hadewe Veloria Chrome User manual

Other hadewe Pedicure Spa manuals

hadewe

hadewe Azuras CHROME User manual

hadewe

hadewe Veloria MD User manual

hadewe

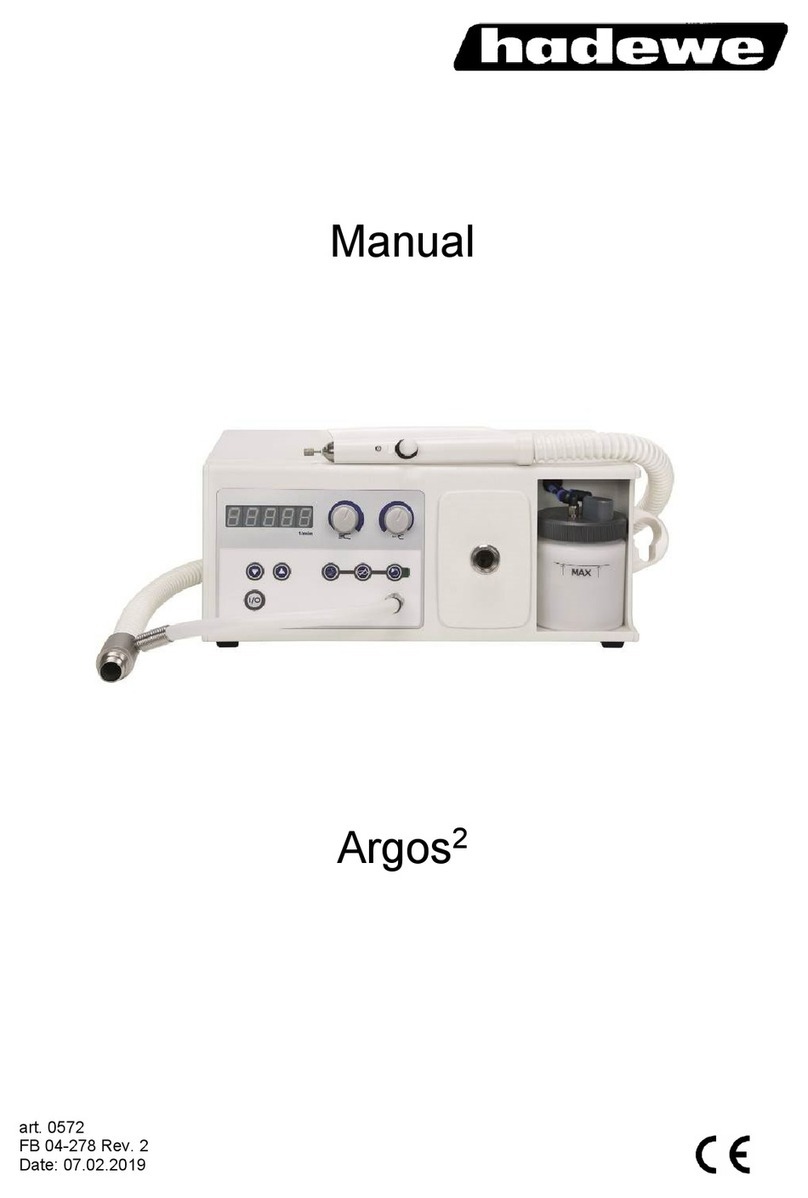

hadewe Argos2 User manual

hadewe

hadewe Medeas User manual

hadewe

hadewe Auroria MD User manual

hadewe

hadewe Azuras PLUS User manual

hadewe

hadewe HELIUS-40 User manual

hadewe

hadewe Veloria User manual

hadewe

hadewe Helius 22 User manual

hadewe

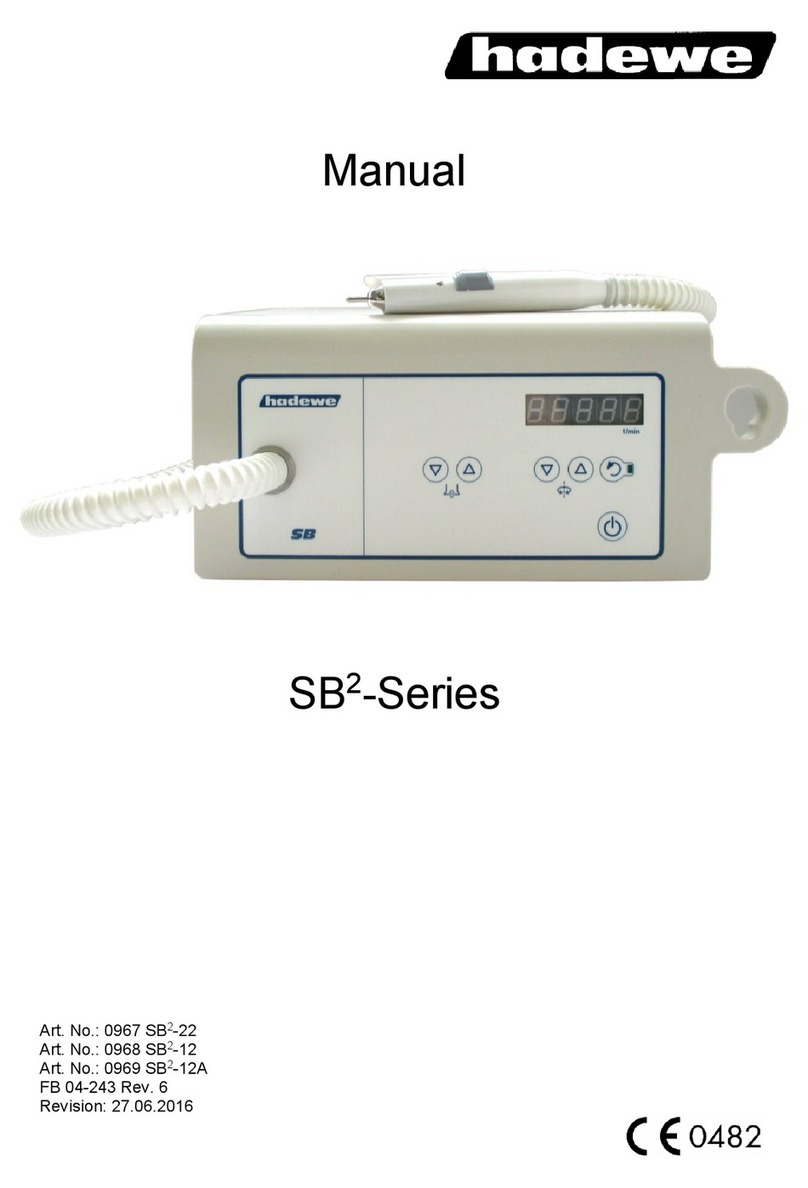

hadewe SB2 Series User manual

Popular Pedicure Spa manuals by other brands

Remington

Remington PFS-600 Use & care guide

j&a

j&a Cleo AX installation guide

European Touch

European Touch RINATO XL SPA owner's manual

HoMedics

HoMedics BubbleBliss FB-30 Instruction manual and warranty

HoMedics

HoMedics JetSpa Elite FB-300 Instruction manual and warranty

HoMedics

HoMedics BubbleSpa BL-150 Instruction manual and warranty