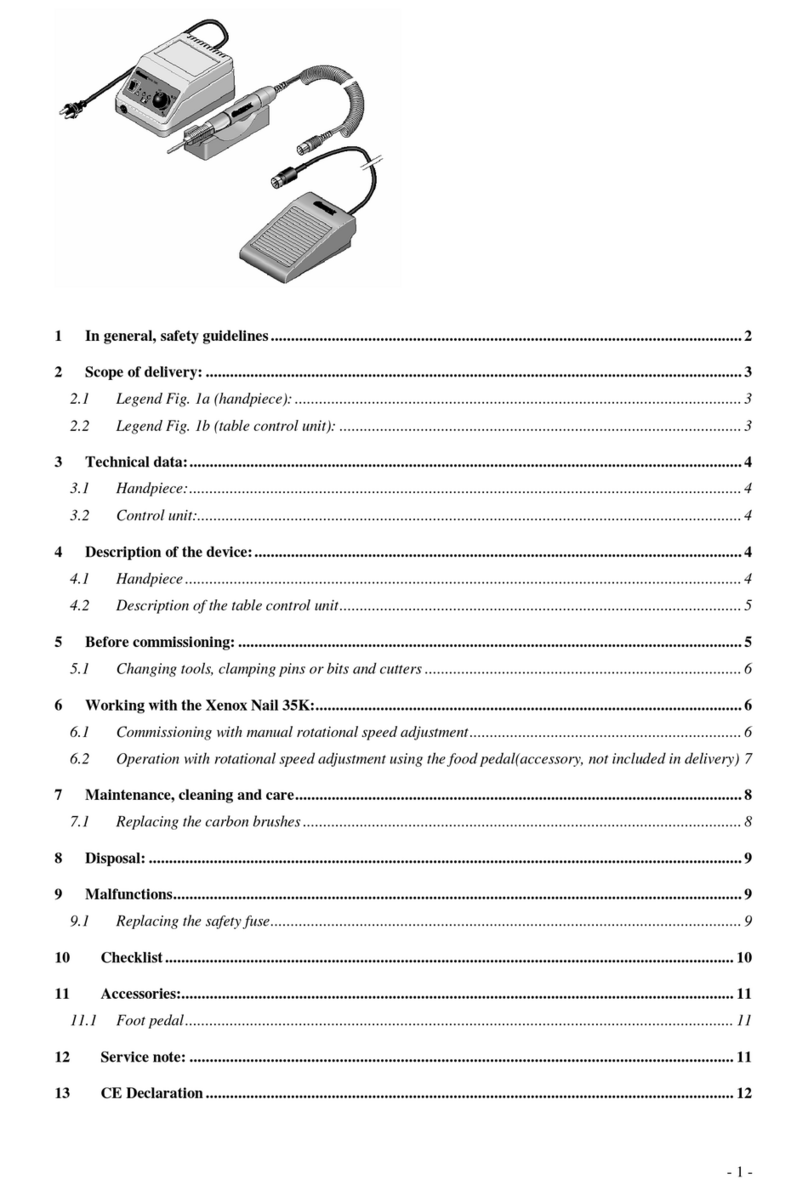

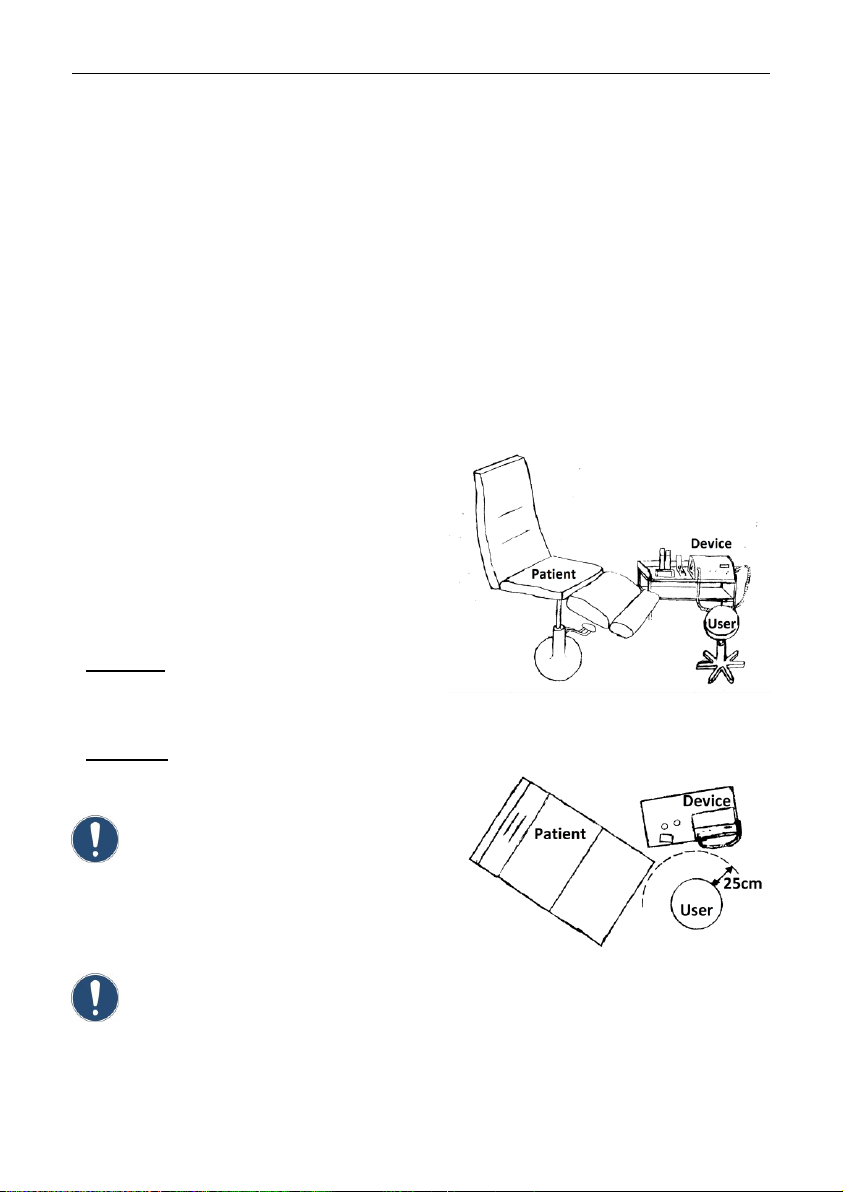

The equipment should only be

used by trained operators.

The installation of the working

area has to correspond to the

relevant regulations. Set up

the unit in such a way, that the air slits

are not blocked and the extracted air

can escape well.

To avoid the risk of electrocu-

tion only connect the device to

the mains power supply.

If you pull the power plug it will

stop the connection to the

mains power supply. Set up

the unit so that the power plug is always

accessible. The power switch should

also always be easily accessible.

Only switch on the unit, if the

handpiece rests secured in the

handpiece holder, or if you

hold it safely in your hand.

Prevent any liquids from

entering into the control unit,

since this could damage the

electronic elements.

Clean the outside of the box only with a

damped cloth. Make sure, that you have

unplugged the unit before.

Only when pulling the mains

cable, you can ensure that the

device will be completely

disconnected from mains.

Check the mains cable regularly for

damages and in case of such, have it

be changed or repaired by an author-

ized service center.

Prevent your hair from

wrapping itself around moving

parts. If applicable, wear a

hair net.

When working with materials,

which might create dust or

moisture, use a drilling unit

with suction or spray tech-nique. Wear

a nose and mouth protec-tion. Always

follow the safety instruc-tions, provided

by the manufacturer of the materials

being formed and used.

For safety reasons you must

always wear disposable

gloves and protective glasses

when operating this unit. In addition, a

face mask conforming to EN 14683 type

IIR or EN 149 FFP 2 must also be worn.

Ensure that the patient’s foot

and the handpiece are held

firmly in place during the

operation. To prevend injury, work with

extreme caution on the foot of the

patient, and use only light pressure

To ensure that the bur/ tool

sits firmly in the chuck, do not

work with tools which:

•have an oily shaft

•are worn

•are bent

Before using the equipment, assure

that:

•the tool can be pushed far enough

into the chuck

•(Test this with a dipstick and clean

if necessary)