................................................................................................................................................................................10

3.5. Choosing the Sensor Mounting Location................................................................................................................................................................10

3.6. Fitting Method – Summary ....................................................................................................................................................................................10

3.7. Cleaning and Maintenance ....................................................................................................................................................................................10

4. Oil Condition Sensor Type OCS - Electrical Specifications ..............................................................................................................................................11

4.1. Electrical Installation .............................................................................................................................................................................................11

4.1.1. Power Supply.............................................................................................................................................................................................11

4.1.2. Wiring Diagram..........................................................................................................................................................................................11

4.2. 4 ... 20 mA Output.................................................................................................................................................................................................12

4.2.1. Sensor Output............................................................................................................................................................................................12

4.2.2. Oil Condition ..............................................................................................................................................................................................12

4.2.3. Oil Temperature .........................................................................................................................................................................................13

4.2.4. Sensor Calibration .....................................................................................................................................................................................13

4.3. RS485 Communications ........................................................................................................................................................................................13

2www.stauff.com

STAUFF OCS-Manual-EN.indd 2 18.06.2014 10:27:57