7

DANGER: DO NOT TOUCH PIPING

ANDINTERNAL PARTS

Do not touch the refrigerant piping, water piping or

internal parts during and immediately after operation.

The piping and internal parts may be hot or cold

depending on the working condition of the unit.

Your hand may suffer burns or frostbite if you touch

the piping or internal parts. To avoid injury, give the

piping and internal parts time to return to normal

temperature or, if you must touch them, be sure to

wear protective gloves.

Warning:

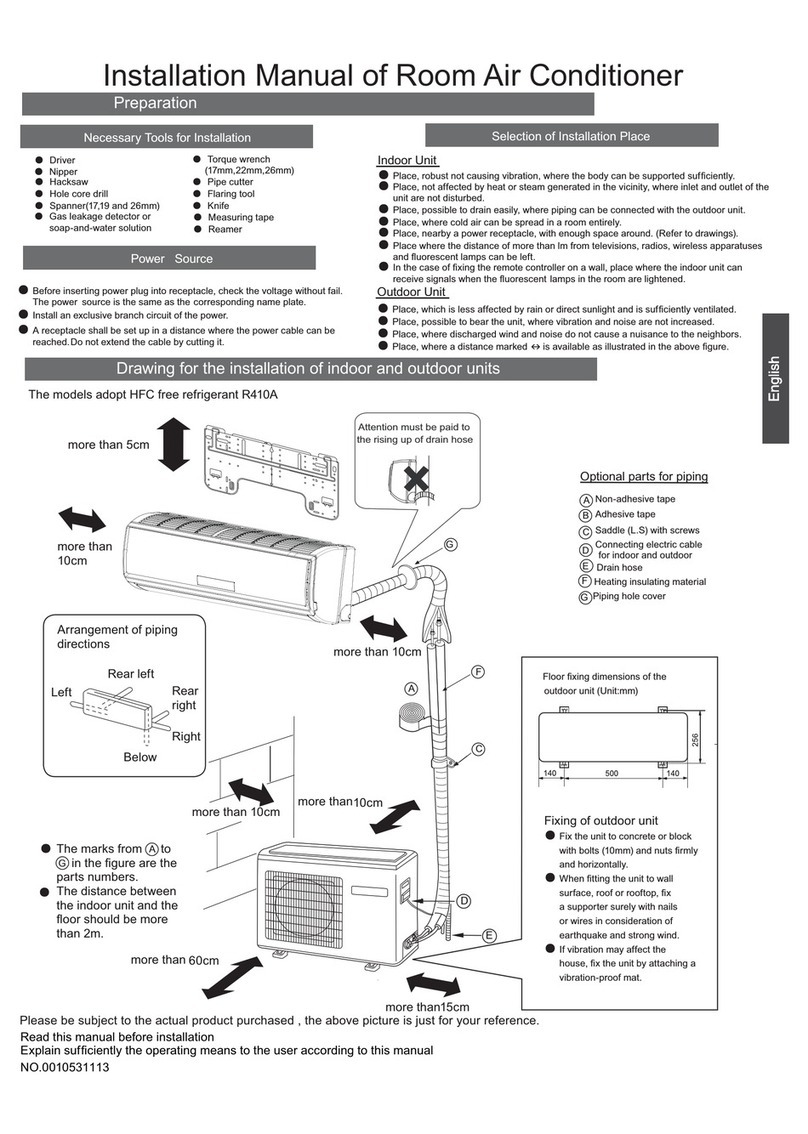

Ask your dealer or qualied personnel to carry out

installation work. Do not install the machine by

yourself. Improper installation may result in water

leakage, electric shocks or re.

Perform installation work in accordance with this

installation manual.

Improper installation may lead to water leakage,

electric shocks or re.

The equipment is not intended for use in a potentially

explosive atmosphere.

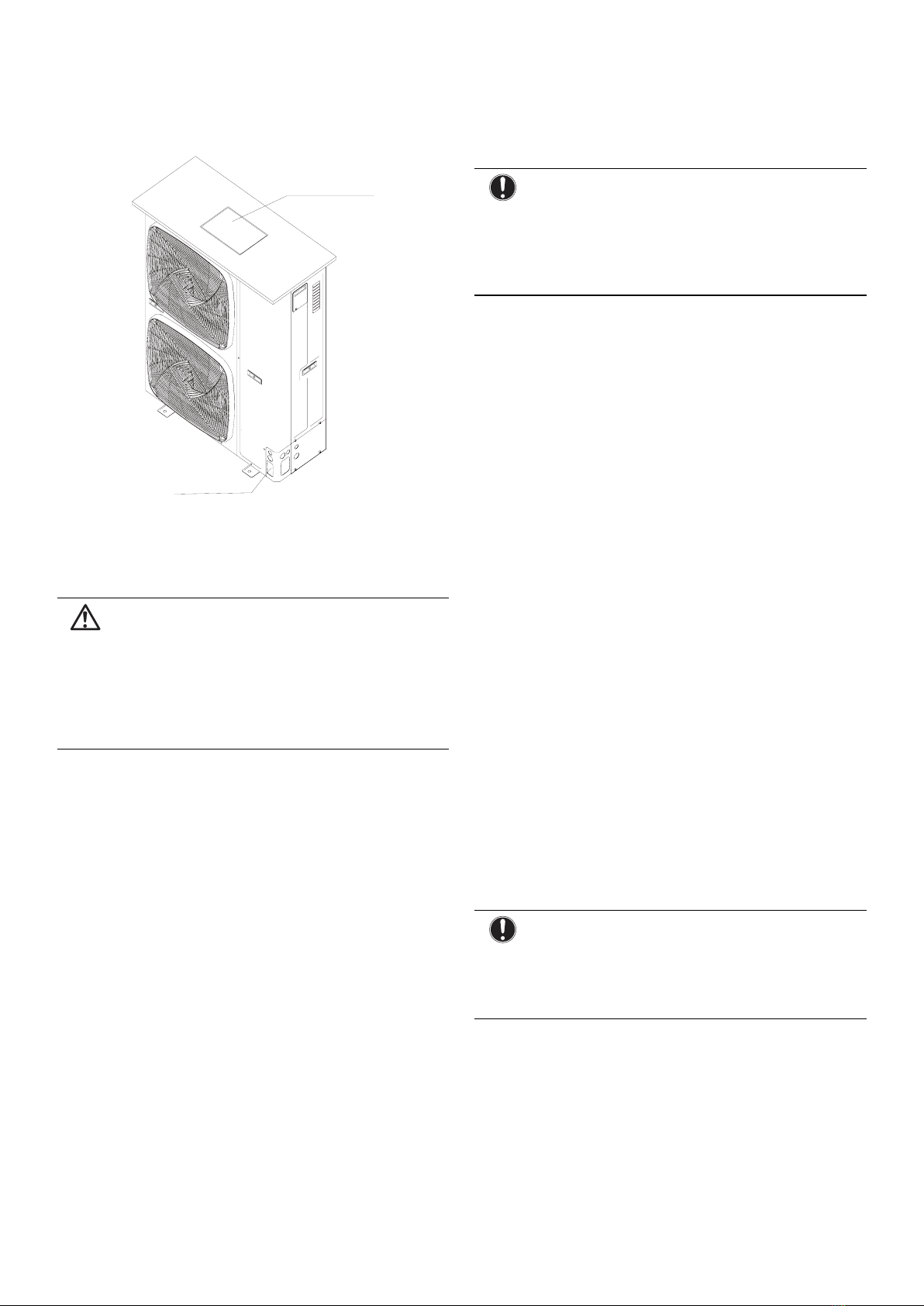

For 1UH series units only.

For year round cooling applications with low indoor

humidity conditions, such as Electronic Data

Processing rooms, contacet yout dealer or see the

engineering databook or the service manual.

Consult your local dealer regarding what to do in case

of refrigerant leakage. When the unit is to be installed in

a small room, it is necessary to take proper measures

so that the amount of any leaked refrigerant does not

exceed the concentration limit in the event of a leakage.

Otherwise, this may lead to an accident due to oxygen

depletion.

Be sure to use only the specied accessories and

parts for installation work.

Failure to use the specied parts may result in water

leakage, electric shocks, re, or the unit falling.

Install the unit on a foundation that can withstand its

weight.

Insufcient strength may result in the fall of equipment

and causing injury.

Carry out the specied installation work in consideration

of strong winds, typhoons, or earthquakes.

Improper installation work may result in accidents due

to fall of equipment.

Make sure that all electrical work is carried out by

qualied personnel according to the applicable legislation

and this installation manual, using a separate circuit.

Insufcient capacity of the power supply circuit or

improper electrical capacity of the power supply

circuit or improper electrical construction may lead to

electric shocks or re.

Make sure that all wiring is secure, using the specied

wires and ensuring that external forces do not act on

the terminal connections or wires.

Incomplete connection or xing may cause a re.

When wiring between the indoor and outdoor units,

and wiring the power supply, form the wires so that

the fronstside panel can be securely fastened.

If the frontside panel is not in place, overheating of

the terminals, electric shocks or a re may be caused.

If refrigerant gas leaks during installation work,

ventilate the area immediately.

Toxic gas may be produced if refrigerant gas comes

into contactwith re.

After completing the installation work, check to make

sure that there is no leakage of refrigerant gas.

Toxic gas may be produced if refrigerant gas leaks

into the room and comes into contact with a source of

re, such as a fan heater, stove or cooker.

When planning to relocate former installed units, you

must rst recover the refrigerant after the pump down

operation.

Never directly touch any accidental leaking refrigerant.

This could result in severe wounds caused by frostbite.

Be sure to install an earth leakage circuit breaker in

accordance with applicable legislation. Failure to do so

may cause electrical shock and re.

Caution:

Earth the unit.

Earthing resistance should be according to applicable

legislation.

Do not connect the earth wire to gas or water pipes,

lightning conductor or telephone earth wire.

Incomplete earthing may cause electric shocks.

Gas pipe.

Lgnition or explosion may occur if the gas leaks. Water

pipe.

Hard vinyl tubes are not effective earths. Lightning

conductor or telephone earth wire. Electric potential

may rise abnormally if struck by a lightning bolt.

Install drain piping according to this installation manual

to ensure good drainage, and insulate the pipe to

prevent condensation.

Improper drain piping may cause water leakage, and

make the fumitures get wet.

Install the indoor and outdoor units, power wire and

connecting wire at least 1 meter away from televisions

or radios to prevent image interference or noise.

(Depending on the radio waves, a distance of 1 meter

may not be sufcient to eliminate the noise.)

Do not rinse the outdoor unit, This may cause electric

shocks or re.

Do not install the unit in places such as the following:

Where there is mist of mineral oil, oil spray or vapour

for example a kitchen.

Plastic parts may deteriorate, and cause them to fall

out or water to leak.