TABLE OF CONTENTS

1ACCIDENT PREVENTION AND SAFETY REGULATION..................................................................1

1.1 Advice for the operator.........................................................................................................................1

1.2 The electrical equipment according to European Standard" CENELEC EN 60204-1"........................1

1.3 Warning labels .....................................................................................................................................1

1.4 Emergencies according to European Standard “CENELEC EN 60204-1”..........................................1

2MACHINE TRANSPORTATION AND INSTALLATION.......................................................................2

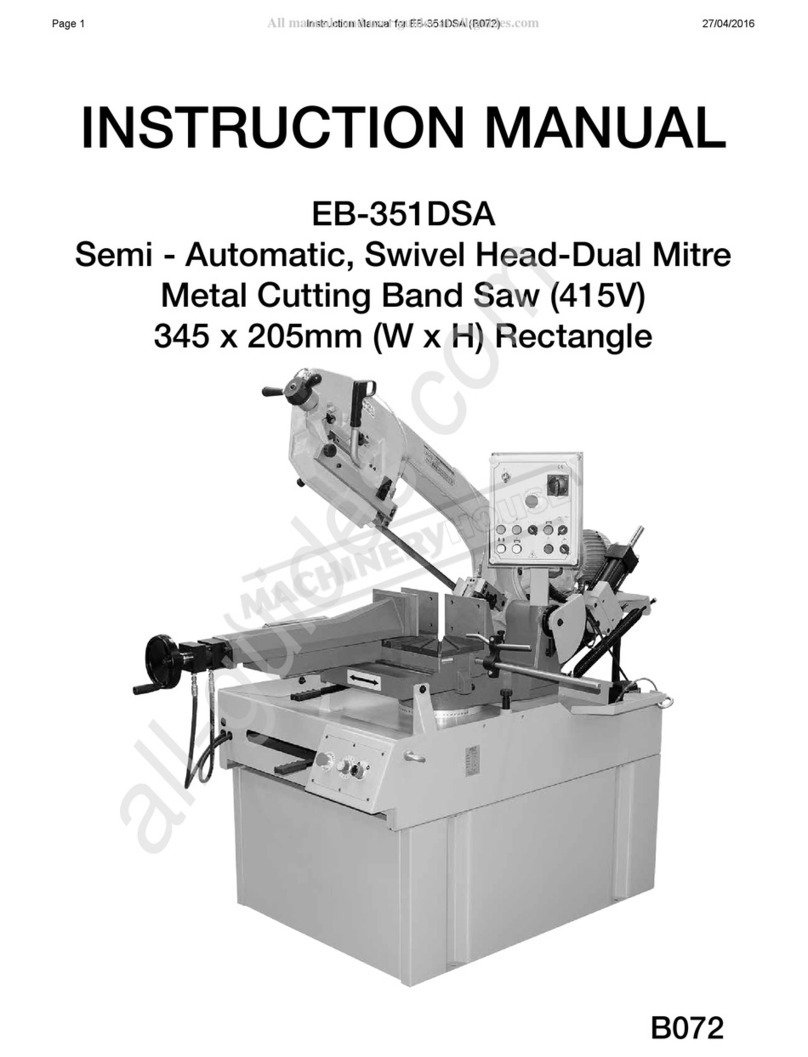

2.1 Machine dimensions ............................................................................................................................2

2.2 Transporting the machine....................................................................................................................2

2.3 Minimum requirements for housing the machine.................................................................................2

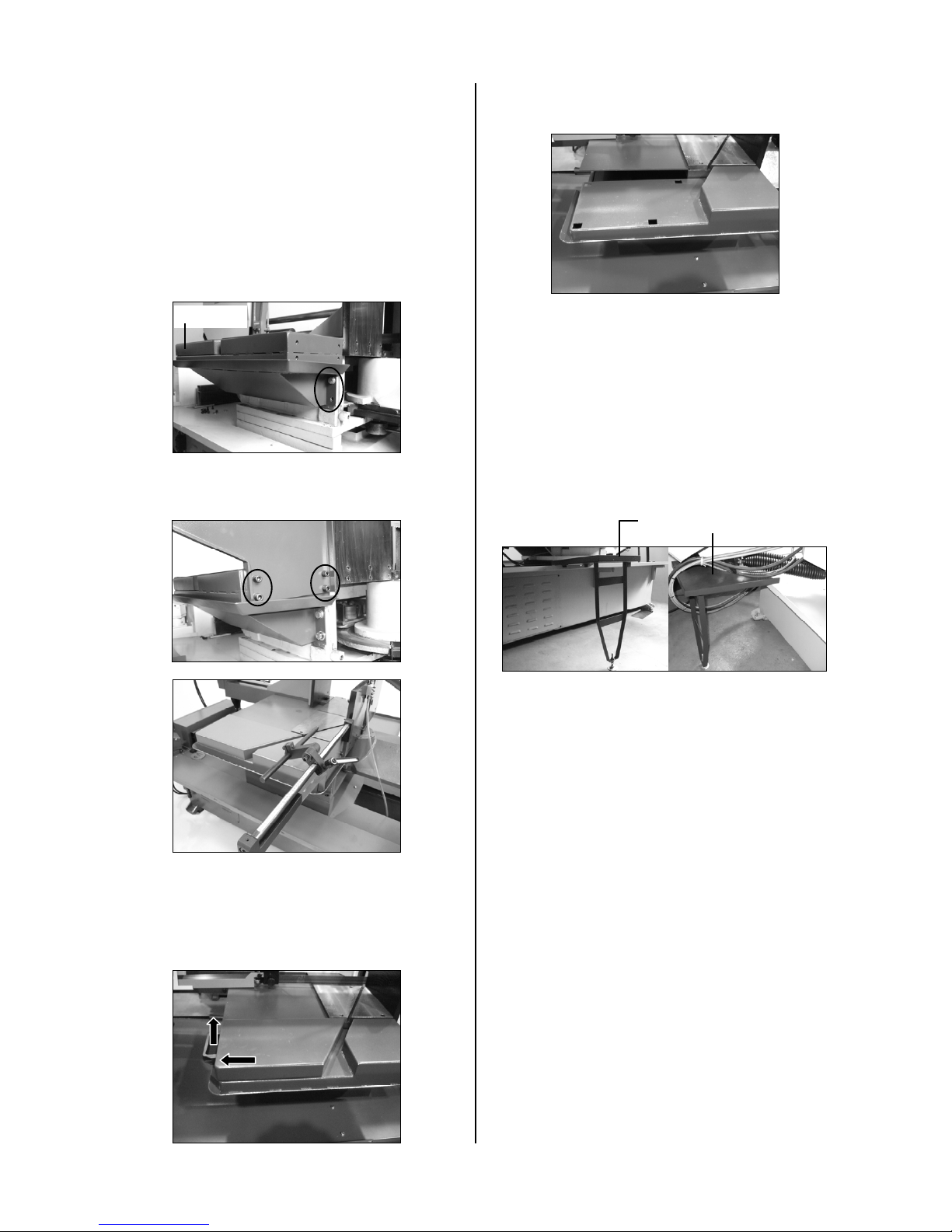

2.4 Installing the rear coolant return tray...................................................................................................2

2.5 Install the outlet tray, length stop device and mobile coolant trays. ....................................................3

2.6 Securing to foundation.........................................................................................................................3

2.7 Leveling the machine...........................................................................................................................3

2.8 Deactivation of machine.......................................................................................................................4

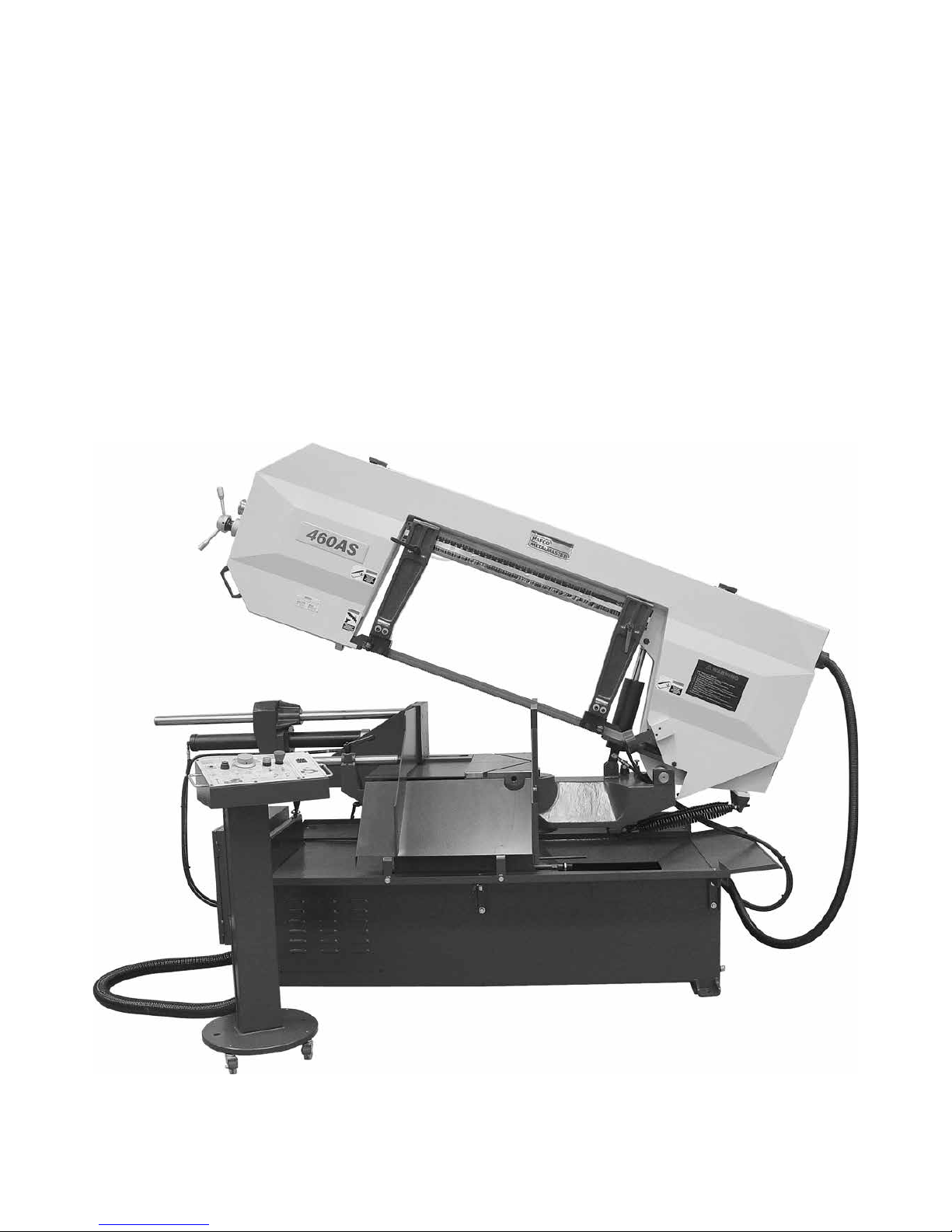

3DESCRIPTION OF MACHINE PARTS................................................................................................4

3.1 Control panel........................................................................................................................................4

3.2 Indicator lights......................................................................................................................................4

3.3 The saw bow........................................................................................................................................5

3.4 The vise system...................................................................................................................................5

3.5 The base..............................................................................................................................................5

3.6 Chip tray...............................................................................................................................................5

3.7 Blade broken micro switch...................................................................................................................5

3.8 Chip brush............................................................................................................................................5

3.9 Blade speed indicator ..........................................................................................................................5

3.10Open Blade Cover Safety Device........................................................................................................6

3.11Speed change dial ...............................................................................................................................6

3.12Blade angle scale.................................................................................................................................6

3.13Attached coolant device.......................................................................................................................6

4SET UP AND PRE-OPERATIONS......................................................................................................6

4.1 Adjusting the tungsten carbide guides.................................................................................................6

4.2 Thrust Roller Adjustment .....................................................................................................................7

4.3 Guide Roller adjustment ......................................................................................................................7

4.4 Adjusting the cutting precision.............................................................................................................7

4.5 Blade tracking adjustment (Manual blade tension type)......................................................................7

4.6 Blade tracking adjustment (Hydraulic blade tension type)...................................................................8

4.7 Placing the saw blade onto the drive wheel and flywheel....................................................................8

4.8 Hydraulic vise pressure........................................................................................................................8

5OPERATION PREPARATIONS...........................................................................................................8

5.1 Setting the stroke limit..........................................................................................................................8

5.2 Positioning the vise..............................................................................................................................9

5.3 Angle cutting ........................................................................................................................................9

5.4 Using the vise.......................................................................................................................................9

5.5 Adjusting the blade speed....................................................................................................................9

5.6 Changing the transmission belt............................................................................................................9

5.7 Selecting Automatic and Manual operation.......................................................................................10

5.8 Changing the blade (Manual blade tension type)..............................................................................10

5.9 Changing the blade (Hydraulic blade tension type)...........................................................................10

5.10Laser guide device (optional).............................................................................................................11

5.11Install the vertical press on the vise jaws for bundle cutting (optional)..............................................11

6OPERATION CYCLE.........................................................................................................................12

6.1 Operation cycle..................................................................................................................................12

6.2 Stopping or emergency stopping.......................................................................................................12

6.3 Automatic shutoff during machine operation .....................................................................................12

7ROUTINE AND SPECIAL MAINTENANCE.......................................................................................13

7.1 Daily maintenance..............................................................................................................................13

7.2 Weekly maintenance..........................................................................................................................13

7.3 Monthly maintenance.........................................................................................................................13

7.4 Six-monthly maintenance...................................................................................................................13

7.5 Oils for lubricating coolant..................................................................................................................13

7.6 Oil disposal.........................................................................................................................................13

7.7 Special maintenance..........................................................................................................................13

7.8 Changing gear oil...............................................................................................................................13

8TECHNICAL CHARACTERISTICS....................................................................................................14

8.1 Table of cutting capacity and technical details ..................................................................................14

8.2 NOISE TESTS ...................................................................................................................................14