1-1

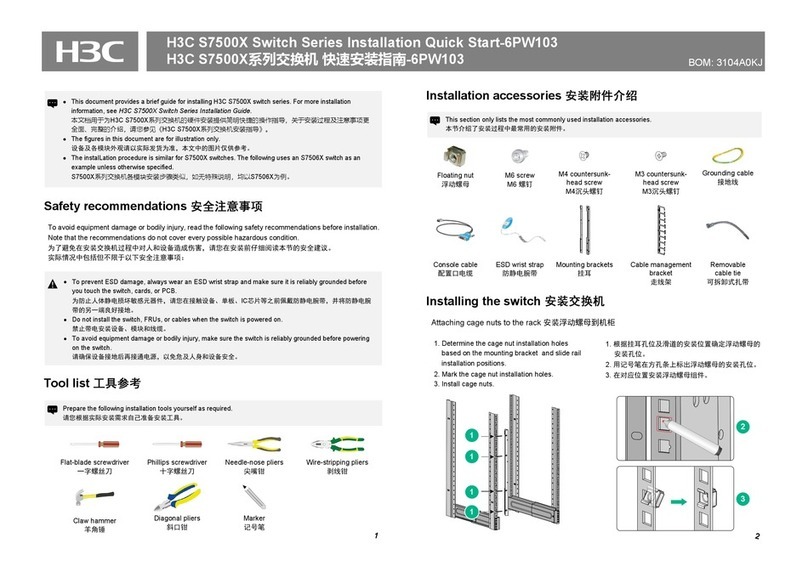

1 Preparing for installation

Safety recommendations

To avoid possible bodily injury and equipment damage, read Compliance and Safety Manual

provided with the switch and all safety recommendations in this chapter carefully before installation.

The recommendations do not cover every possible hazardous condition.

General safety recommendations

Keep the switch clean and dust-free.

Do not place the switch on a moist area, and avoid liquid flowing into the switch.

Make sure the ground is dry and flat and anti-slip measures are in place.

Keep the switch and installation tools away from walk areas.

Do not wear loose clothing, jewelry (for example, necklace) or any other things that could get

caught in the switch when you install and maintain the switch.

Electricity safety

Clear the work area of possible electricity hazards, such as ungrounded power extension

cables, missing safety grounds, and wet floors.

Locate the emergency power-off switch in the room before installation so you can quickly shut

power off when an electrical accident occurs.

Remove all external cables, including power cords, before moving the chassis.

Do not work alone when the switch has power.

Before performing a task that is hazardous when power is present, make sure the switch is

completely powered off.

Moving safety

!

Do not hold the handle of

a fan tray, a power supply, or a module, or the air vents of the chassis

. Any attempt to move the switch with these parts might cause equipment damage

Remove power supplies, modules, and all external cables, including the power cords, before moving

the chassis. As a best practice, use a mechanical lift, such as forklift truck, to move the chassis.

If no mechanical lift is used, follow these guidelines to move the chassis:

Cooperate with multiple people to move the chassis.

Lift the chassis by using the chassis handles or by supporting the bottom from the two sides.

Lift and put down the chassis slowly and never move suddenly.