10

Before the use

Please read through the instructions

carefully before using the unit and

carefully note the safety advice.

Always keep this manual accessible

to any users of the drill.

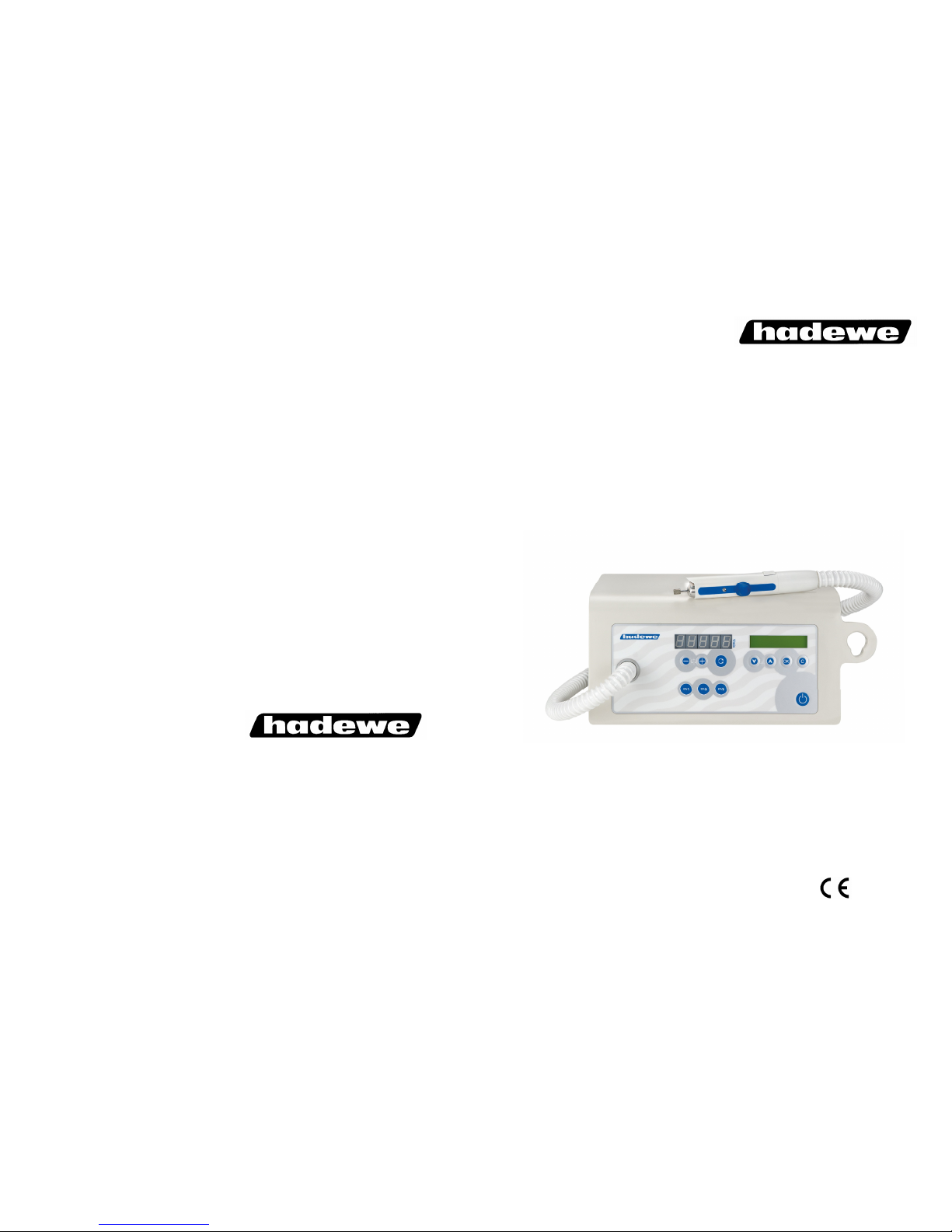

Area of application

This device should only be used by

people who have completed a foot-

care qualification. Before use the

operator should make themselves

familiar with the device by reading

this manual or being instructed by

another. The device must only be

used in closed spaces. It may be

used in hospitals, in a commercial

environment or in homes. The de-

vice is not intended for use in oper-

ating rooms.

The control unit can be set up in a

cabinet, or can be used as a porta-

ble unit (i.g. in a carry case). It is

suitable for the following scopes:

•Footcare: Milling, trimming and

polishing. (Attention: The suction

must be in operation during foot

care).

•Manicure: Grinding, milling and

polishing works.

The devise is determined of

operating rotating instruments,

which will not penetrate the skin

or murcous membrane if used

appropriate, but could evoke

damages accidently.

Caution: In the area of pedicure

you have to work with suction

techniques

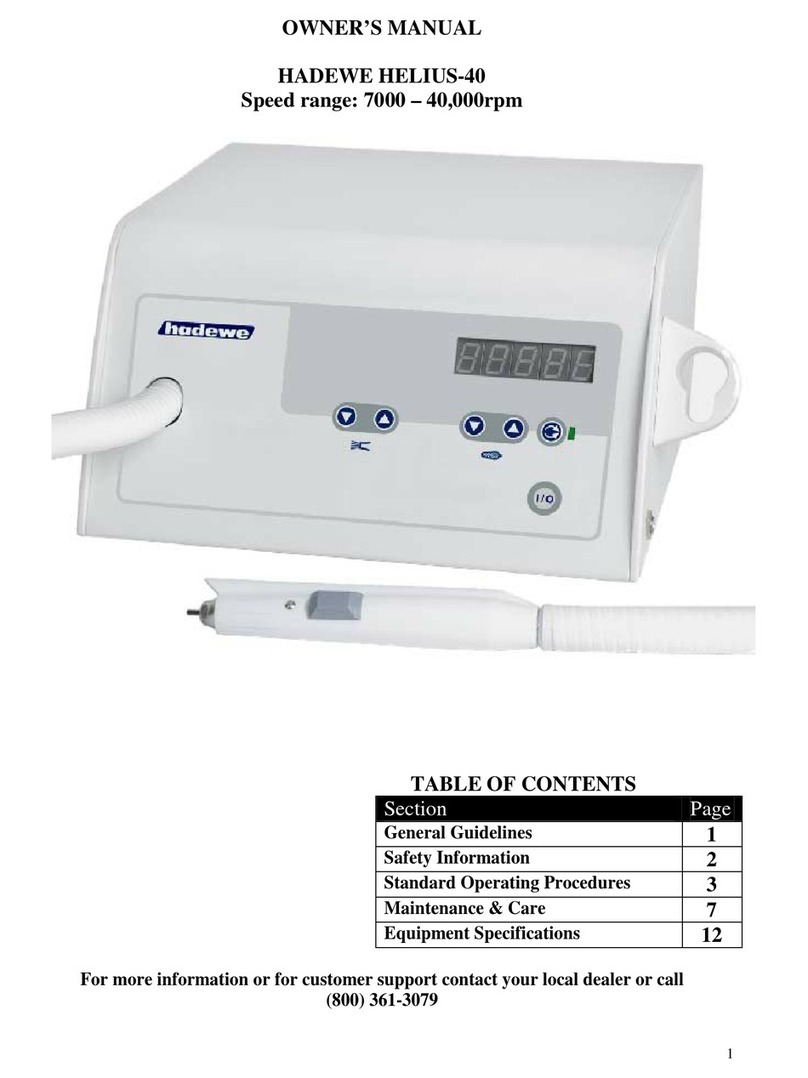

Operation

The working area must conform to

the conditions described. Set up the

unit in such a way, that the air slits

are not blocked and the extracted

air can escape well. To guarantee

unhindered air flow there must a

gap of at least 12cm to the right of

the device. Position the device so

that the operating buttons are easy

to reach and the outlet of the hose

is a maximum distance of 60cm

from the patient's foot. The unit

should be 30 - 90cm from the floor.

Image: Example of positioning of foot care unit

in treatment room.

Image: Bird's eye view of work area

If you have a foot switch insert its

plug into the port on the right of the

device which displays this symbol

19

Maintenance & Care

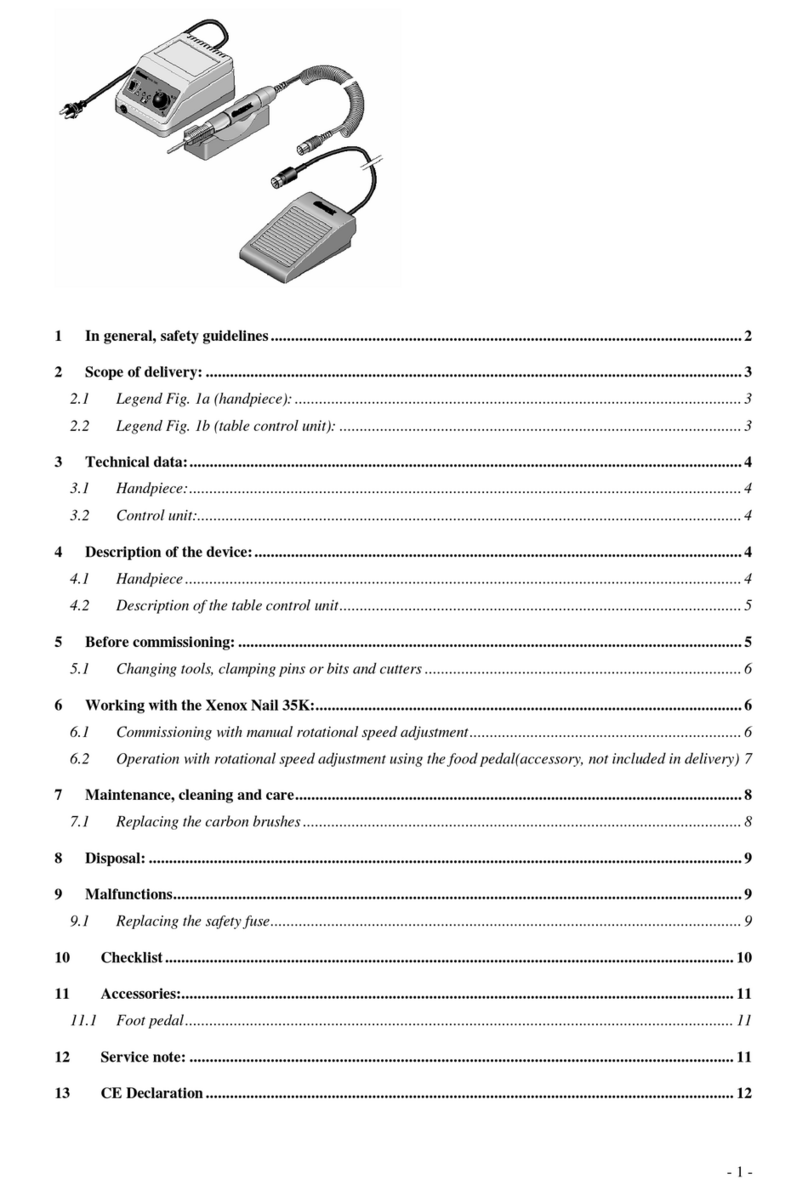

Cleaning the chuck

Because of the additional protection

washer (see right), not much dirt is

usually entering the handpiece. In

the process of time, some dirt might

collect itself within the handpiece,

and might affect its functions.

Therefore the chuck has to be

cleaned monthly.

Dismantle the chuck:

Screw off the top of the handpiece

with the spanner shown in the pic-

ture:

Now clean the inside of the hand-

piece and the top with a dry brush.

For opening the chuck, push the

button forward.

Set the screw spanner (wrench) on

the axle and hold it tight. Now use

the front of the second spanner to

unscrew the chuck.

To assemble the chuck follow the

steps in reverse order. Make sure

that the chuck is opened during the

assembly (the handpiece button

must be in forward position), and is

firmly applied afterwards.

Cleaning the chuck

Soak the chuck in ethyl alcohol or a

special cleaning liquid for tools.

Clean the slits and the hole of the

chuck with a dry scrubber or brush.

Rinse the chuck very well, and

make sure you let it dry well after-

wards.

Cover your index finger with a very

little amount (just a drop) of oil and

rub in between your thumb and

index finger. Now dab off the oil til

your finger is only covered with a

very thin film of oil. Now move the

chuck in between your thumb and

pointer. There should be only a very

thin film of oil left on the chuck.

Please act according to the saying:

Less is more!