i

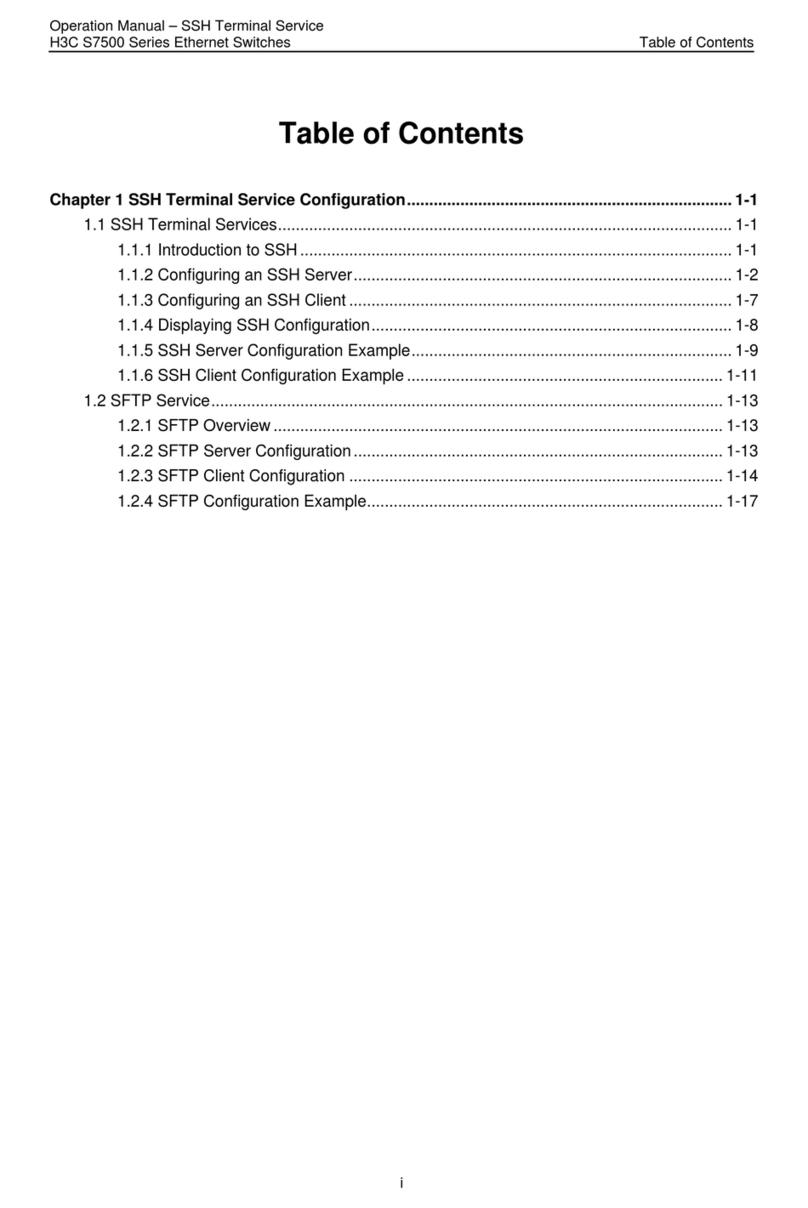

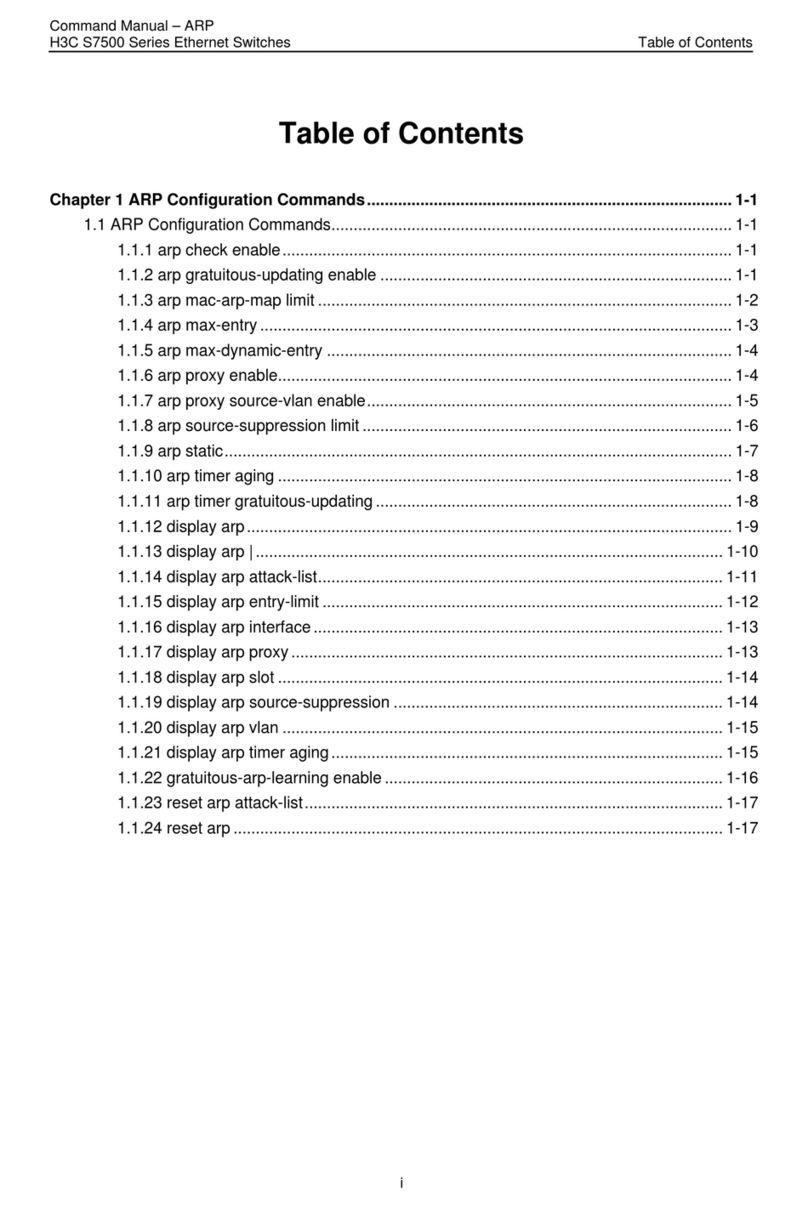

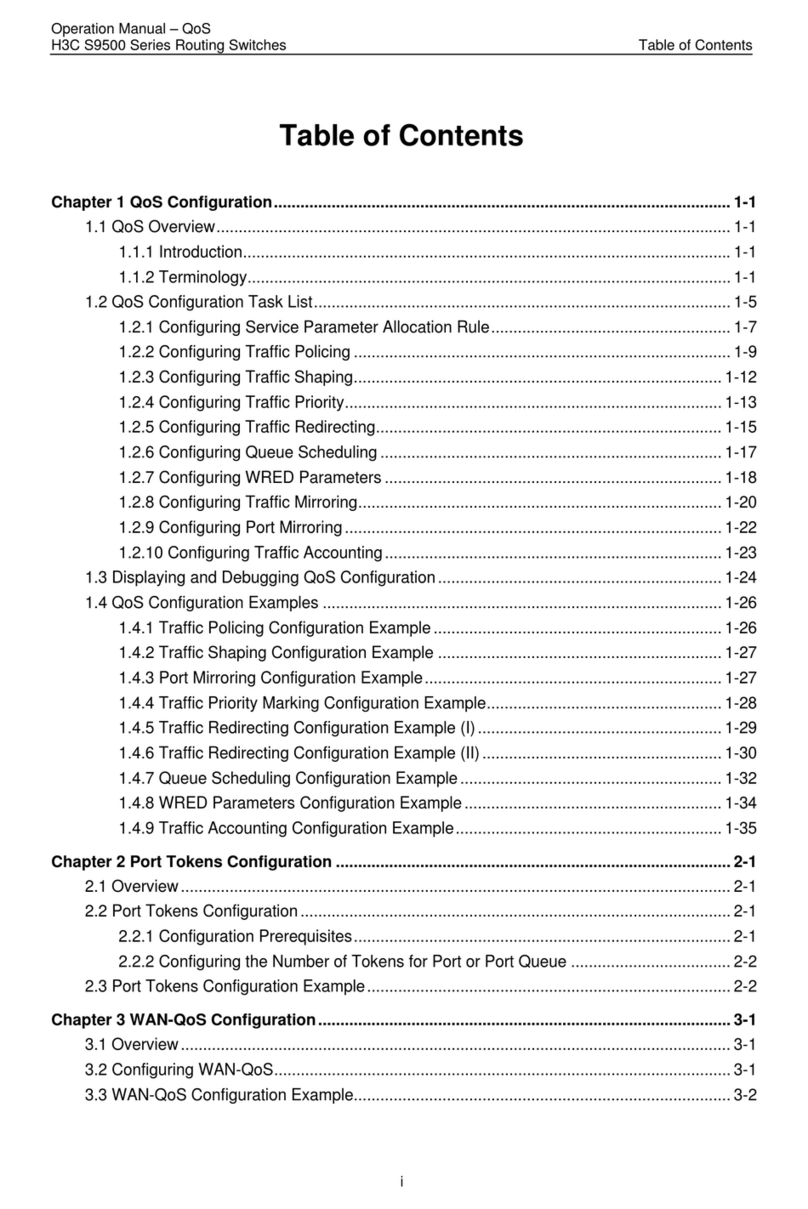

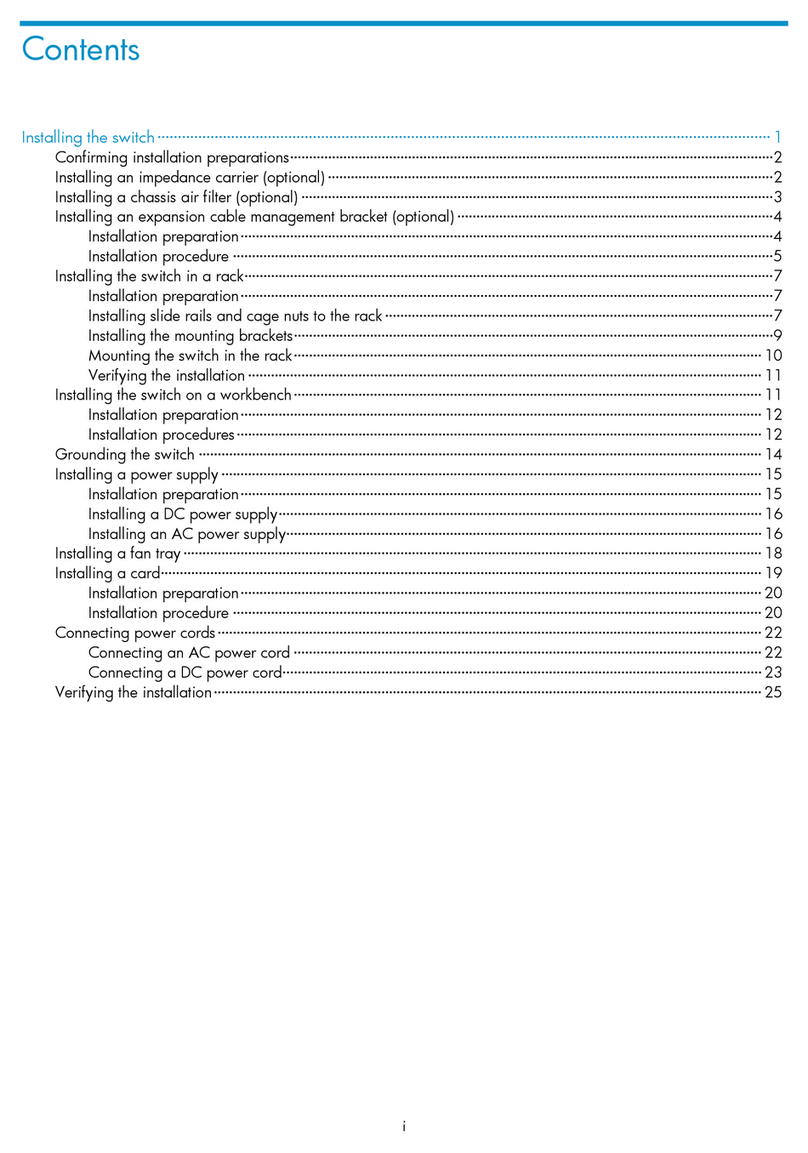

Contents

1 Preparing for installation··········································································1-1

ESD prevention···············································································································································1-1

Examining the installation site·························································································································1-1

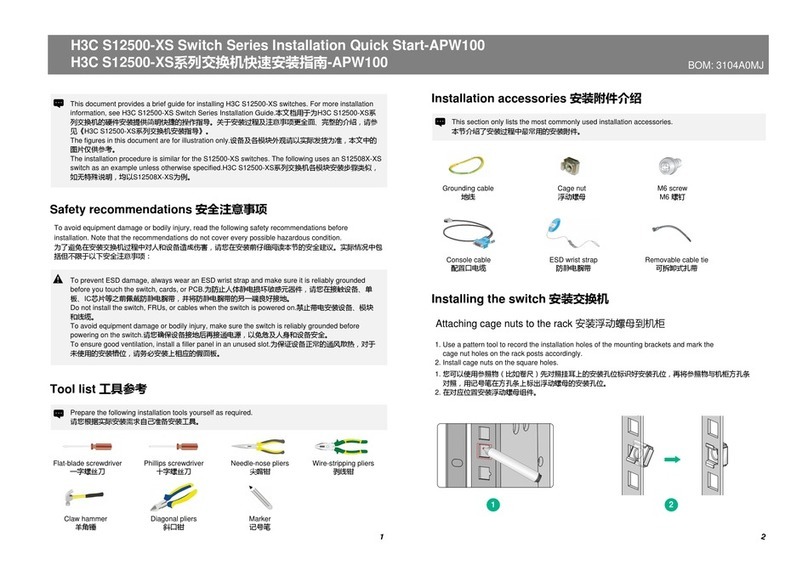

Installation tools and equipment ·····················································································································1-1

2 Installing the switch··················································································2-1

Switch dimensions ··········································································································································2-1

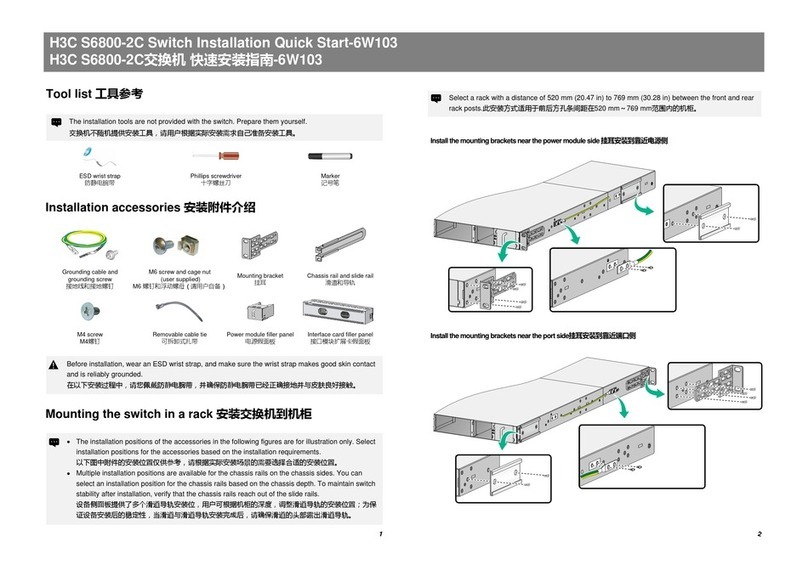

Rack requirements··········································································································································2-1

Slide rail requirements ····································································································································2-1

Installing slide rails··········································································································································2-2

Installing cage nuts for attaching mounting brackets······················································································2-3

Mounting the switch in a rack··························································································································2-4

Grounding the switch ······································································································································2-5

3 Installing removable components·····························································3-1

Attaching an ESD wrist strap ··························································································································3-1

Installing and removing SEUs·························································································································3-1

Installing an SEU·····································································································································3-1

Removing an SEU···································································································································3-2

Installing and removing interface modules······································································································3-3

Removing the protective blank panel······································································································3-3

Installing an interface module ·················································································································3-3

Removing an interface module ···············································································································3-4

Installing a filler panel in an empty interface module slot········································································3-5

Installing cable management brackets····································································································3-5

Installing and removing fan trays ····················································································································3-6

Installing fan trays···································································································································3-6

Removing a fan tray································································································································3-7

Installing and removing power supplies··········································································································3-8

Installing a power supply·························································································································3-8

Removing a power supply·······················································································································3-9

Connecting the power cord·····························································································································3-9

Connecting the AC power cord···············································································································3-9

Connecting the DC power cord·············································································································3-10

(Optional) Installing a DC input terminal block······························································································3-11

(Optional) Installing transceiver modules······································································································3-12

Installing a QSFP+/QSFP28 transceiver module··················································································3-13

Connecting a QSFP+/QSFP28 cable····································································································3-13

4 Cabling recommendations·······································································4-1

Routing network cables···································································································································4-1

Routing power cords·······································································································································4-1

5 Accessing the switch ···············································································5-1

Connecting the console cable·························································································································5-1

Verification before login···································································································································5-1

Viewing switch startup information··················································································································5-2